FENCE LUBRICATION

1.Apply paste wax to fence and guide tube sliding sur- faces weekly.

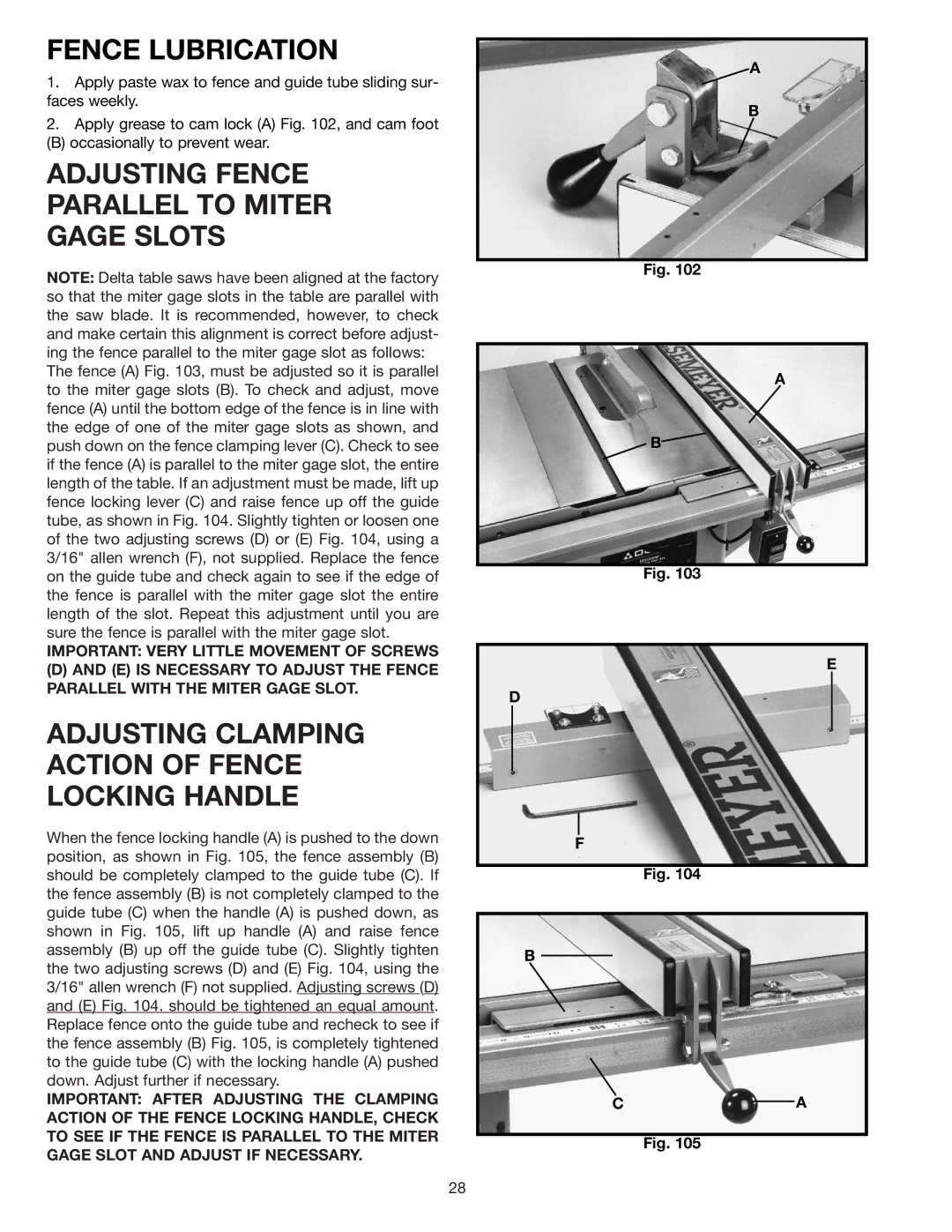

2.Apply grease to cam lock (A) Fig. 102, and cam foot

(B) occasionally to prevent wear.

ADJUSTING FENCE

PARALLEL TO MITER

GAGE SLOTS

NOTE: Delta table saws have been aligned at the factory so that the miter gage slots in the table are parallel with the saw blade. It is recommended, however, to check and make certain this alignment is correct before adjust- ing the fence parallel to the miter gage slot as follows:

The fence (A) Fig. 103, must be adjusted so it is parallel to the miter gage slots (B). To check and adjust, move fence (A) until the bottom edge of the fence is in line with the edge of one of the miter gage slots as shown, and push down on the fence clamping lever (C). Check to see if the fence (A) is parallel to the miter gage slot, the entire length of the table. If an adjustment must be made, lift up fence locking lever (C) and raise fence up off the guide tube, as shown in Fig. 104. Slightly tighten or loosen one of the two adjusting screws (D) or (E) Fig. 104, using a 3/16" alIen wrench (F), not supplied. Replace the fence on the guide tube and check again to see if the edge of the fence is parallel with the miter gage slot the entire length of the slot. Repeat this adjustment until you are sure the fence is parallel with the miter gage slot.

IMPORTANT: VERY LITTLE MOVEMENT OF SCREWS

(D)AND (E) IS NECESSARY TO ADJUST THE FENCE PARALLEL WITH THE MITER GAGE SLOT.

ADJUSTING CLAMPING ACTION OF FENCE LOCKING HANDLE

When the fence locking handle (A) is pushed to the down position, as shown in Fig. 105, the fence assembly (B) should be completely clamped to the guide tube (C). If the fence assembly (B) is not completely clamped to the guide tube (C) when the handle (A) is pushed down, as shown in Fig. 105, lift up handle (A) and raise fence assembly (B) up off the guide tube (C). Slightly tighten the two adjusting screws (D) and (E) Fig. 104, using the 3/16" allen wrench (F) not supplied. Adjusting screws (D) and (E) Fig. 104. should be tightened an equal amount. Replace fence onto the guide tube and recheck to see if the fence assembly (B) Fig. 105, is completely tightened to the guide tube (C) with the locking handle (A) pushed down. Adjust further if necessary.

IMPORTANT: AFTER ADJUSTING THE CLAMPING ACTION OF THE FENCE LOCKING HANDLE, CHECK TO SEE IF THE FENCE IS PARALLEL TO THE MITER GAGE SLOT AND ADJUST IF NECESSARY.

A

B

Fig. 102

A

B![]()

Fig. 103

E

D

F

Fig. 104

B

CA

Fig. 105

28