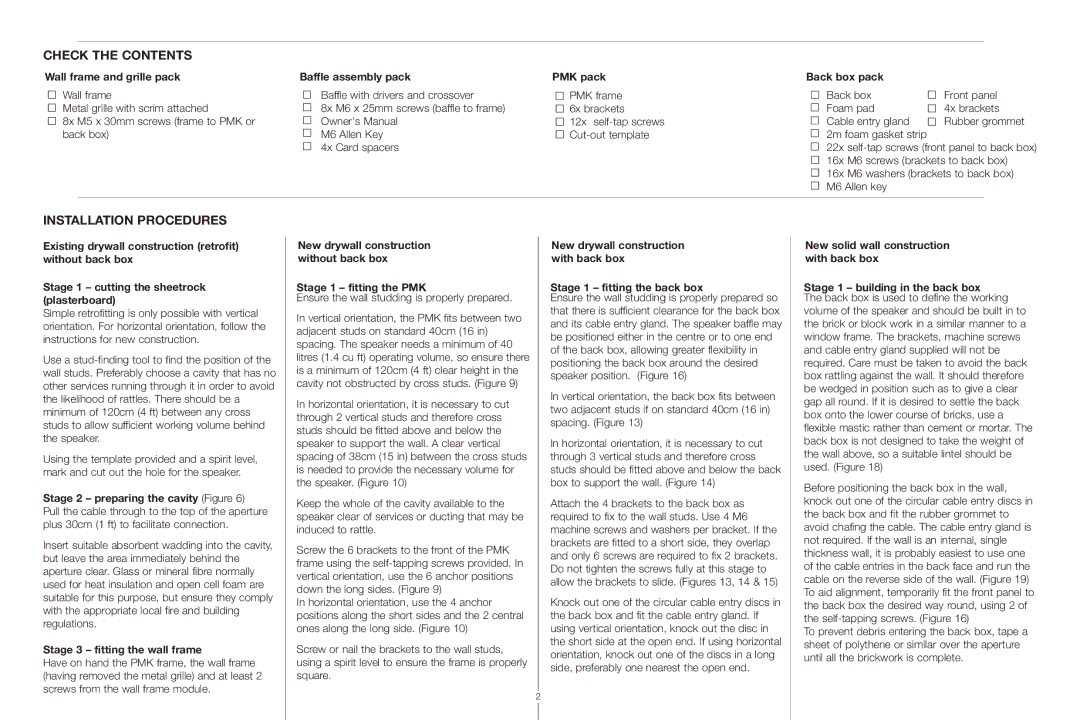

CHECK THE CONTENTS

Wall frame and grille pack | Baffle assembly pack | PMK pack | Back box pack |

Wall frame

Metal grille with scrim attached

8x M5 x 30mm screws (frame to PMK or back box)

Baffle with drivers and crossover

8x M6 x 25mm screws (baffle to frame) Owner's Manual

M6 Allen Key

4x Card spacers

PMK frame

6x brackets

12x

Back box![]() Foam pad

Foam pad ![]() Cable entry gland

Cable entry gland ![]() 2m foam gasket strip

2m foam gasket strip

22x

16x M6 washers (brackets to back box)

M6 Allen key

INSTALLATION PROCEDURES

Existing drywall construction (retrofit) without back box

Stage 1 – cutting the sheetrock (plasterboard)

Simple retrofitting is only possible with vertical orientation. For horizontal orientation, follow the instructions for new construction.

Use a

Using the template provided and a spirit level, mark and cut out the hole for the speaker.

Stage 2 – preparing the cavity (Figure 6)

Pull the cable through to the top of the aperture plus 30cm (1 ft) to facilitate connection.

Insert suitable absorbent wadding into the cavity, but leave the area immediately behind the aperture clear. Glass or mineral fibre normally used for heat insulation and open cell foam are suitable for this purpose, but ensure they comply with the appropriate local fire and building regulations.

Stage 3 – fitting the wall frame

Have on hand the PMK frame, the wall frame (having removed the metal grille) and at least 2 screws from the wall frame module.

New drywall construction without back box

Stage 1 – fitting the PMK

Ensure the wall studding is properly prepared.

In vertical orientation, the PMK fits between two adjacent studs on standard 40cm (16 in) spacing. The speaker needs a minimum of 40 litres (1.4 cu ft) operating volume, so ensure there is a minimum of 120cm (4 ft) clear height in the cavity not obstructed by cross studs. (Figure 9)

In horizontal orientation, it is necessary to cut through 2 vertical studs and therefore cross studs should be fitted above and below the speaker to support the wall. A clear vertical spacing of 38cm (15 in) between the cross studs is needed to provide the necessary volume for the speaker. (Figure 10)

Keep the whole of the cavity available to the speaker clear of services or ducting that may be induced to rattle.

Screw the 6 brackets to the front of the PMK frame using the

In horizontal orientation, use the 4 anchor positions along the short sides and the 2 central ones along the long side. (Figure 10)

Screw or nail the brackets to the wall studs, using a spirit level to ensure the frame is properly square.

2

New drywall construction with back box

Stage 1 – fitting the back box

Ensure the wall studding is properly prepared so that there is sufficient clearance for the back box and its cable entry gland. The speaker baffle may be positioned either in the centre or to one end of the back box, allowing greater flexibility in positioning the back box around the desired speaker position. (Figure 16)

In vertical orientation, the back box fits between two adjacent studs if on standard 40cm (16 in) spacing. (Figure 13)

In horizontal orientation, it is necessary to cut through 3 vertical studs and therefore cross studs should be fitted above and below the back box to support the wall. (Figure 14)

Attach the 4 brackets to the back box as required to fix to the wall studs. Use 4 M6 machine screws and washers per bracket. If the brackets are fitted to a short side, they overlap and only 6 screws are required to fix 2 brackets. Do not tighten the screws fully at this stage to allow the brackets to slide. (Figures 13, 14 & 15)

Knock out one of the circular cable entry discs in the back box and fit the cable entry gland. If using vertical orientation, knock out the disc in the short side at the open end. If using horizontal orientation, knock out one of the discs in a long side, preferably one nearest the open end.

New solid wall construction with back box

Stage 1 – building in the back box

The back box is used to define the working volume of the speaker and should be built in to the brick or block work in a similar manner to a window frame. The brackets, machine screws and cable entry gland supplied will not be required. Care must be taken to avoid the back box rattling against the wall. It should therefore be wedged in position such as to give a clear gap all round. If it is desired to settle the back box onto the lower course of bricks, use a flexible mastic rather than cement or mortar. The back box is not designed to take the weight of the wall above, so a suitable lintel should be used. (Figure 18)

Before positioning the back box in the wall, knock out one of the circular cable entry discs in the back box and fit the rubber grommet to avoid chafing the cable. The cable entry gland is not required. If the wall is an internal, single thickness wall, it is probably easiest to use one of the cable entries in the back face and run the cable on the reverse side of the wall. (Figure 19) To aid alignment, temporarily fit the front panel to the back box the desired way round, using 2 of the

To prevent debris entering the back box, tape a sheet of polythene or similar over the aperture until all the brickwork is complete.