MODEL | SECTION 10.0 |

| TROUBLESHOOTING |

10.3 TROUBLESHOOTING WHEN NO FAULT MESSAGE IS SHOWING - TEMPERATURE

10.3.1 Temperature measured by standard was more than 1°C different from analyzer.

A.Is the standard thermometer, RTD, or thermistor accurate? General purpose

B.Is the temperature element in the sensor completely submerged in the liquid?

C.Is the standard temperature sensor submerged to the correct level?

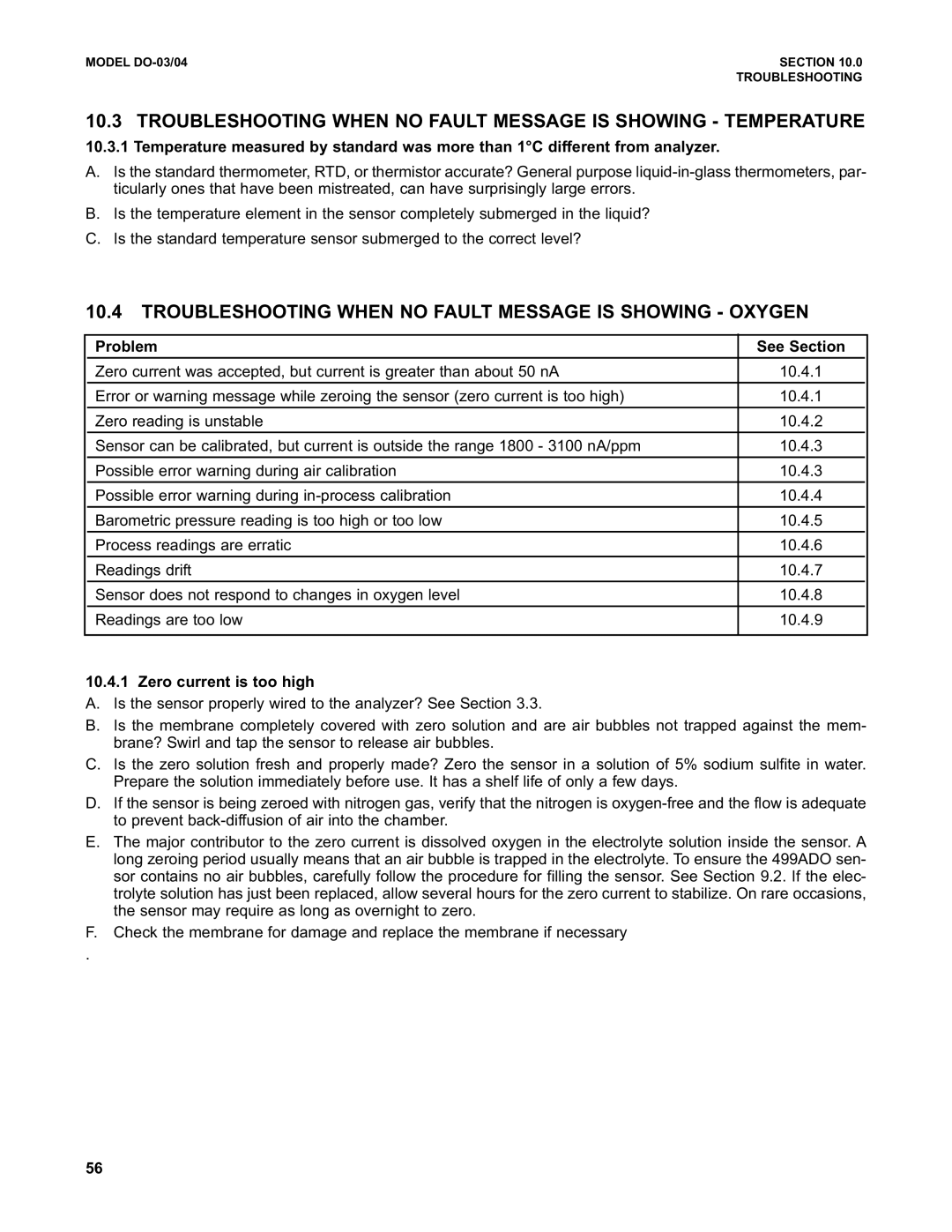

10.4TROUBLESHOOTING WHEN NO FAULT MESSAGE IS SHOWING - OXYGEN

| Problem | See Section |

|

|

|

|

|

| Zero current was accepted, but current is greater than about 50 nA | 10.4.1 |

|

| Error or warning message while zeroing the sensor (zero current is too high) | 10.4.1 |

|

|

|

|

|

| Zero reading is unstable | 10.4.2 |

|

|

|

|

|

| Sensor can be calibrated, but current is outside the range 1800 - 3100 nA/ppm | 10.4.3 |

|

|

|

|

|

| Possible error warning during air calibration | 10.4.3 |

|

|

|

|

|

| Possible error warning during | 10.4.4 |

|

|

|

|

|

| Barometric pressure reading is too high or too low | 10.4.5 |

|

|

|

|

|

| Process readings are erratic | 10.4.6 |

|

| Readings drift | 10.4.7 |

|

|

|

|

|

| Sensor does not respond to changes in oxygen level | 10.4.8 |

|

|

|

|

|

| Readings are too low | 10.4.9 |

|

|

|

|

|

10.4.1 Zero current is too high

A.Is the sensor properly wired to the analyzer? See Section 3.3.

B.Is the membrane completely covered with zero solution and are air bubbles not trapped against the mem- brane? Swirl and tap the sensor to release air bubbles.

C.Is the zero solution fresh and properly made? Zero the sensor in a solution of 5% sodium sulfite in water. Prepare the solution immediately before use. It has a shelf life of only a few days.

D.If the sensor is being zeroed with nitrogen gas, verify that the nitrogen is

E.The major contributor to the zero current is dissolved oxygen in the electrolyte solution inside the sensor. A long zeroing period usually means that an air bubble is trapped in the electrolyte. To ensure the 499ADO sen- sor contains no air bubbles, carefully follow the procedure for filling the sensor. See Section 9.2. If the elec- trolyte solution has just been replaced, allow several hours for the zero current to stabilize. On rare occasions, the sensor may require as long as overnight to zero.

F.Check the membrane for damage and replace the membrane if necessary

.

56