OPERATION

OPERATION

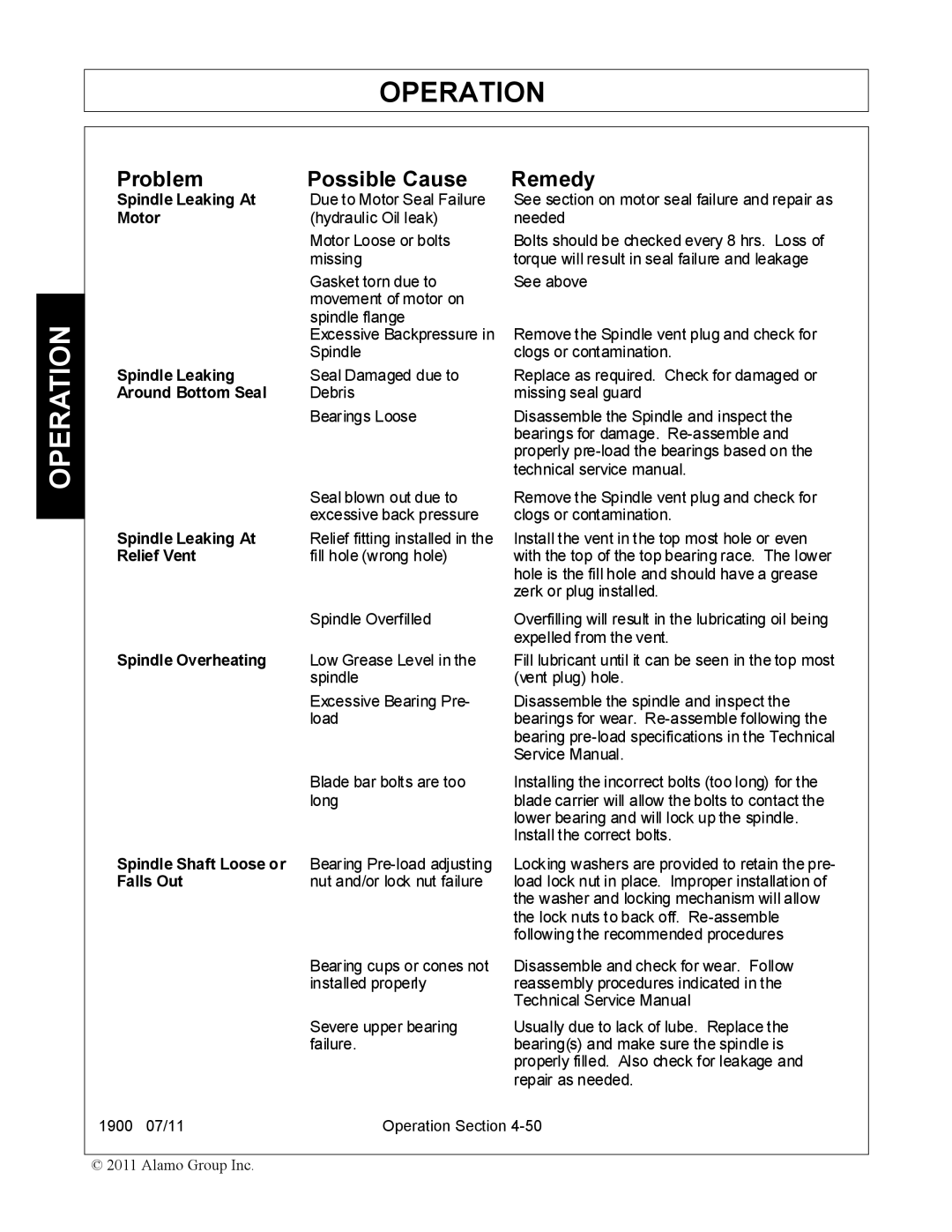

Problem | Possible Cause | Remedy |

Spindle Leaking At | Due to Motor Seal Failure | See section on motor seal failure and repair as |

Motor | (hydraulic Oil leak) | needed |

| Motor Loose or bolts | Bolts should be checked every 8 hrs. Loss of |

| missing | torque will result in seal failure and leakage |

| Gasket torn due to | See above |

| movement of motor on |

|

| spindle flange |

|

| Excessive Backpressure in | Remove the Spindle vent plug and check for |

| Spindle | clogs or contamination. |

Spindle Leaking | Seal Damaged due to | Replace as required. Check for damaged or |

Around Bottom Seal | Debris | missing seal guard |

| Bearings Loose | Disassemble the Spindle and inspect the |

|

| bearings for damage. |

|

| properly |

|

| technical service manual. |

| Seal blown out due to | Remove the Spindle vent plug and check for |

| excessive back pressure | clogs or contamination. |

Spindle Leaking At | Relief fitting installed in the | Install the vent in the top most hole or even |

Relief Vent | fill hole (wrong hole) | with the top of the top bearing race. The lower |

|

| hole is the fill hole and should have a grease |

|

| zerk or plug installed. |

| Spindle Overfilled | Overfilling will result in the lubricating oil being |

|

| expelled from the vent. |

Spindle Overheating | Low Grease Level in the | Fill lubricant until it can be seen in the top most |

| spindle | (vent plug) hole. |

| Excessive Bearing Pre- | Disassemble the spindle and inspect the |

| load | bearings for wear. |

|

| bearing |

|

| Service Manual. |

| Blade bar bolts are too | Installing the incorrect bolts (too long) for the |

| long | blade carrier will allow the bolts to contact the |

|

| lower bearing and will lock up the spindle. |

|

| Install the correct bolts. |

Spindle Shaft Loose or | Bearing | Locking washers are provided to retain the pre- |

Falls Out | nut and/or lock nut failure | load lock nut in place. Improper installation of |

|

| the washer and locking mechanism will allow |

|

| the lock nuts to back off. |

|

| following the recommended procedures |

| Bearing cups or cones not | Disassemble and check for wear. Follow |

| installed properly | reassembly procedures indicated in the |

|

| Technical Service Manual |

| Severe upper bearing | Usually due to lack of lube. Replace the |

| failure. | bearing(s) and make sure the spindle is |

|

| properly filled. Also check for leakage and |

|

| repair as needed. |

1900 07/11 | Operation Section | |

|

|

|

© 2011 Alamo Group Inc. |

|

|