MAINTENANCE

PTO LUBRICATION

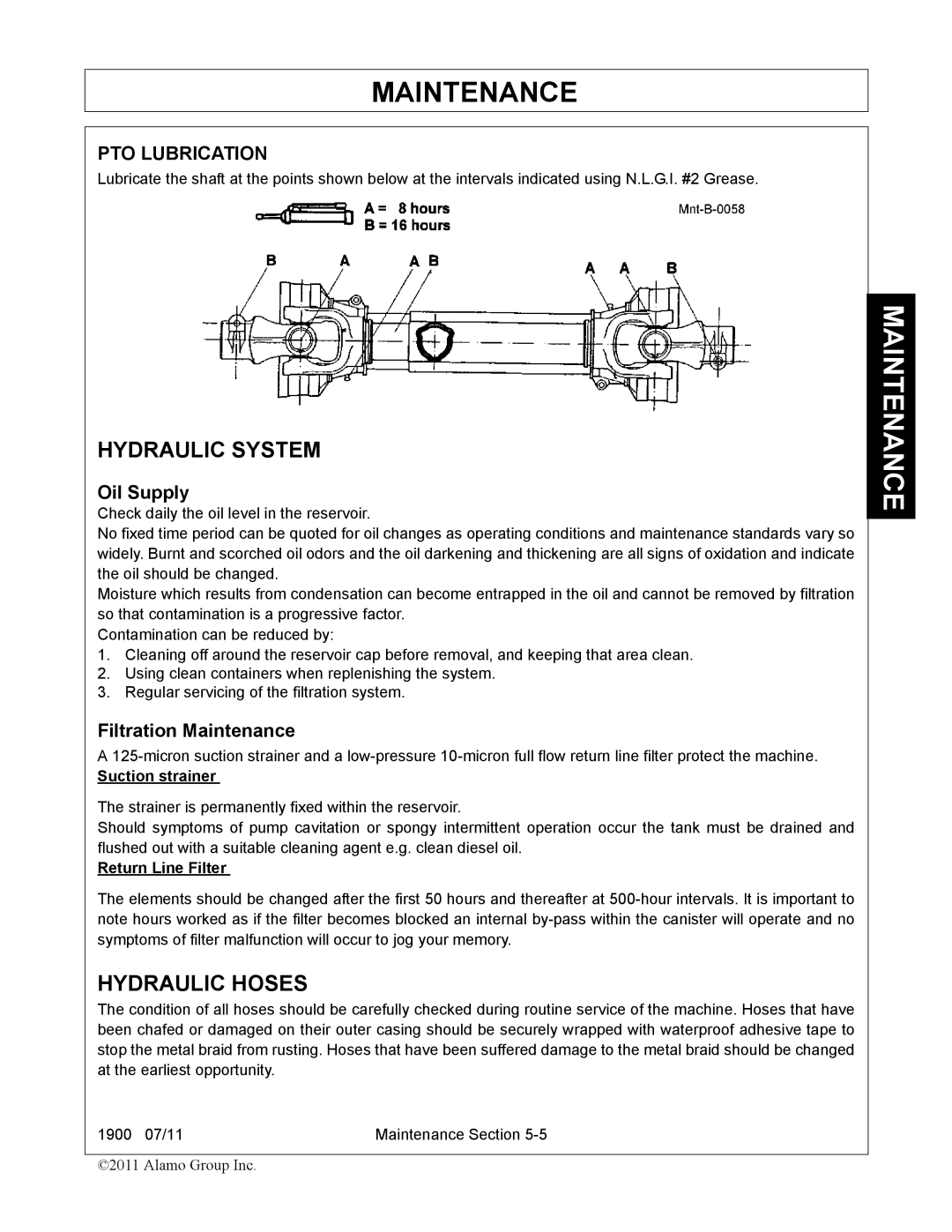

Lubricate the shaft at the points shown below at the intervals indicated using N.L.G.I. #2 Grease.

HYDRAULIC SYSTEM

Oil Supply

Check daily the oil level in the reservoir.

No fixed time period can be quoted for oil changes as operating conditions and maintenance standards vary so widely. Burnt and scorched oil odors and the oil darkening and thickening are all signs of oxidation and indicate the oil should be changed.

Moisture which results from condensation can become entrapped in the oil and cannot be removed by filtration so that contamination is a progressive factor.

Contamination can be reduced by:

1.Cleaning off around the reservoir cap before removal, and keeping that area clean.

2.Using clean containers when replenishing the system.

3.Regular servicing of the filtration system.

Filtration Maintenance

A

Suction strainer

The strainer is permanently fixed within the reservoir.

Should symptoms of pump cavitation or spongy intermittent operation occur the tank must be drained and flushed out with a suitable cleaning agent e.g. clean diesel oil.

Return Line Filter

The elements should be changed after the first 50 hours and thereafter at

HYDRAULIC HOSES

The condition of all hoses should be carefully checked during routine service of the machine. Hoses that have been chafed or damaged on their outer casing should be securely wrapped with waterproof adhesive tape to stop the metal braid from rusting. Hoses that have been suffered damage to the metal braid should be changed at the earliest opportunity.

1900 07/11 | Maintenance Section |

©2011 Alamo Group Inc.