LINE CONTACT ONLY PERMISSIBLE BETWEEN |

|

LINES FORMED BY INTERSECTIONS OF |

|

THE TOP AND TWO SIDES OF THE FURNACE |

|

JACKET AND BUILDING JOISTS, |

|

STUDS, OR FRAMING. | 17 3/4″ (451mm)OVERALL |

| 4 3/4″ (121mm) UNDER DOOR |

| 1″ (25mm) UNDER FURNACE |

EQUIPMENT MANUAL

SEDIMENT

TRAP

GAS |

|

| EXTEND OUT 12″ (305mm) | ||||

ENTRY |

|

| VENT | FROM FACE OF DOOR | |||

|

|

|

|

|

| ||

|

| IN | * | (15 | 2mm) |

|

|

| 6″ M |

|

|

| |||

|

|

|

|

| |||

|

|

|

| ||||

|

|

|

| * WHEN USED WITH | |||

|

|

|

|

| |||

|

|

|

|

| MIN WORK AREA | ||

|

|

|

|

|

|

| SINGLE WALL VENT |

|

|

|

|

|

|

| CONNECTIONS |

17 3/4″ (451mm) |

|

|

|

|

|

| |

SHEET |

|

|

|

|

|

|

|

METAL | (559mm) |

|

|

|

|

|

|

22″ |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

UNION

A03177

58CT

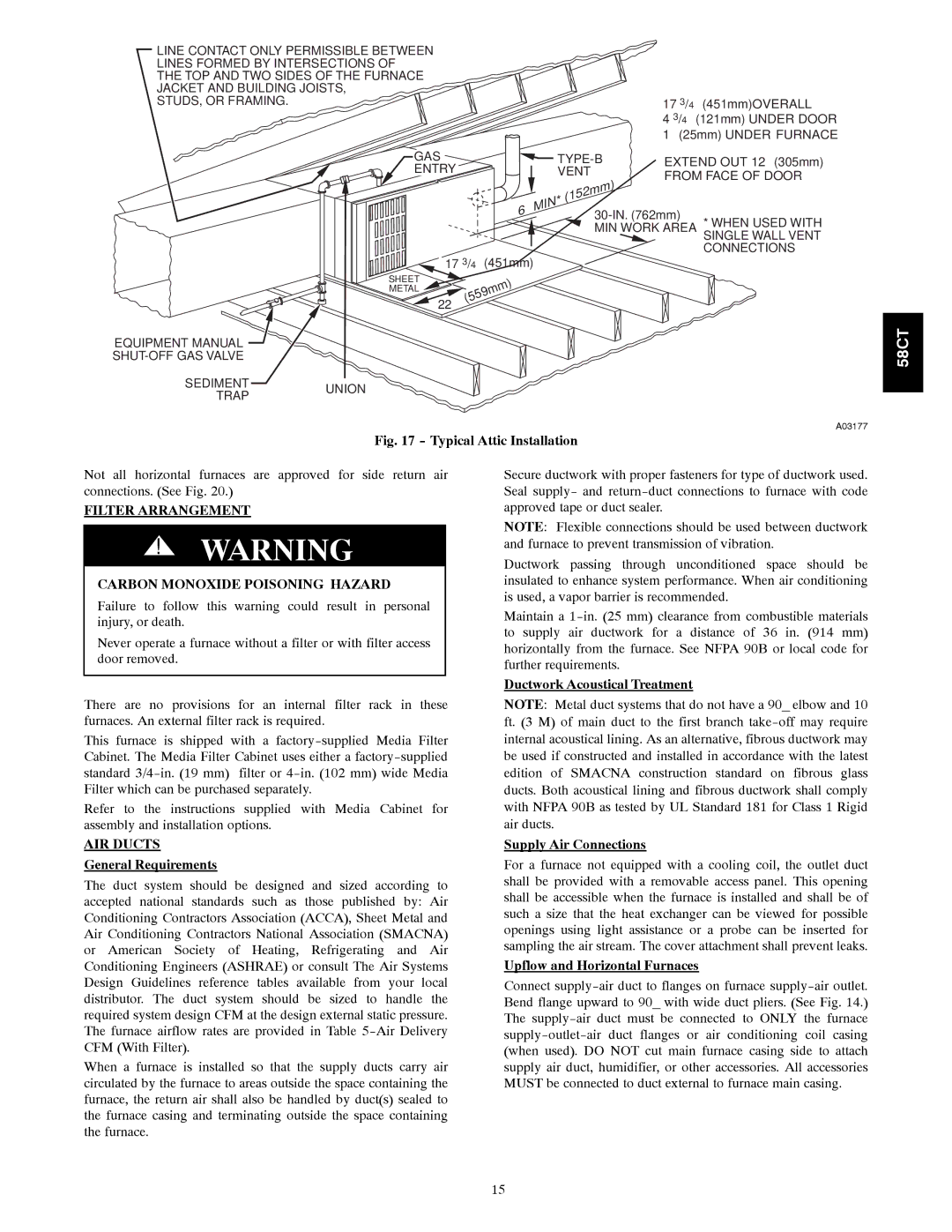

Fig. 17 - Typical Attic Installation

Not all horizontal furnaces are approved for side return air connections. (See Fig. 20.)

FILTER ARRANGEMENT

!WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury, or death.

Never operate a furnace without a filter or with filter access door removed.

There are no provisions for an internal filter rack in these furnaces. An external filter rack is required.

This furnace is shipped with a

Refer to the instructions supplied with Media Cabinet for assembly and installation options.

AIR DUCTS

General Requirements

The duct system should be designed and sized according to accepted national standards such as those published by: Air Conditioning Contractors Association (ACCA), Sheet Metal and Air Conditioning Contractors National Association (SMACNA) or American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE) or consult The Air Systems Design Guidelines reference tables available from your local distributor. The duct system should be sized to handle the required system design CFM at the design external static pressure. The furnace airflow rates are provided in Table

When a furnace is installed so that the supply ducts carry air circulated by the furnace to areas outside the space containing the furnace, the return air shall also be handled by duct(s) sealed to the furnace casing and terminating outside the space containing the furnace.

Secure ductwork with proper fasteners for type of ductwork used. Seal supply- and

NOTE: Flexible connections should be used between ductwork and furnace to prevent transmission of vibration.

Ductwork passing through unconditioned space should be insulated to enhance system performance. When air conditioning is used, a vapor barrier is recommended.

Maintain a

Ductwork Acoustical Treatment

NOTE: Metal duct systems that do not have a 90_ elbow and 10 ft. (3 M) of main duct to the first branch

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct shall be provided with a removable access panel. This opening shall be accessible when the furnace is installed and shall be of such a size that the heat exchanger can be viewed for possible openings using light assistance or a probe can be inserted for sampling the air stream. The cover attachment shall prevent leaks.

Upflow and Horizontal Furnaces

Connect

15