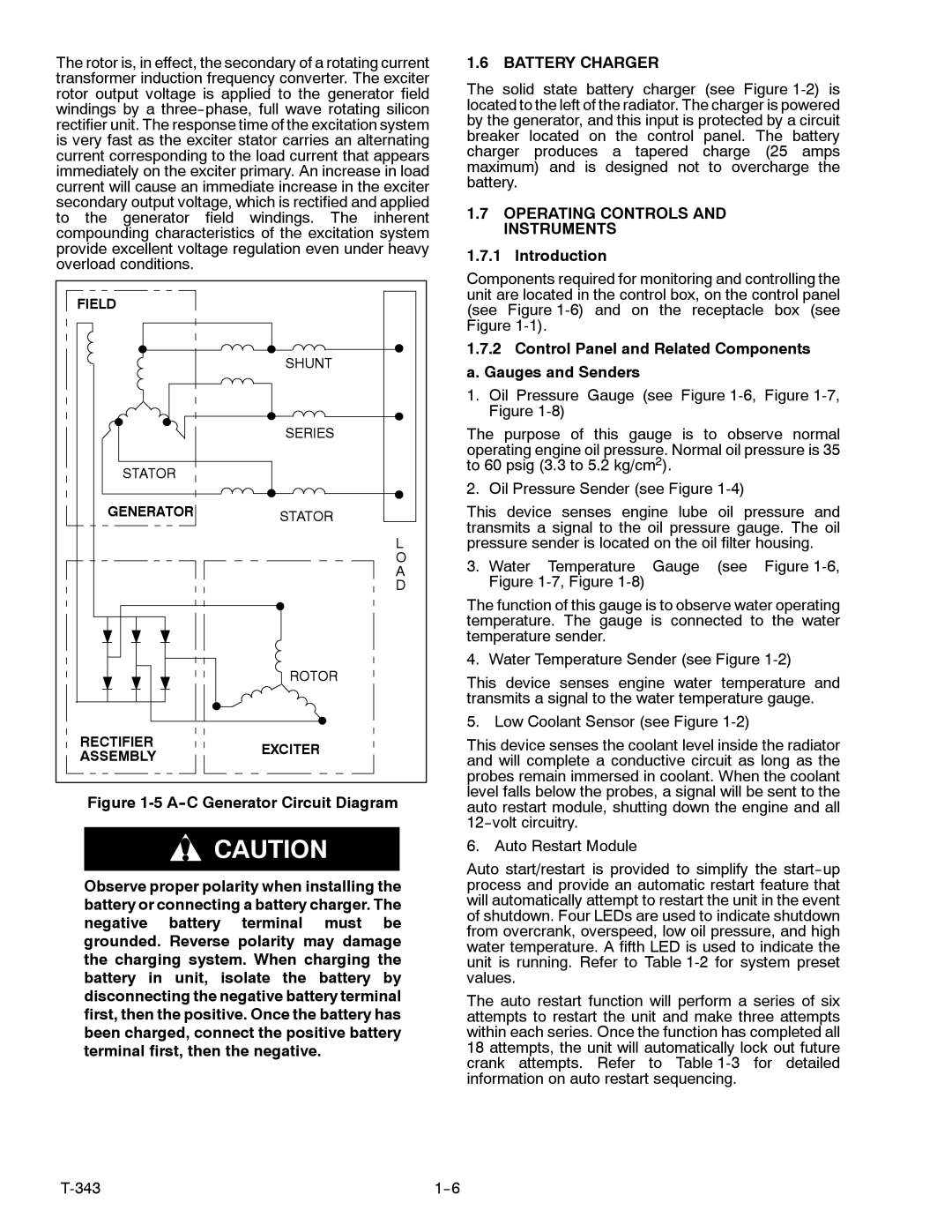

The rotor is, in effect, the secondary of a rotating current transformer induction frequency converter. The exciter rotor output voltage is applied to the generator field windings by a

FIELD |

| |

| SHUNT | |

| SERIES | |

STATOR |

| |

GENERATOR | STATOR | |

| ||

| L | |

| O | |

| A | |

| D | |

| ROTOR | |

RECTIFIER | EXCITER | |

ASSEMBLY | ||

| ||

Figure | ||

![]() CAUTION

CAUTION

Observe proper polarity when installing the battery or connecting a battery charger. The negative battery terminal must be grounded. Reverse polarity may damage the charging system. When charging the battery in unit, isolate the battery by disconnecting the negative battery terminal first, then the positive. Once the battery has been charged, connect the positive battery terminal first, then the negative.

1.6 BATTERY CHARGER

The solid state battery charger (see Figure

1.7OPERATING CONTROLS AND INSTRUMENTS

1.7.1 Introduction

Components required for monitoring and controlling the unit are located in the control box, on the control panel (see Figure

1.7.2Control Panel and Related Components a. Gauges and Senders

1.Oil Pressure Gauge (see Figure

The purpose of this gauge is to observe normal operating engine oil pressure. Normal oil pressure is 35 to 60 psig (3.3 to 5.2 kg/cm2).

2. Oil Pressure Sender (see Figure

This device senses engine lube oil pressure and transmits a signal to the oil pressure gauge. The oil pressure sender is located on the oil filter housing.

3.Water Temperature Gauge (see Figure

The function of this gauge is to observe water operating temperature. The gauge is connected to the water temperature sender.

4. Water Temperature Sender (see Figure

This device senses engine water temperature and transmits a signal to the water temperature gauge.

5. Low Coolant Sensor (see Figure

This device senses the coolant level inside the radiator and will complete a conductive circuit as long as the probes remain immersed in coolant. When the coolant level falls below the probes, a signal will be sent to the auto restart module, shutting down the engine and all

6. Auto Restart Module

Auto start/restart is provided to simplify the

The auto restart function will perform a series of six attempts to restart the unit and make three attempts within each series. Once the function has completed all 18 attempts, the unit will automatically lock out future crank attempts. Refer to Table

|