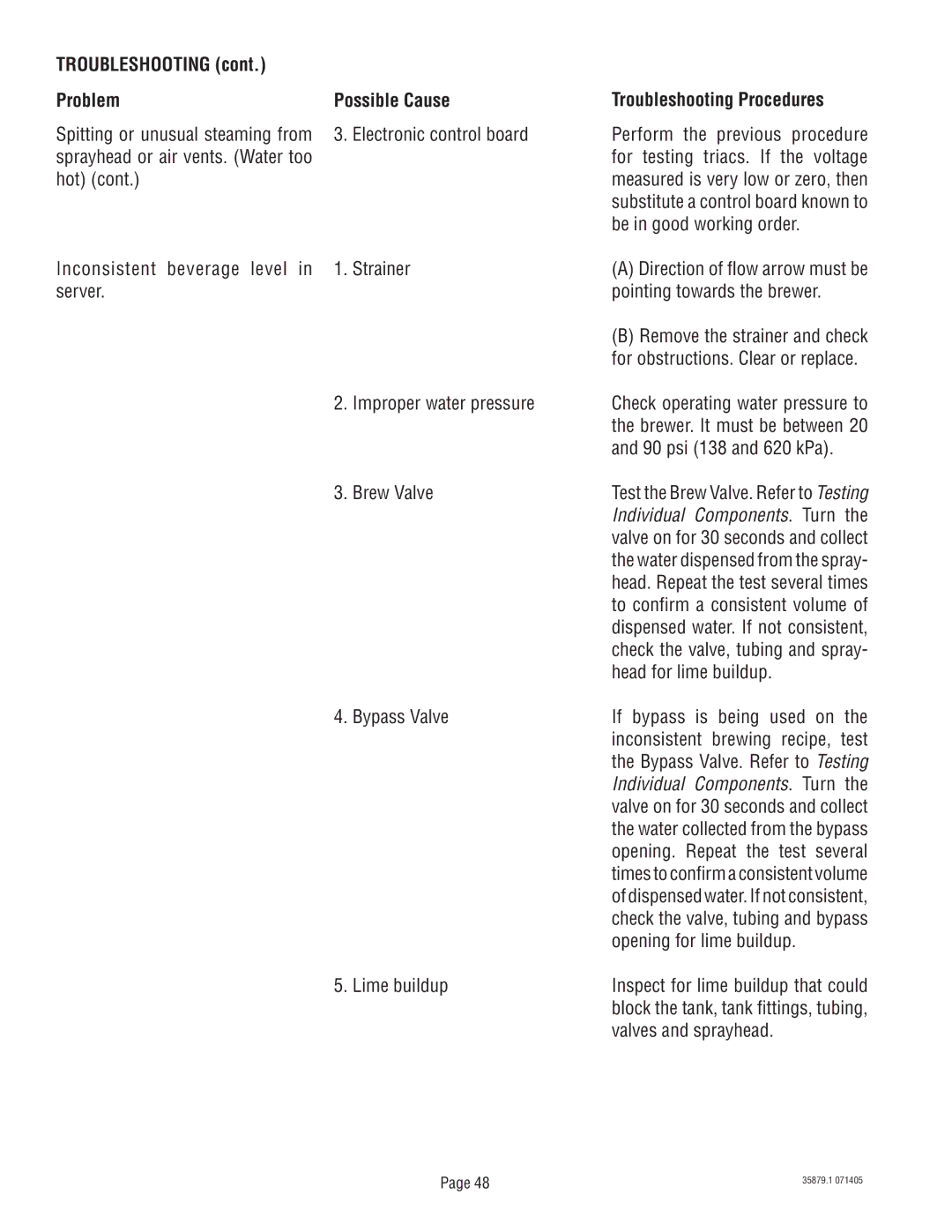

TROUBLESHOOTING (cont.) |

|

|

Problem | Possible Cause | Troubleshooting Procedures |

Spitting or unusual steaming from | 3. Electronic control board | Perform the previous procedure |

sprayhead or air vents. (Water too |

| for testing triacs. If the voltage |

hot) (cont.) |

| measured is very low or zero, then |

|

| substitute a control board known to |

|

| be in good working order. |

Inconsistent beverage level in | 1. Strainer | (A) Direction of flow arrow must be |

server. |

| pointing towards the brewer. |

|

| (B) Remove the strainer and check |

|

| for obstructions. Clear or replace. |

| 2. Improper water pressure | Check operating water pressure to |

|

| the brewer. It must be between 20 |

|

| and 90 psi (138 and 620 kPa). |

| 3. Brew Valve | Test the Brew Valve. Refer to Testing |

|

| Individual Components. Turn the |

|

| valve on for 30 seconds and collect |

|

| the water dispensed from the spray- |

|

| head. Repeat the test several times |

|

| to confirm a consistent volume of |

|

| dispensed water. If not consistent, |

|

| check the valve, tubing and spray- |

|

| head for lime buildup. |

| 4. Bypass Valve | If bypass is being used on the |

|

| inconsistent brewing recipe, test |

|

| the Bypass Valve. Refer to Testing |

|

| Individual Components. Turn the |

|

| valve on for 30 seconds and collect |

|

| the water collected from the bypass |

|

| opening. Repeat the test several |

|

| times to confirm a consistent volume |

|

| of dispensed water. If not consistent, |

|

| check the valve, tubing and bypass |

|

| opening for lime buildup. |

| 5. Lime buildup | Inspect for lime buildup that could |

|

| block the tank, tank fittings, tubing, |

|

| valves and sprayhead. |

Page 48 | 35879.1 071405 |

|