|

|

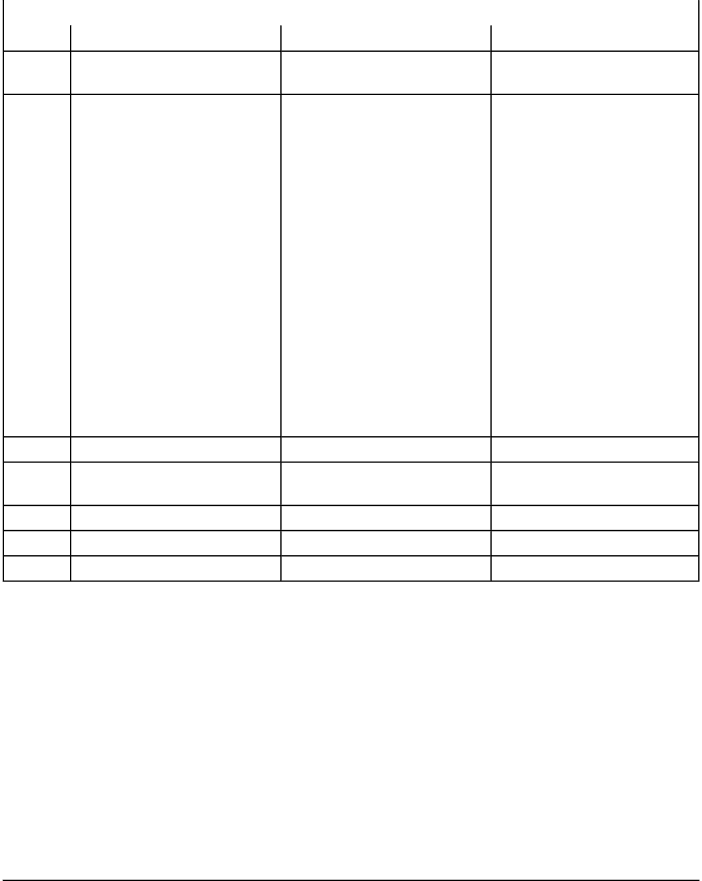

| training checklist |

|

|

|

|

|

|

|

|

|

| Training checklist |

|

|

|

|

|

No. | description | Ok? | date |

1Read operation manual

completely

| Machine layout, location of | |

2 | components, checking of engine | |

| and hydraulic oil levels | |

|

| |

3 | Fuel system, refueling procedure | |

|

| |

4 | Operation of spray and lights | |

|

| |

5 | Operation of controls (machine | |

not running) | ||

| ||

|

| |

6 | Safety controls, safety stop switch | |

operation | ||

| ||

|

| |

7 | Emergency stop procedures | |

|

| |

8 | Startup of machine, | |

engine choke | ||

| ||

|

| |

9 | Maintaining a hover | |

|

| |

10 | Maneuvering | |

|

| |

11 | Pitching |

12Matching blade pitch.

13Concrete fi nishing techniques

14Shutdown of machine

15Lifting of machine (lift loops)

16Machine transport and storage

page 6 — stxd6i