Setup

12.Ground system

a.Reactor: is grounded through power cord. See page 25.

b.Spray gun: connect whip hose ground wire to FTS, page 27. Do not discon- nect wire or spray without whip hose.

c.Fluid supply containers: follow your local code.

d.Object being sprayed: follow your local code.

e.Solvent pails used when flushing: follow your local code. Use only metal pails, which are conductive, placed on a grounded surface. Do not place pail on a nonconductive surface, such as paper or cardboard, which interrupts ground- ing continuity

f.To maintain grounding continuity when flushing or relieving pressure, hold a metal part of spray gun firmly to the side of a grounded metal pail, then trigger gun.

13.Check hydraulic fluid level

Hydraulic reservoir is filled at the factory. Check fluid level before operating the first time, and weekly thereafter. See Mainte- nance, page 44.

14.Lubrication system setup

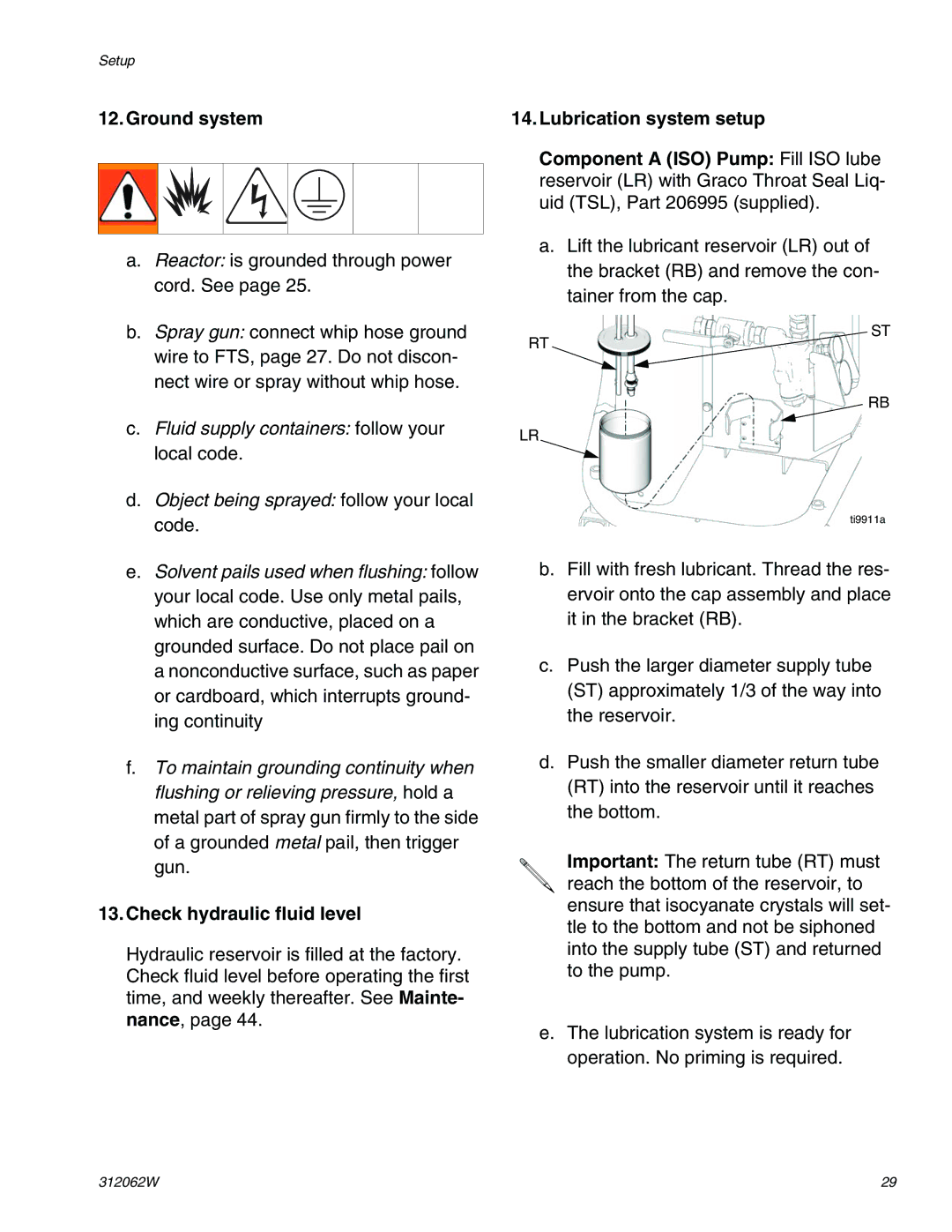

Component A (ISO) Pump: Fill ISO lube reservoir (LR) with Graco Throat Seal Liq- uid (TSL), Part 206995 (supplied).

a.Lift the lubricant reservoir (LR) out of the bracket (RB) and remove the con- tainer from the cap.

![]() ST

ST

RT ![]()

![]() RB

RB

LR![]()

ti9911a

b.Fill with fresh lubricant. Thread the res- ervoir onto the cap assembly and place it in the bracket (RB).

c.Push the larger diameter supply tube (ST) approximately 1/3 of the way into the reservoir.

d.Push the smaller diameter return tube (RT) into the reservoir until it reaches the bottom.

Important: The return tube (RT) must reach the bottom of the reservoir, to ensure that isocyanate crystals will set- tle to the bottom and not be siphoned into the supply tube (ST) and returned to the pump.

e.The lubrication system is ready for operation. No priming is required.

312062W | 29 |