3.Connect plastic tubing of a digital or inclined water manometer with a

4.Turn heater on and wait until blower motor is activated.

5.Observe air pressure from manometer. This should be higher than the set point indicated below for correct operation.

Model | Operating Pressure | Model | Operating Pressure |

PTS/U 40/25 | 0.98” W.C. Hot | PTS/U 125/80 | 0.39” W.C. Hot |

PTS/U 50/30 | 0.98” W.C. Hot | PTS/U 150/100 | 0.39” W.C. Hot |

PTS/U 75/50 | 0.70” W.C. Hot | PTS/U 175/110 | 0.39” W.C. Hot |

PTS/U 100/65 | 0.70” W.C. Hot | PTS/U 200/125 | 0.39” W.C. Hot |

All pressures are with the heater in operation for at least 15 minutes.

23.4) IGNITION SYSTEM CHECKS

TO CHECK FLAME SENSOR CIRCUIT.

Flame current is the current which passes through the flame from the sensor to ground. The minimum flame current necessary to keep the system from lockout is 0.7 microamps.

a)Turn off heater at thermostat.

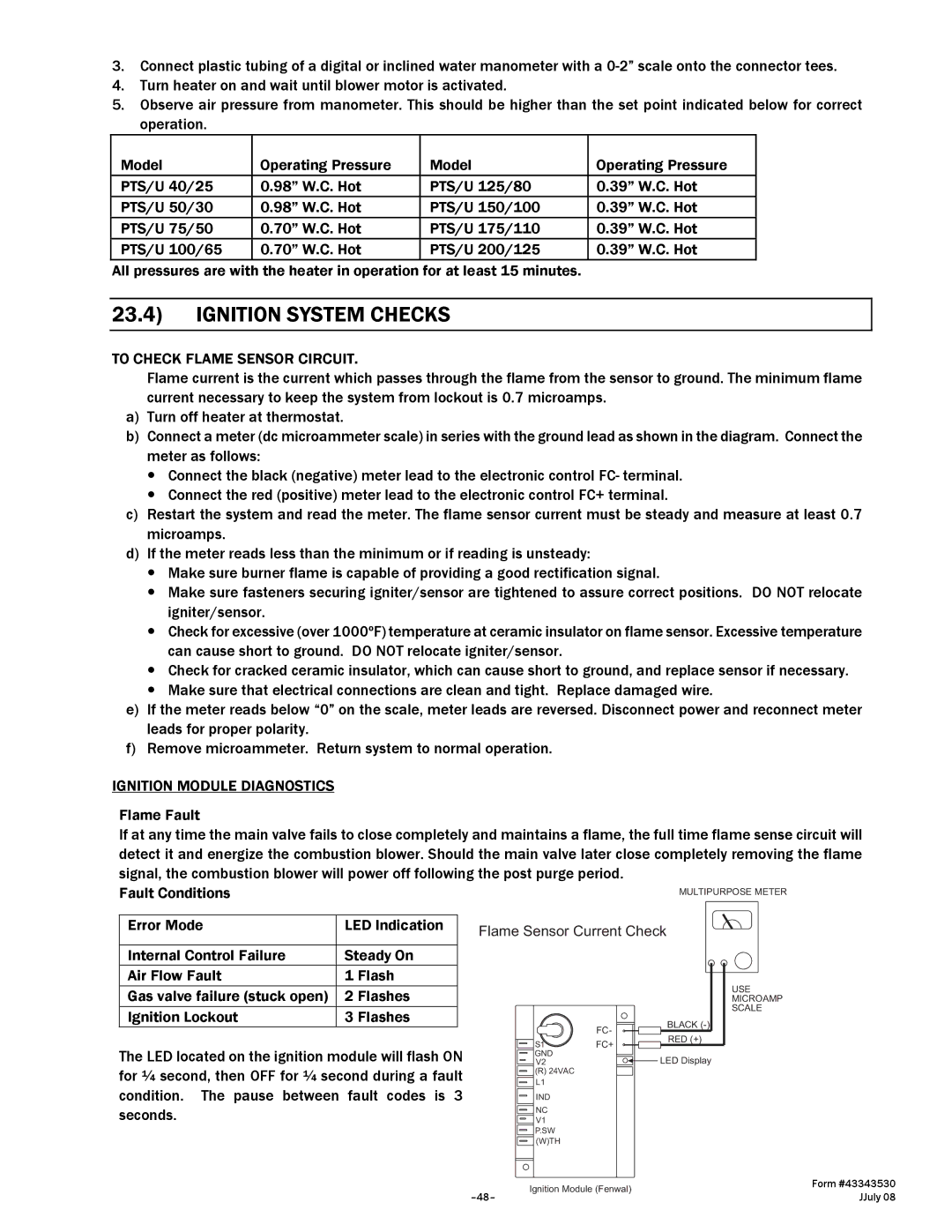

b)Connect a meter (dc microammeter scale) in series with the ground lead as shown in the diagram. Connect the meter as follows:

Connect the black (negative) meter lead to the electronic control FC- terminal. Connect the red (positive) meter lead to the electronic control FC+ terminal.

c)Restart the system and read the meter. The flame sensor current must be steady and measure at least 0.7 microamps.

d)If the meter reads less than the minimum or if reading is unsteady:

Make sure burner flame is capable of providing a good rectification signal.

Make sure fasteners securing igniter/sensor are tightened to assure correct positions. DO NOT relocate igniter/sensor.

Check for excessive (over 1000ºF) temperature at ceramic insulator on flame sensor. Excessive temperature can cause short to ground. DO NOT relocate igniter/sensor.

Check for cracked ceramic insulator, which can cause short to ground, and replace sensor if necessary. Make sure that electrical connections are clean and tight. Replace damaged wire.

e)If the meter reads below “0” on the scale, meter leads are reversed. Disconnect power and reconnect meter leads for proper polarity.

f)Remove microammeter. Return system to normal operation.

IGNITION MODULE DIAGNOSTICS

Flame Fault

If at any time the main valve fails to close completely and maintains a flame, the full time flame sense circuit will detect it and energize the combustion blower. Should the main valve later close completely removing the flame signal, the combustion blower will power off following the post purge period.

Fault Conditions

Error Mode | LED Indication |

|

|

Internal Control Failure | Steady On |

Air Flow Fault | 1 Flash |

Gas valve failure (stuck open) | 2 Flashes |

Ignition Lockout | 3 Flashes |

The LED located on the ignition module will flash ON for ¼ second, then OFF for ¼ second during a fault condition. The pause between fault codes is 3 seconds.

Flame Sensor Current Check

| FC- | BLACK | |

| RED (+) | ||

S1 | FC+ | ||

| |||

GND |

| LED Display | |

V2 |

|

(R)24VAC

L1

IND

NC

V1

P.SW

(W)TH

| Ignition Module (Fenwal) | Form #43343530 | |

JJuly 08 | |||

|