Metal Temperature At Time Of Installation (F° or C°)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

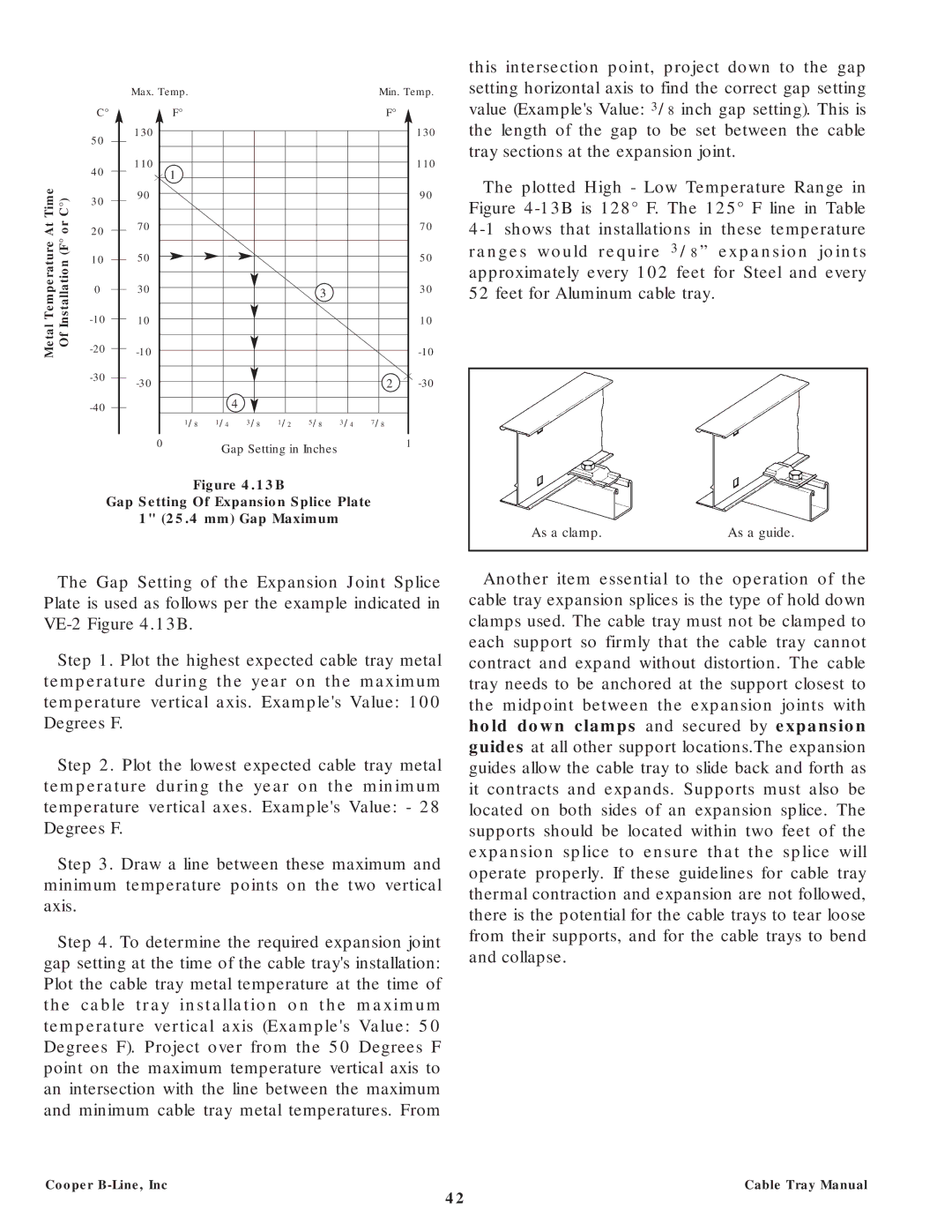

| this intersection point, project down to the gap | |||||||

|

|

| Max. Temp. |

| Min. Temp. | setting horizontal axis to find the correct gap setting | ||||||||||||||||||

C° |

|

|

|

| F° |

| F° | value (Example's Value: 3/8 inch gap setting). This is | ||||||||||||||||

50 |

|

| 130 |

|

|

|

|

|

|

|

|

|

|

|

| 130 | the length of the gap to be set between the cable | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

|

| 110 |

|

|

|

|

|

|

|

|

|

|

|

| 110 | tray sections at the expansion joint. | ||||||||

40 |

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

| 1 |

|

|

|

|

|

|

|

|

| The plotted High - Low Temperature Range in | |||||||||||

| 90 |

|

|

|

|

|

|

|

|

|

|

| 90 | |||||||||||

30 |

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| Figure | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

20 |

|

| 70 |

|

|

|

|

|

|

|

|

|

|

|

| 70 | ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

10 |

|

| 50 |

|

|

|

|

|

|

|

|

|

|

|

| 50 | ranges would require 3/8” | expansion joints | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| approximately every 102 feet for Steel and every | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

0 |

|

| 30 |

|

|

|

|

|

|

|

|

|

|

|

| 30 | 52 feet for Aluminum cable tray. |

|

|

| ||||

|

|

|

|

|

|

|

| 3 |

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

| 10 |

|

|

|

|

|

|

|

|

|

|

|

| 10 |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2 |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| 1/8 1/4 3/8 1/2 5/8 3/4 | 7/8 |

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

| 0 |

| Gap Setting in Inches | 1 |

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

| Figure 4.13B |

|

|

|

|

|

|

|

|

|

|

| ||||||

Gap Setting Of Expansion Splice Plate |

|

|

|

|

|

|

|

| ||||||||||||||||

|

|

| 1" (25.4 mm) Gap Maximum |

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| As a clamp. |

|

|

| As a guide. |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Gap Setting of the Expansion Joint Splice Plate is used as follows per the example indicated in

Step 1. Plot the highest expected cable tray metal temperature during the year on the maximum temperature vertical axis. Example's Value: 100 Degrees F.

Step 2. Plot the lowest expected cable tray metal temperature during the year on the minimum temperature vertical axes. Example's Value: - 28 Degrees F.

Step 3. Draw a line between these maximum and minimum temperature points on the two vertical axis.

Step 4. To determine the required expansion joint gap setting at the time of the cable tray's installation: Plot the cable tray metal temperature at the time of the cable tray installation on the maximum temperature vertical axis (Example's Value: 50 Degrees F). Project over from the 50 Degrees F point on the maximum temperature vertical axis to an intersection with the line between the maximum and minimum cable tray metal temperatures. From

Another item essential to the operation of the cable tray expansion splices is the type of hold down clamps used. The cable tray must not be clamped to each support so firmly that the cable tray cannot contract and expand without distortion. The cable tray needs to be anchored at the support closest to the midpoint between the expansion joints with hold down clamps and secured by expansion guides at all other support locations.The expansion guides allow the cable tray to slide back and forth as it contracts and expands. Supports must also be located on both sides of an expansion splice. The supports should be located within two feet of the expansion splice to ensure that the splice will operate properly. If these guidelines for cable tray thermal contraction and expansion are not followed, there is the potential for the cable trays to tear loose from their supports, and for the cable trays to bend and collapse.

Cooper | Cable Tray Manual |

42