cm45 s specifications

The Frymaster CM45 S is a high-performance commercial deep fryer designed to meet the demands of busy kitchens while ensuring consistent cooking results and energy efficiency. The unit is particularly well-suited for restaurants, cafes, and fast-food establishments, where high-quality fried foods are a staple on the menu.One of the most notable features of the Frymaster CM45 S is its high-capacity design. This fryer can accommodate large volumes of food, making it ideal for high-demand situations. With a frying capacity of 45 pounds, operators can efficiently prepare items like French fries, chicken, and onion rings in large batches, allowing for streamlined service during peak hours.

The Frymaster CM45 S is equipped with a state-of-the-art digital control system that ensures precise temperature regulation. This feature helps maintain consistent frying temperatures, crucial for achieving optimal texture and flavor in fried foods. The digital display is user-friendly, allowing chefs to monitor and adjust settings with ease. Additionally, the fryer includes programmable timers, which enhance operational efficiency by minimizing the risk of overcooking.

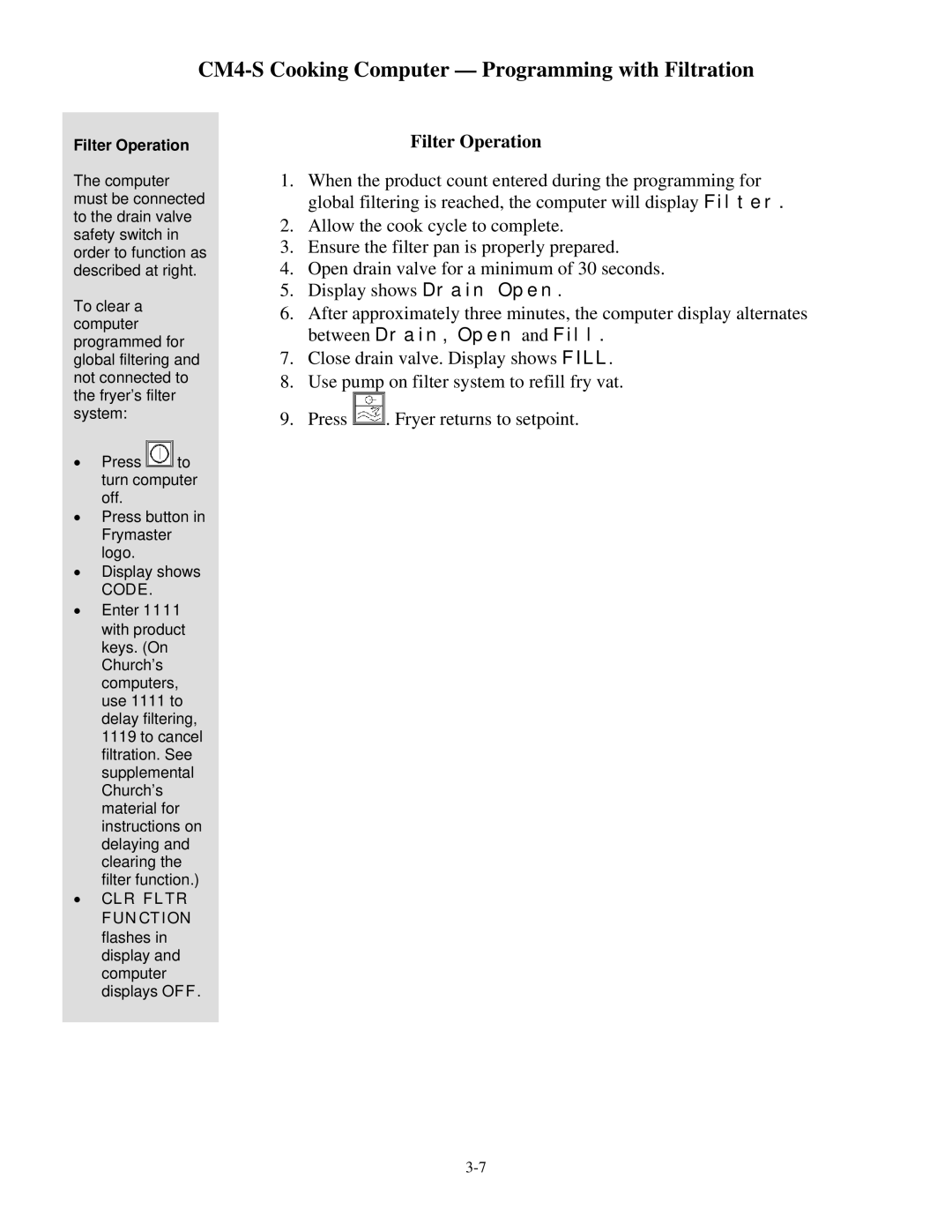

Another significant characteristic of the CM45 S is its innovative oil filtration system. This technology not only extends the life of the frying oil but also improves the quality of the fried products. By removing food particles and impurities, the filtration system helps maintain the oil's integrity, resulting in cleaner and more flavorful fried items.

Furthermore, the Frymaster CM45 S incorporates energy-efficient heating elements that provide quick heat-up times and reduce energy consumption. This feature not only saves costs but also contributes to a more sustainable operation. The unit is designed with a durable stainless steel construction, ensuring longevity and resistance to the wear and tear of a commercial environment.

Safety is another priority in the design of the CM45 S. The fryer is equipped with a variety of safety features, including a built-in thermal protection system that prevents overheating. This minimizes the risk of accidents and provides peace of mind for operators.

In summary, the Frymaster CM45 S stands out in the commercial frying equipment market due to its high capacity, precise digital controls, effective oil filtration, energy efficiency, and sturdy construction. These features combine to deliver an exceptional frying experience that meets the needs of any busy kitchen, making the Frymaster CM45 S one of the best choices for culinary professionals.