Maintenance

•Inspect hydraulic and fluid lines for leaks daily.

•Clean up all hydraulic leaks; identify and repair cause of leak.

•Inspect fluid inlet strainer screens daily, see below.

•Grease circulation valves weekly with Fusion grease (117773).

ti9879a

•Inspect ISO lubricant level and condition daily, see page 46. Refill or replace as needed.

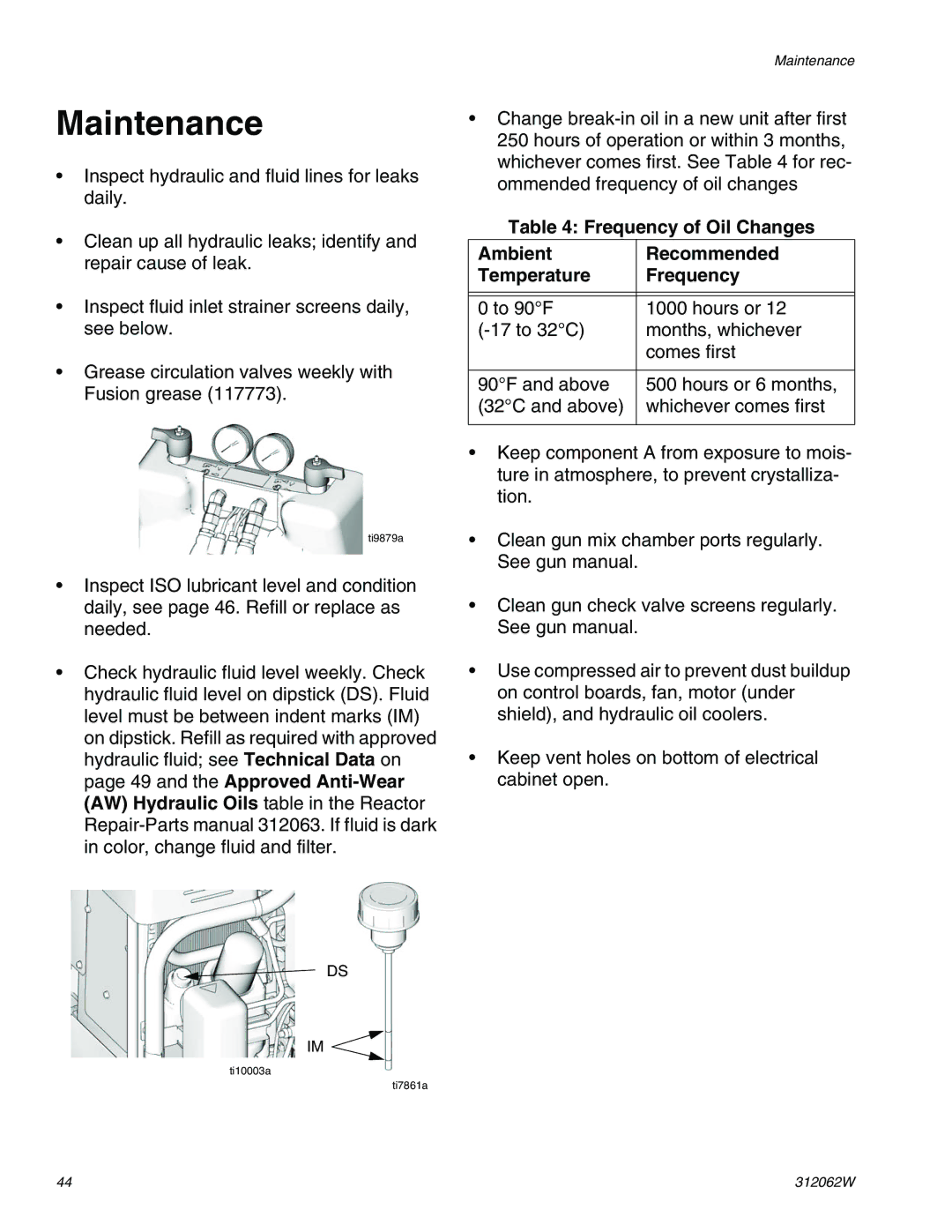

•Check hydraulic fluid level weekly. Check hydraulic fluid level on dipstick (DS). Fluid level must be between indent marks (IM) on dipstick. Refill as required with approved hydraulic fluid; see Technical Data on page 49 and the Approved

Maintenance

•Change

Table 4: Frequency of Oil Changes

Ambient | Recommended |

Temperature | Frequency |

|

|

|

|

0 to 90°F | 1000 hours or 12 |

months, whichever | |

| comes first |

|

|

90°F and above | 500 hours or 6 months, |

(32°C and above) | whichever comes first |

|

|

•Keep component A from exposure to mois- ture in atmosphere, to prevent crystalliza- tion.

•Clean gun mix chamber ports regularly. See gun manual.

•Clean gun check valve screens regularly. See gun manual.

•Use compressed air to prevent dust buildup on control boards, fan, motor (under shield), and hydraulic oil coolers.

•Keep vent holes on bottom of electrical cabinet open.

DS

IM ![]()

ti10003a

ti7861a

44 | 312062W |