OPERATION

OPERATION

FRAME ASSEMBLY

•Ensure all bolts and screws are in position and are properly torqued.

•Ensure all pins are in place and fastened with screws.

•Ensure frame is properly mounted to tractor and hardware is properly installed and tightened.

BOOM ARM ASSEMBLY

•Inspect condition of each arm section weldment

•Ensure all pins are in place.

•Ensure all bolts and screws are properly installed.

•Check condition of teflon bushings at boom pivot points.

•Ensure each hydraulic cylinder is installed and retained correctly. Ensure the proper size pins are used to retain the cylinders in place and are secured properly.

•Ensure that all joints are lubricated. See Maintenance Section for Lubrication Chart.

Never attempt to lubricate, adjust, or remove material from the Implement while it is in motion or while tractor engine is running.

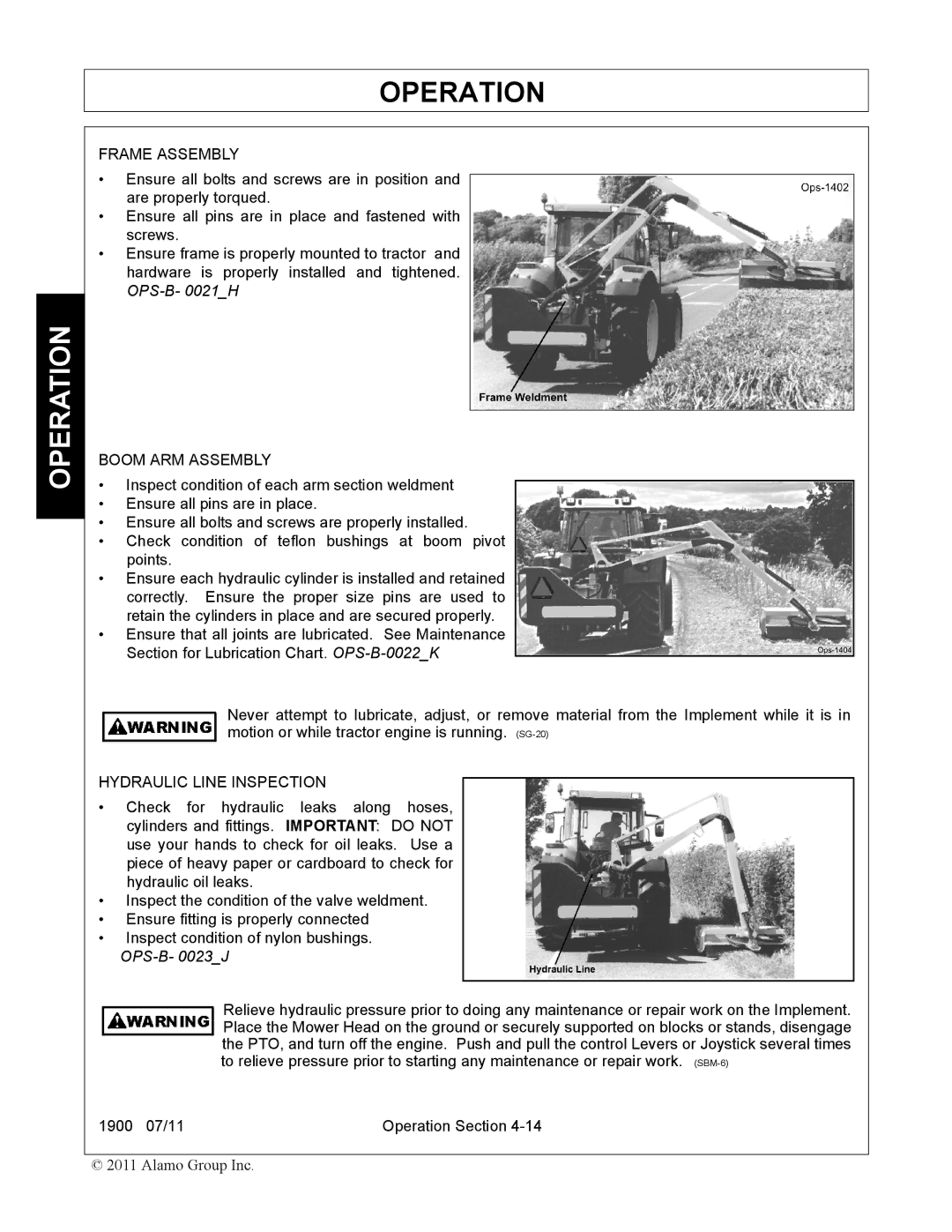

HYDRAULIC LINE INSPECTION

•Check for hydraulic leaks along hoses, cylinders and fittings. IMPORTANT: DO NOT use your hands to check for oil leaks. Use a piece of heavy paper or cardboard to check for hydraulic oil leaks.

•Inspect the condition of the valve weldment.

•Ensure fitting is properly connected

•Inspect condition of nylon bushings.

OPS-B- 0023_J

Relieve hydraulic pressure prior to doing any maintenance or repair work on the Implement. Place the Mower Head on the ground or securely supported on blocks or stands, disengage the PTO, and turn off the engine. Push and pull the control Levers or Joystick several times to relieve pressure prior to starting any maintenance or repair work.

1900 07/11 | Operation Section |

© 2011 Alamo Group Inc.