T-343

Table

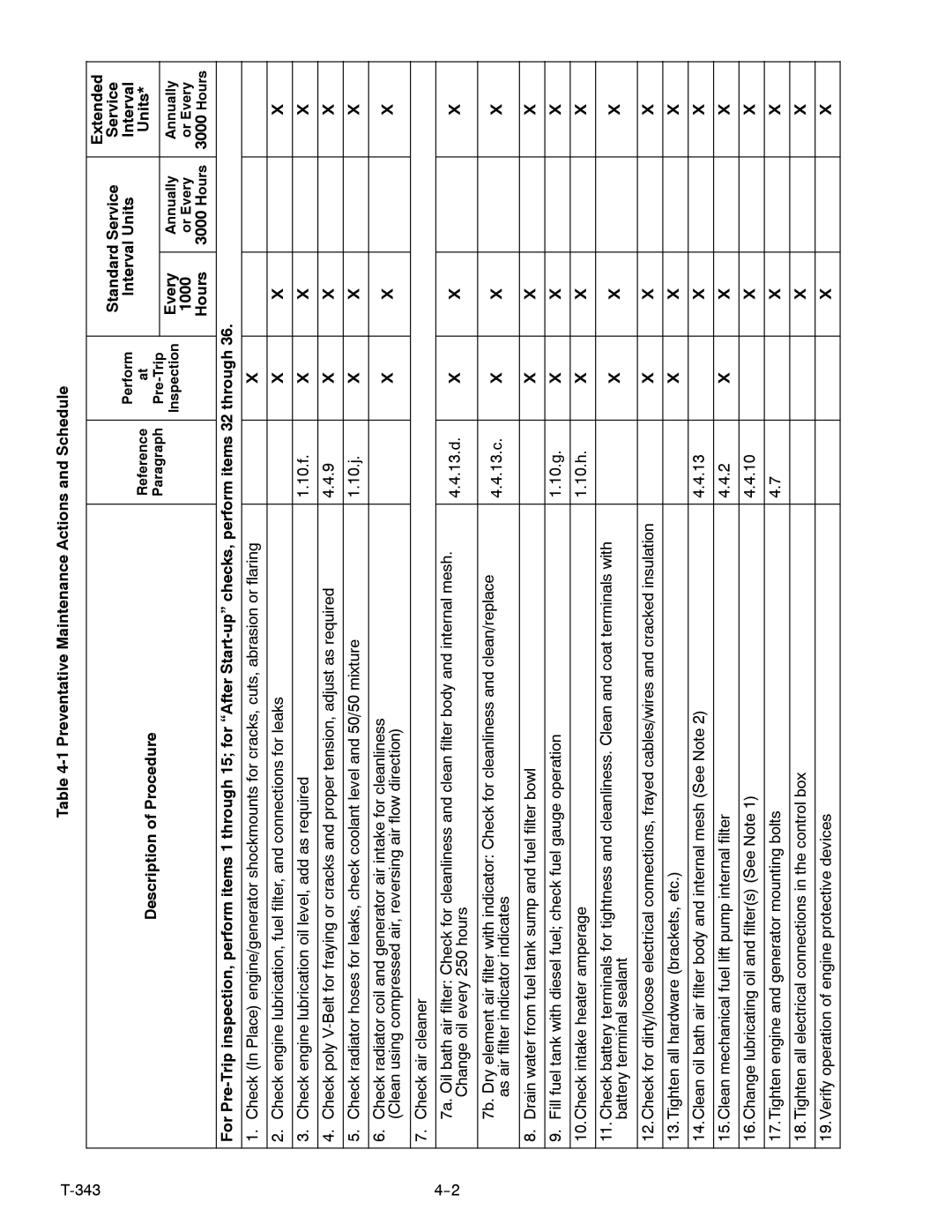

|

|

|

|

|

|

| Extended |

|

|

|

|

| Standard Service | Service | |

|

|

| Perform |

| Interval Units | Interval | |

| Description of Procedure | Reference | at |

|

|

| Units* |

| Paragraph |

|

|

|

| ||

|

|

|

|

|

| ||

|

|

| Inspection |

| Every | Annually | Annually |

|

|

|

|

| 1000 | or Every | or Every |

|

|

|

|

| Hours | 3000 Hours | 3000 Hours |

|

|

|

|

|

|

| |

For |

|

|

| ||||

|

|

|

|

|

|

|

|

1. | Check (In Place) engine/generator shockmounts for cracks, cuts, abrasion or flaring |

| X |

|

|

|

|

|

|

|

|

|

|

|

|

2. | Check engine lubrication, fuel filter, and connections for leaks |

| X |

| X |

| X |

|

|

|

|

|

|

|

|

3. | Check engine lubrication oil level, add as required | 1.10.f. | X |

| X |

| X |

|

|

|

|

|

|

|

|

4. | Check poly | 4.4.9 | X |

| X |

| X |

|

|

|

|

|

|

|

|

5. | Check radiator hoses for leaks, check coolant level and 50/50 mixture | 1.10.j. | X |

| X |

| X |

|

|

|

|

|

|

|

|

6. | Check radiator coil and generator air intake for cleanliness |

| X |

| X |

| X |

| (Clean using compressed air, reversing air flow direction) |

|

|

| |||

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

7. | Check air cleaner |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 7a. Oil bath air filter: Check for cleanliness and clean filter body and internal mesh. | 4.4.13.d. | X |

| X |

| X |

| Change oil every 250 hours |

|

| ||||

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| 7b. Dry element air filter with indicator: Check for cleanliness and clean/replace | 4.4.13.c. | X |

| X |

| X |

| as air filter indicator indicates |

|

| ||||

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

8. | Drain water from fuel tank sump and fuel filter bowl |

| X |

| X |

| X |

|

|

|

|

|

|

|

|

9. | Fill fuel tank with diesel fuel; check fuel gauge operation | 1.10.g. | X |

| X |

| X |

|

|

|

|

|

|

| |

10.Check intake heater amperage | 1.10.h. | X |

| X |

| X | |

|

|

|

|

|

|

| |

11. Check battery terminals for tightness and cleanliness. Clean and coat terminals with |

| X |

| X |

| X | |

| battery terminal sealant |

|

|

| |||

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

12.Check for dirty/loose electrical connections, frayed cables/wires and cracked insulation |

| X |

| X |

| X | |

|

|

|

|

|

|

| |

13.Tighten all hardware (brackets, etc.) |

| X |

| X |

| X | |

|

|

|

|

|

|

| |

14.Clean oil bath air filter body and internal mesh (See Note 2) | 4.4.13 |

|

| X |

| X | |

|

|

|

|

|

|

| |

15.Clean mechanical fuel lift pump internal filter | 4.4.2 | X |

| X |

| X | |

|

|

|

|

|

|

| |

16.Change lubricating oil and filter(s) (See Note 1) | 4.4.10 |

|

| X |

| X | |

|

|

|

|

|

|

| |

17.Tighten engine and generator mounting bolts | 4.7 |

|

| X |

| X | |

|

|

|

|

|

|

| |

18.Tighten all electrical connections in the control box |

|

|

| X |

| X | |

|

|

|

|

|

|

| |

19.Verify operation of engine protective devices |

|

|

| X |

| X | |

|

|

|

|

|

|

|

|