methods can increase the rate of anode rod depletion. Once the anode rod is depleted, the tank will start to corrode, eventually developing a leak.

Certain water conditions will cause a reaction between the anode rod and the water. The most common complaint associated with the anode rod is a “rotten egg smell” produced from the presence of hydrogen sulfide gas dissolved in the water. IMPORTANT: Do not remove this rod permanently as it will void any warranties. The parts list includes a special anode rod that can be ordered if water odor or discoloration occurs. NOTE: This rod may reduce but not eliminate water odor problems. The water supply system may require special filtration equipment from a water conditioning company to successfully eliminate all water odor problems.

Artificially softened water is exceedingly corrosive because the process substitutes sodium ions for magnesium and calcium ions. The use of a water softener may decrease the life of the water heater tank.

The anode rod should be removed from the water heater tank every 3 years for inspection. NOTE: artificially softened water requires the anode rod to be inspected annually.

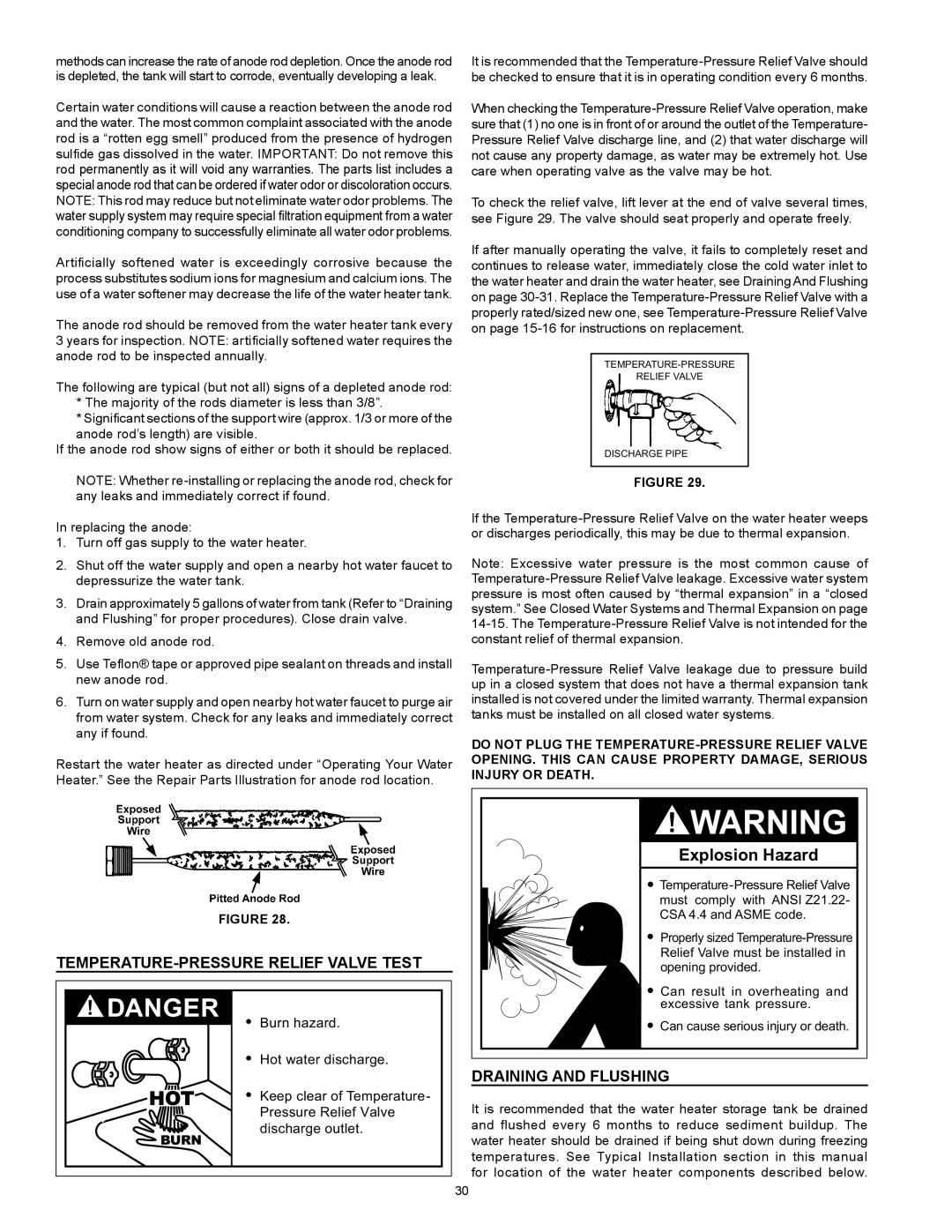

The following are typical (but not all) signs of a depleted anode rod: * The majority of the rods diameter is less than 3/8”.

*Significant sections of the support wire (approx. 1/3 or more of the anode rod’s length) are visible.

If the anode rod show signs of either or both it should be replaced.

NOTE: Whether

In replacing the anode:

1.Turn off gas supply to the water heater.

2.Shut off the water supply and open a nearby hot water faucet to depressurize the water tank.

3.Drain approximately 5 gallons of water from tank (Refer to “Draining and Flushing” for proper procedures). Close drain valve.

4.Remove old anode rod.

5.Use Teflon® tape or approved pipe sealant on threads and install new anode rod.

6.Turn on water supply and open nearby hot water faucet to purge air from water system. Check for any leaks and immediately correct any if found.

Restart the water heater as directed under “Operating Your Water Heater.” See the Repair Parts Illustration for anode rod location.

It is recommended that the

When checking the

To check the relief valve, lift lever at the end of valve several times, see Figure 29. The valve should seat properly and operate freely.

If after manually operating the valve, it fails to completely reset and continues to release water, immediately close the cold water inlet to the water heater and drain the water heater, see Draining And Flushing on page

RELIEF VALVE

DISCHARGE PIPE

Figure 29.

If the

Note: Excessive water pressure is the most common cause of

DO NOT PLUG THE

Figure 28.

Temperature-Pressure Relief Valve Test

Explosion Hazard

![]()

![]() Properly sized

Properly sized

![]() DANGER

DANGER

•Burn hazard.

•Hot water discharge.

•Keep clear of Temperature- Pressure Relief Valve discharge outlet.

Can result in overheating and excessive tank pressure.

![]() Can cause serious injury or death.

Can cause serious injury or death.

DRAINING AND FLUSHING

It is recommended that the water heater storage tank be drained and flushed every 6 months to reduce sediment buildup. The water heater should be drained if being shut down during freezing temperatures. See Typical Installation section in this manual for location of the water heater components described below.

30