b.Run for 3 minutes in

c.Measure time (in sec) for gas meter to complete 1 revolu- tion and note reading. The 2 or 5 cubic feet dial provides a more accurate measurement of gas flow.

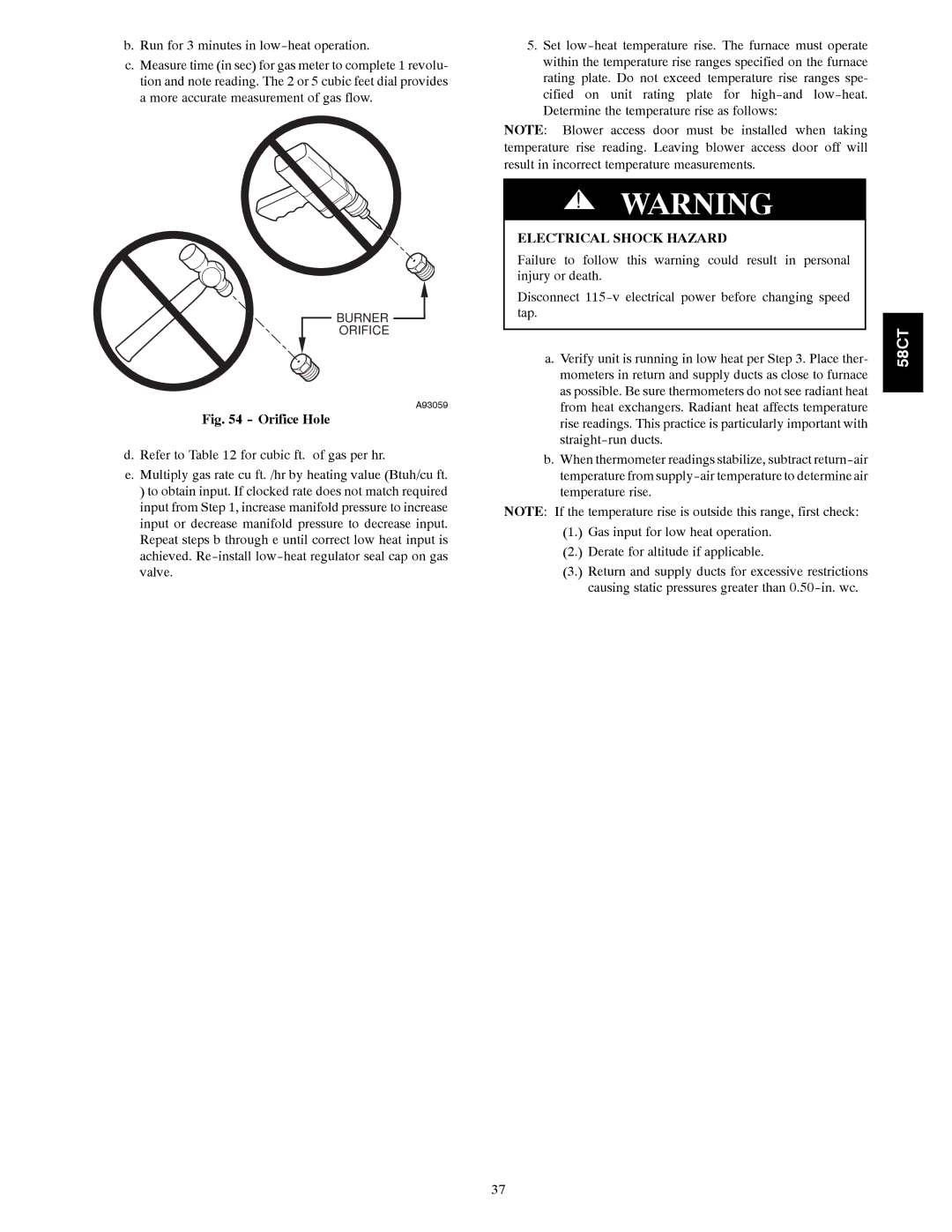

BURNER ![]()

ORIFICE

A93059

Fig. 54 - Orifice Hole

d.Refer to Table 12 for cubic ft. of gas per hr.

e.Multiply gas rate cu ft. /hr by heating value (Btuh/cu ft. ) to obtain input. If clocked rate does not match required input from Step 1, increase manifold pressure to increase input or decrease manifold pressure to decrease input. Repeat steps b through e until correct low heat input is achieved.

5.Set

NOTE: Blower access door must be installed when taking temperature rise reading. Leaving blower access door off will result in incorrect temperature measurements.

!WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Disconnect

a.Verify unit is running in low heat per Step 3. Place ther- mometers in return and supply ducts as close to furnace as possible. Be sure thermometers do not see radiant heat from heat exchangers. Radiant heat affects temperature rise readings. This practice is particularly important with

b.When thermometer readings stabilize, subtract

NOTE: If the temperature rise is outside this range, first check: (1.) Gas input for low heat operation.

(2.) Derate for altitude if applicable.

(3.) Return and supply ducts for excessive restrictions causing static pressures greater than

58CT

37