Auto

parameters are displayed in ![]() ,

, ![]() ,

, ![]() ,

, ![]() and

and ![]() , of which their content can be revised by the user.

, of which their content can be revised by the user.

¾Automatic

Set parameter ![]() to 0 (PID 0, the first set) in【Regulation Mode】, set the required SV value (e.g. 100 degree), set parameter

to 0 (PID 0, the first set) in【Regulation Mode】, set the required SV value (e.g. 100 degree), set parameter ![]() as ON; on completion of auto

as ON; on completion of auto ![]() =100,

=100, ![]() ,

, ![]() ,

, ![]() and

and ![]() automatically, their content can be revised by the user.

automatically, their content can be revised by the user.

Set parameter ![]() to 1 (PID 1, the second set), set the required SV value (e.g. 150 degree), set parameter

to 1 (PID 1, the second set), set the required SV value (e.g. 150 degree), set parameter ![]() as ON; on

as ON; on

completion of auto ![]() =150,

=150, ![]() ,

, ![]() ,

, ![]() and

and ![]() automatically.

automatically.

Set parameter ![]() to AUTO, System will verify on its own whether the current SV value is closer to parameter

to AUTO, System will verify on its own whether the current SV value is closer to parameter ![]() or

or ![]() ,

,

and load the corresponding PID set automatically. E.g., if SV=110, system will load ![]() parameters. If SV=140, system will load

parameters. If SV=140, system will load ![]() parameters.

parameters.

If more SV groups are required, PID2~PID5 can be set up with the same sequence as described above.

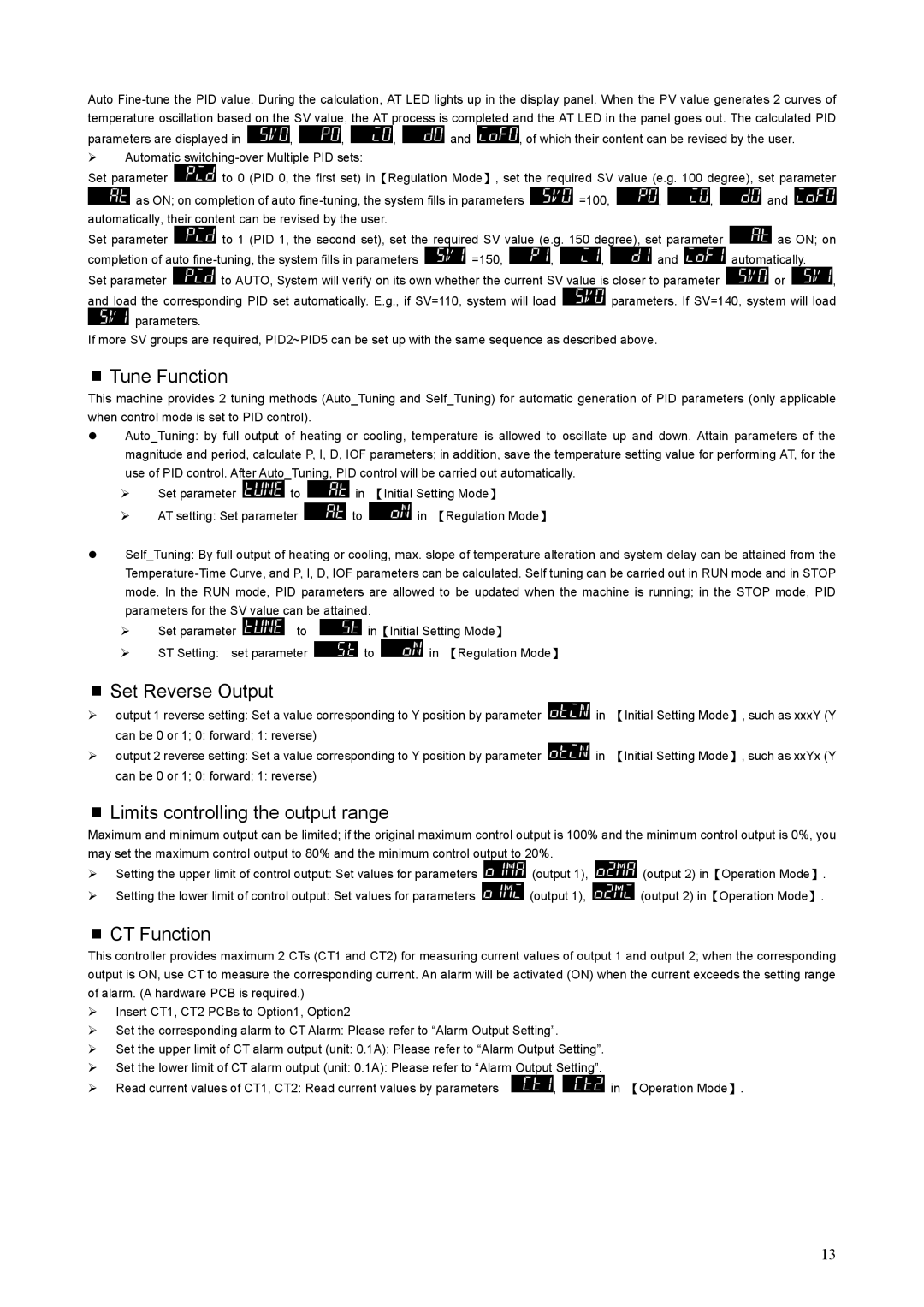

Tune Function

This machine provides 2 tuning methods (Auto_Tuning and Self_Tuning) for automatic generation of PID parameters (only applicable when control mode is set to PID control).

zAuto_Tuning: by full output of heating or cooling, temperature is allowed to oscillate up and down. Attain parameters of the magnitude and period, calculate P, I, D, IOF parameters; in addition, save the temperature setting value for performing AT, for the use of PID control. After Auto_Tuning, PID control will be carried out automatically.

¾Set parameter ![]() to

to ![]() in 【Initial Setting Mode】

in 【Initial Setting Mode】

¾AT setting: Set parameter ![]() to

to ![]() in 【Regulation Mode】

in 【Regulation Mode】

zSelf_Tuning: By full output of heating or cooling, max. slope of temperature alteration and system delay can be attained from the

¾Set parameter ![]() to

to ![]() in【Initial Setting Mode】

in【Initial Setting Mode】

¾ST Setting: set parameter ![]() to

to ![]() in 【Regulation Mode】

in 【Regulation Mode】

Set Reverse Output

¾output 1 reverse setting: Set a value corresponding to Y position by parameter ![]() in 【Initial Setting Mode】, such as xxxY (Y

in 【Initial Setting Mode】, such as xxxY (Y

can be 0 or 1; 0: forward; 1: reverse)

¾output 2 reverse setting: Set a value corresponding to Y position by parameter ![]() in 【Initial Setting Mode】, such as xxYx (Y

in 【Initial Setting Mode】, such as xxYx (Y

can be 0 or 1; 0: forward; 1: reverse)

Limits controlling the output range

Maximum and minimum output can be limited; if the original maximum control output is 100% and the minimum control output is 0%, you may set the maximum control output to 80% and the minimum control output to 20%.

¾Setting the upper limit of control output: Set values for parameters ![]() (output 1),

(output 1), ![]() (output 2) in【Operation Mode】.

(output 2) in【Operation Mode】.

¾Setting the lower limit of control output: Set values for parameters ![]() (output 1),

(output 1), ![]() (output 2) in【Operation Mode】.

(output 2) in【Operation Mode】.

CT Function

This controller provides maximum 2 CTs (CT1 and CT2) for measuring current values of output 1 and output 2; when the corresponding output is ON, use CT to measure the corresponding current. An alarm will be activated (ON) when the current exceeds the setting range of alarm. (A hardware PCB is required.)

¾Insert CT1, CT2 PCBs to Option1, Option2

¾Set the corresponding alarm to CT Alarm: Please refer to “Alarm Output Setting”.

¾Set the upper limit of CT alarm output (unit: 0.1A): Please refer to “Alarm Output Setting”.

¾Set the lower limit of CT alarm output (unit: 0.1A): Please refer to “Alarm Output Setting”.

¾ Read current values of CT1, CT2: Read current values by parameters | , | in 【Operation Mode】. |

13