SECTION 6: OPERATIONS

Your safety is important! Please follow the warnings below during this entire section:

Operating this equipment creates the potential for flying debris to cause eye injury. Always wear safety glasses when operating equipment. Everyday glasses or reading glasses only have impact resistant lenses, they are not safety glasses. Be cer- tain the safety glasses you wear meet the appropriate standards of the American National Standards Institute (ANSI).

![]() Keep loose clothing out of the way of machinery and keep hair pulled back during operations.

Keep loose clothing out of the way of machinery and keep hair pulled back during operations.

Using this machine pro- duces sawdust that may cause short and long- term respiratory illness. Always wear a dust mask when operating this machine.

Stock Inspection & Requirements

Here are some rules to follow when choosing and cutting stock:

•If the stock has large or loose knots, find another workpiece. Knots in a workpiece can be dangerous to the operator, as well as destructive to equipment.

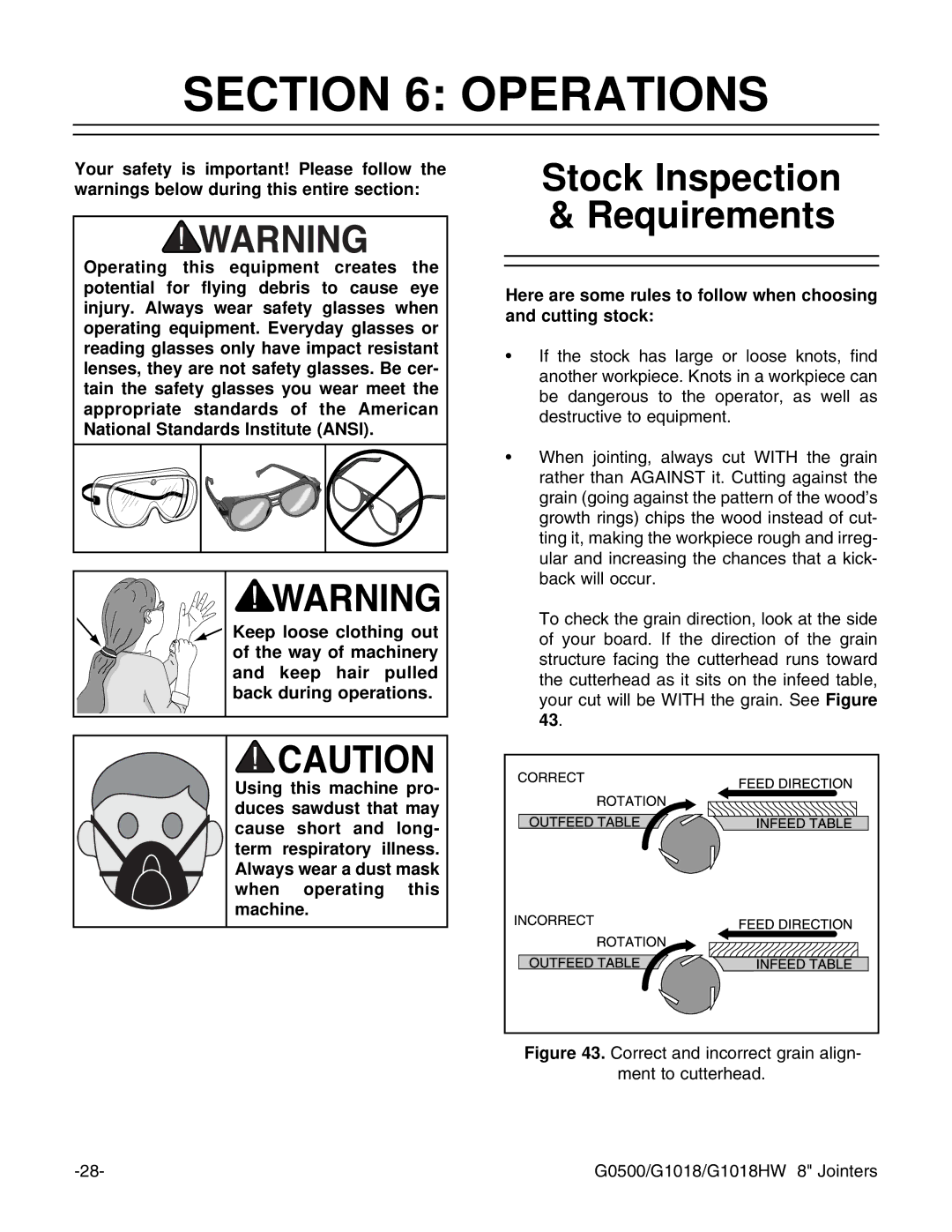

•When jointing, always cut WITH the grain rather than AGAINST it. Cutting against the grain (going against the pattern of the wood’s growth rings) chips the wood instead of cut- ting it, making the workpiece rough and irreg- ular and increasing the chances that a kick- back will occur.

To check the grain direction, look at the side of your board. If the direction of the grain structure facing the cutterhead runs toward the cutterhead as it sits on the infeed table, your cut will be WITH the grain. See Figure 43.

Figure 43. Correct and incorrect grain align-

ment to cutterhead.

G0500/G1018/G1018HW 8" Jointers |