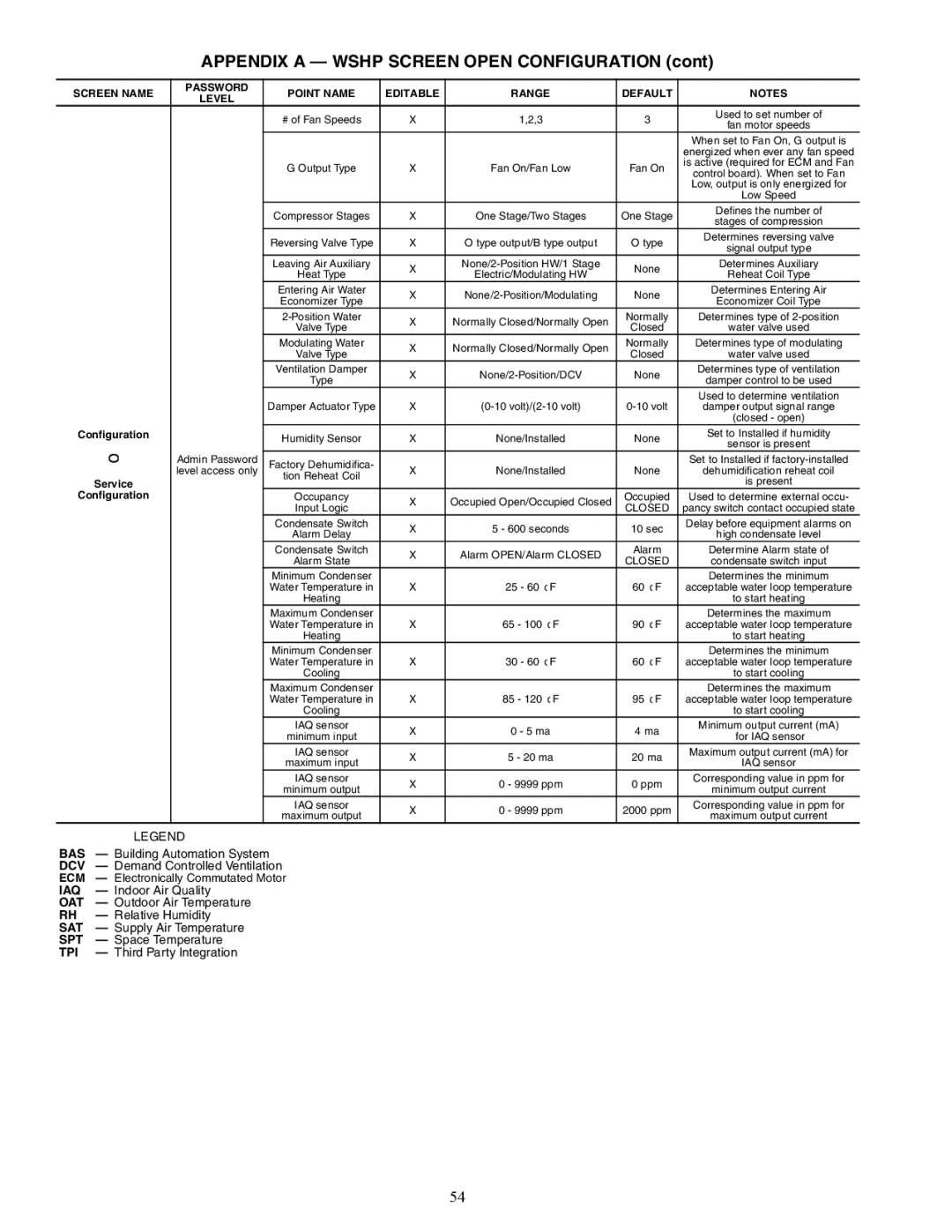

APPENDIX A — WSHP SCREEN OPEN CONFIGURATION (cont)

SCREEN NAME

Configuration

→

Service

Configuration

PASSWORD | POINT NAME | EDITABLE | RANGE | DEFAULT | NOTES | |

LEVEL | ||||||

|

|

|

|

| ||

| # of Fan Speeds | X | 1,2,3 | 3 | Used to set number of | |

| fan motor speeds | |||||

|

|

|

|

| ||

|

|

|

|

| When set to Fan On, G output is | |

|

|

|

|

| energized when ever any fan speed | |

| G Output Type | X | Fan On/Fan Low | Fan On | is active (required for ECM and Fan | |

| control board). When set to Fan | |||||

|

|

|

|

| ||

|

|

|

|

| Low, output is only energized for | |

|

|

|

|

| Low Speed | |

| Compressor Stages | X | One Stage/Two Stages | One Stage | Defines the number of | |

| stages of compression | |||||

|

|

|

|

| ||

| Reversing Valve Type | X | O type output/B type output | O type | Determines reversing valve | |

| signal output type | |||||

|

|

|

|

| ||

| Leaving Air Auxiliary | X | None | Determines Auxiliary | ||

| Heat Type | Electric/Modulating HW | Reheat Coil Type | |||

|

|

| ||||

| Entering Air Water | X | None | Determines Entering Air | ||

| Economizer Type | Economizer Coil Type | ||||

|

|

|

| |||

| X | Normally Closed/Normally Open | Normally | Determines type of | ||

| Valve Type | Closed | water valve used | |||

|

|

| ||||

| Modulating Water | X | Normally Closed/Normally Open | Normally | Determines type of modulating | |

| Valve Type | Closed | water valve used | |||

|

|

| ||||

| Ventilation Damper | X | None | Determines type of ventilation | ||

| Type | damper control to be used | ||||

|

|

|

| |||

|

|

|

|

| Used to determine ventilation | |

| Damper Actuator Type | X | damper output signal range | |||

|

|

|

|

| (closed - open) | |

| Humidity Sensor | X | None/Installed | None | Set to Installed if humidity | |

| sensor is present | |||||

|

|

|

|

| ||

Admin Password | Factory Dehumidifica- | X | None/Installed | None | Set to Installed if | |

level access only | tion Reheat Coil | dehumidification reheat coil | ||||

|

|

|

| is present | ||

|

|

|

|

| ||

| Occupancy | X | Occupied Open/Occupied Closed | Occupied | Used to determine external occu- | |

| Input Logic | CLOSED | pancy switch contact occupied state | |||

|

|

| ||||

| Condensate Switch | X | 5 - 600 seconds | 10 sec | Delay before equipment alarms on | |

| Alarm Delay | high condensate level | ||||

|

|

|

| |||

| Condensate Switch | X | Alarm OPEN/Alarm CLOSED | Alarm | Determine Alarm state of | |

| Alarm State | CLOSED | condensate switch input | |||

|

|

| ||||

| Minimum Condenser |

| 25 - 60 ° F | 60 ° F | Determines the minimum | |

| Water Temperature in | X | acceptable water loop temperature | |||

| Heating |

|

|

| to start heating | |

| Maximum Condenser |

| 65 - 100 ° F | 90 ° F | Determines the maximum | |

| Water Temperature in | X | acceptable water loop temperature | |||

| Heating |

|

|

| to start heating | |

| Minimum Condenser |

| 30 - 60 ° F | 60 ° F | Determines the minimum | |

| Water Temperature in | X | acceptable water loop temperature | |||

| Cooling |

|

|

| to start cooling | |

| Maximum Condenser |

| 85 - 120 ° F | 95 ° F | Determines the maximum | |

| Water Temperature in | X | acceptable water loop temperature | |||

| Cooling |

|

|

| to start cooling | |

| IAQ sensor | X | 0 - 5 ma | 4 ma | Minimum output current (mA) | |

| minimum input | for IAQ sensor | ||||

|

|

|

| |||

| IAQ sensor | X | 5 - 20 ma | 20 ma | Maximum output current (mA) for | |

| maximum input | IAQ sensor | ||||

|

|

|

| |||

| IAQ sensor | X | 0 - 9999 ppm | 0 ppm | Corresponding value in ppm for | |

| minimum output | minimum output current | ||||

|

|

|

| |||

| IAQ sensor | X | 0 - 9999 ppm | 2000 ppm | Corresponding value in ppm for | |

| maximum output | maximum output current | ||||

|

|

|

|

| LEGEND |

BAS | — Building Automation System |

DCV | — Demand Controlled Ventilation |

ECM | — Electronically Commutated Motor |

IAQ | — Indoor Air Quality |

OAT | — Outdoor Air Temperature |

RH | — Relative Humidity |

SAT | — Supply Air Temperature |

SPT | — Space Temperature |

TPI | — Third Party Integration |

54