maintenance

Changing Engine Oil And Filter

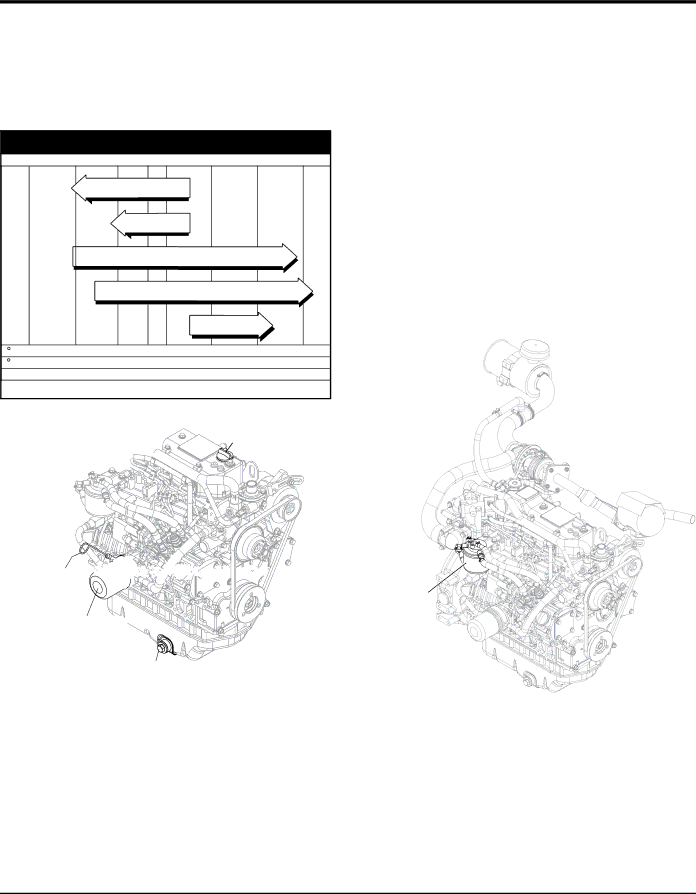

Change the engine oil and filter after the first 50 hours of use, then every 6 months or 250 hours. Refer to Table 6 for recommended oil viscosity. Refer to Figure 25 for location of parts.

Table 6. Recommended Viscosity Grades

10W

20W

SAE 10W-30

SAE 15W-40

# 30

F | 0 | 20 | 32 40 | 60 |

| 80 | 100 |

C | 0 | 10 | 20 | 30 | 40 | ||

TEMPERATURE RANGE EXPECTED BEFORE NEXT OIL CHANGE | |||||||

|

|

|

| OIL FILLER |

| ||

|

|

|

|

| CAP |

|

|

DIP STICK![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

OIL FILTER ![]()

![]()

![]()

OIL DRAIN

PLUG

Figure 25. Engine Oil Service Components

1.Remove the oil filler cap while draining the oil to allow the engine to drain easily.

2.Remove the drain plug to drain the oil.

3.After oil is sufficiently drained, securely tighten the drain plug.

4.Using a filter wrench, turn the oil filter counterclockwise to remove.

5.Clean sealing surface on engine where filter mounts.

6.Coat the seal of the new oil filter with clean engine oil. Install new filter first by hand until it contacts the engine sealing surface. Tighten it another 3/4 turn using the filter wrench.

7.Fill engine with oil until it shows between the upper and lower limits on the dipstick. Do Not overfill.

8.Run the engine briefly for several minutes. Watch for oil leakage. Shut the engine down and allow it to sit for several minutes. Top off the oil to the upper limit on the dipstick.

Fuel Filter

1.Replace the engine fuel filter element (Figure 26) every 500 hours.

FUEL FILTER

Figure 26. Fuel Filter

STXD6i