Startup

NOTICE

Proper system setup, startup, and shutdown procedures are critical to electrical equip- ment reliability. The following procedures ensure steady voltage. Failure to follow these procedures will cause voltage fluctua- tions that can damage electrical equipment and void the warranty.

Do not operate Reactor without all covers and shrouds in place.

1.Check generator fuel level.

Running out of fuel will cause voltage fluc- tuations that can damage electrical equip- ment.

2.Ensure the main breaker on the genera- tor is in the off position.

3.Start the generator. Allow it to reach full operating temperature.

4.Close the bleed valve on the air com- pressor.

5.Switch on the air compressor starter and air dryer, if included.

6.Turn on power to the Reactor.

7.Load fluid with feed pumps

The Reactor is tested with oil at the fac- tory. Flush out the oil with a compatible solvent before spraying. See page 47.

Startup

a.Check that all Setup steps are com- plete.

b.Check that inlet screens are clean before daily startup, page 45.

c.Check level and condition of ISO lube daily, page 44.

d.Turn on component B agitator, if used.

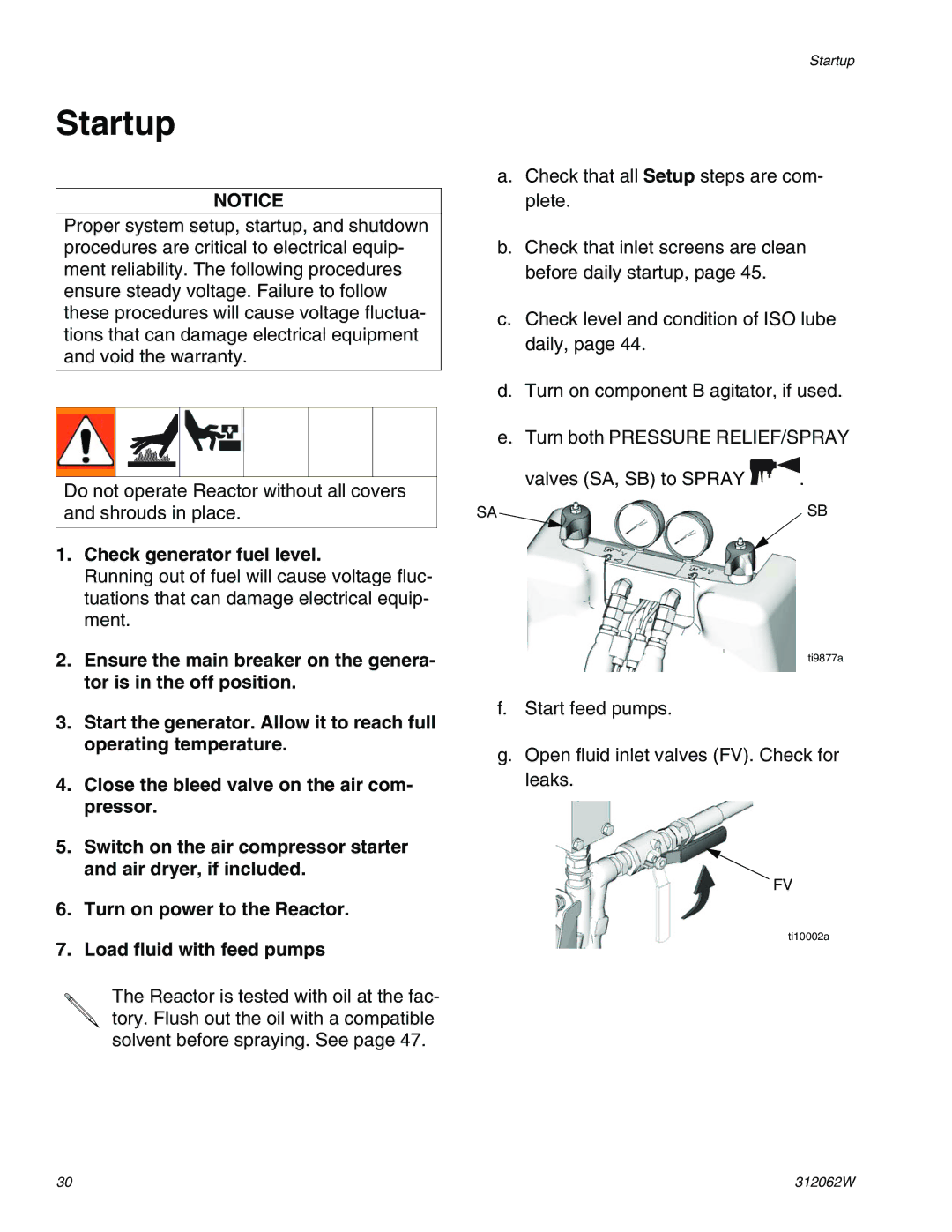

e.Turn both PRESSURE RELIEF/SPRAY

valves (SA, SB) to SPRAY | . |

SA | SB |

ti9877a

f.Start feed pumps.

g.Open fluid inlet valves (FV). Check for leaks.

FV

ti10002a

30 | 312062W |