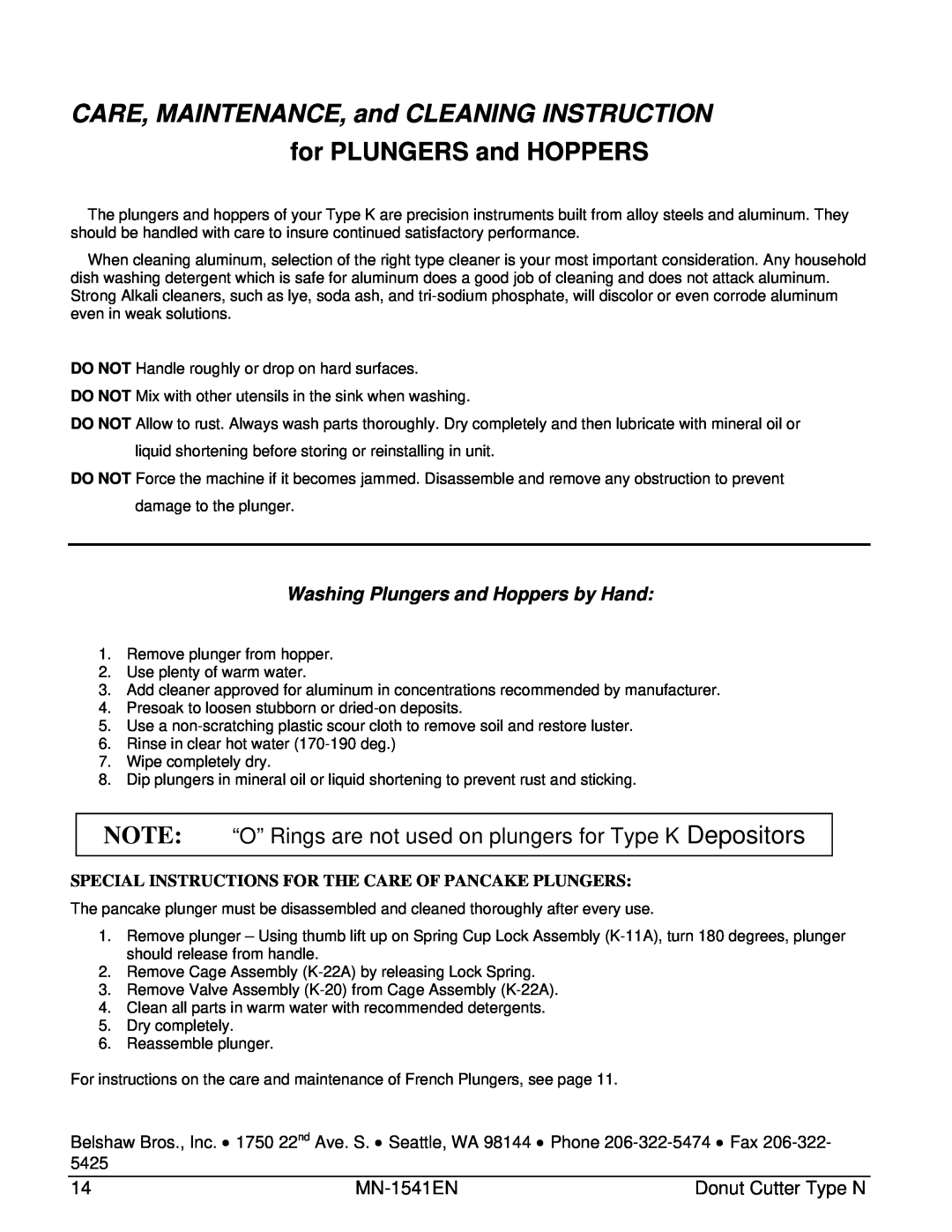

CARE, MAINTENANCE, and CLEANING INSTRUCTION

for PLUNGERS and HOPPERS

The plungers and hoppers of your Type K are precision instruments built from alloy steels and aluminum. They should be handled with care to insure continued satisfactory performance.

When cleaning aluminum, selection of the right type cleaner is your most important consideration. Any household dish washing detergent which is safe for aluminum does a good job of cleaning and does not attack aluminum. Strong Alkali cleaners, such as lye, soda ash, and

DO NOT Handle roughly or drop on hard surfaces.

DO NOT Mix with other utensils in the sink when washing.

DO NOT Allow to rust. Always wash parts thoroughly. Dry completely and then lubricate with mineral oil or liquid shortening before storing or reinstalling in unit.

DO NOT Force the machine if it becomes jammed. Disassemble and remove any obstruction to prevent damage to the plunger.

Washing Plungers and Hoppers by Hand:

1.Remove plunger from hopper.

2.Use plenty of warm water.

3.Add cleaner approved for aluminum in concentrations recommended by manufacturer.

4.Presoak to loosen stubborn or

5.Use a

6.Rinse in clear hot water

7.Wipe completely dry.

8.Dip plungers in mineral oil or liquid shortening to prevent rust and sticking.

NOTE: “O” Rings are not used on plungers for Type K Depositors

SPECIAL INSTRUCTIONS FOR THE CARE OF PANCAKE PLUNGERS:

The pancake plunger must be disassembled and cleaned thoroughly after every use.

1.Remove plunger – Using thumb lift up on Spring Cup Lock Assembly

2.Remove Cage Assembly

3.Remove Valve Assembly

4.Clean all parts in warm water with recommended detergents.

5.Dry completely.

6.Reassemble plunger.

For instructions on the care and maintenance of French Plungers, see page 11.

Belshaw Bros., Inc. 1750 22nd Ave. S. Seattle, WA 98144 Phone

14 | Donut Cutter Type N |