392.6. Installation. (C) Supports.

The intent of this section is to ensure that the conductor insulation and cable jackets will not be damaged due to stress caused by improper support. Multiconductor 600 volt Type TC cables and 300 volt Type PLTC cables exhibit a high degree of damage resistance when exposed to mechanical abuse at normal temperatures.

During an inspection of industrial installations by the 1973 NEC® Technical Subcommittee on Cable Tray, a test setup was constructed of an 18 inch wide Class 20C aluminum cable tray supported three feet above ground level containing several sizes of multiconductor cables. This installation was continuously struck in the same area with eight pound sledge hammers until the cable tray was severely distorted, the cables however, exhibited only cosmetic damage. When these cables were tested electrically, they checked out as new tray cable. Since that time, significant improvements have been made in cable jacket and conductor insulation materials so that the cables available today are of better quality than the 1973 test cables. Although tray cables are capable of taking a great deal of abuse without any problems, cable tray installations must be designed by taking appropriate measures to ensure that the tray cables will not be subjected to mechanical damage.

high winds, the light duty clips are not capable of restraining the covers. Outdoor cover installations should be overlapped at expansion joint locations to eliminate cover buckling. Covers which fly off the cable tray create a serious hazard to personnel, as was the case at a Texas gulf coast chemical plant where operators would not leave their control room because hurricane force winds had stripped many light gauge stainless steel covers off a large cable tray system. These sharp edged metal covers were flying though the air all during the high wind period, posing a serious threat to the worker's safety.

|

|

|

|

|

| Solid |

|

| Solid Flanged |

|

|

|

|

|

|

|

|

|

|

|

|

| Peaked Flanged |

|

|

| Ventilated Flanged |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

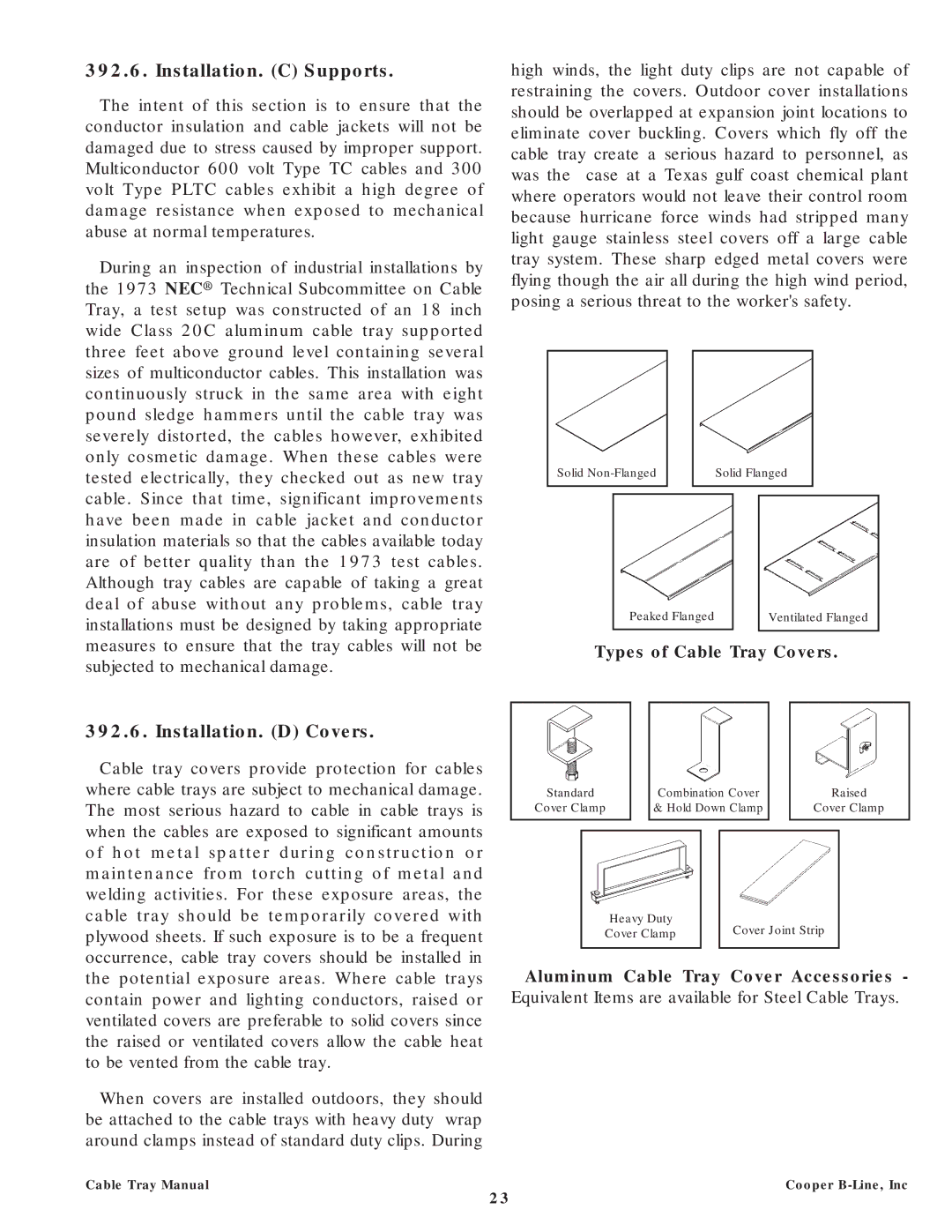

Types of Cable Tray Covers.

392.6. Installation. (D) Covers.

Cable tray covers provide protection for cables where cable trays are subject to mechanical damage. The most serious hazard to cable in cable trays is when the cables are exposed to significant amounts of hot metal spatter during construction or maintenance from torch cutting of metal and welding activities. For these exposure areas, the cable tray should be temporarily covered with plywood sheets. If such exposure is to be a frequent occurrence, cable tray covers should be installed in the potential exposure areas. Where cable trays contain power and lighting conductors, raised or ventilated covers are preferable to solid covers since the raised or ventilated covers allow the cable heat to be vented from the cable tray.

When covers are installed outdoors, they should be attached to the cable trays with heavy duty wrap around clamps instead of standard duty clips. During

|

|

|

|

|

|

|

|

|

| Standard |

|

| Combination Cover |

|

| Raised |

|

| Cover Clamp |

|

| & Hold Down Clamp |

|

| Cover Clamp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heavy Duty | Cover Joint Strip |

Cover Clamp |

Aluminum Cable Tray Cover Accessories - Equivalent Items are available for Steel Cable Trays.

Cable Tray Manual | Cooper |

23