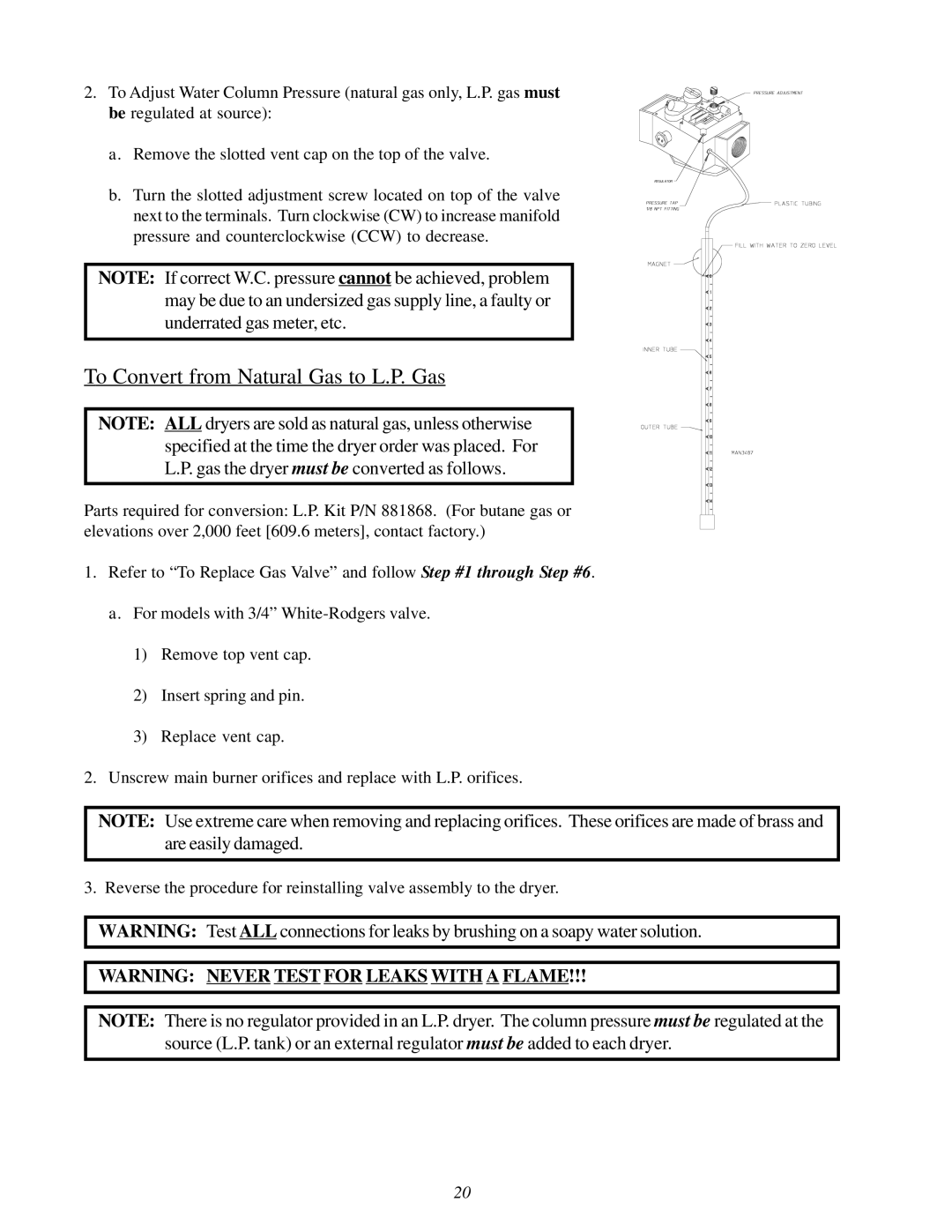

2. To Adjust Water Column Pressure (natural gas only, L.P. gas must be regulated at source):

a. Remove the slotted vent cap on the top of the valve.

b.Turn the slotted adjustment screw located on top of the valve next to the terminals. Turn clockwise (CW) to increase manifold pressure and counterclockwise (CCW) to decrease.

NOTE: If correct W.C. pressure cannot be achieved, problem may be due to an undersized gas supply line, a faulty or underrated gas meter, etc.

To Convert from Natural Gas to L.P. Gas

NOTE: ALL dryers are sold as natural gas, unless otherwise specified at the time the dryer order was placed. For L.P. gas the dryer must be converted as follows.

Parts required for conversion: L.P. Kit P/N 881868. (For butane gas or elevations over 2,000 feet [609.6 meters], contact factory.)

1.Refer to “To Replace Gas Valve” and follow Step #1 through Step #6. a. For models with 3/4”

1)Remove top vent cap.

2)Insert spring and pin.

3)Replace vent cap.

2.Unscrew main burner orifices and replace with L.P. orifices.

NOTE: Use extreme care when removing and replacing orifices. These orifices are made of brass and are easily damaged.

3. Reverse the procedure for reinstalling valve assembly to the dryer.

WARNING: Test ALL connections for leaks by brushing on a soapy water solution.

WARNING: NEVER TEST FOR LEAKS WITH A FLAME!!!

NOTE: There is no regulator provided in an L.P. dryer. The column pressure must be regulated at the source (L.P. tank) or an external regulator must be added to each dryer.

20