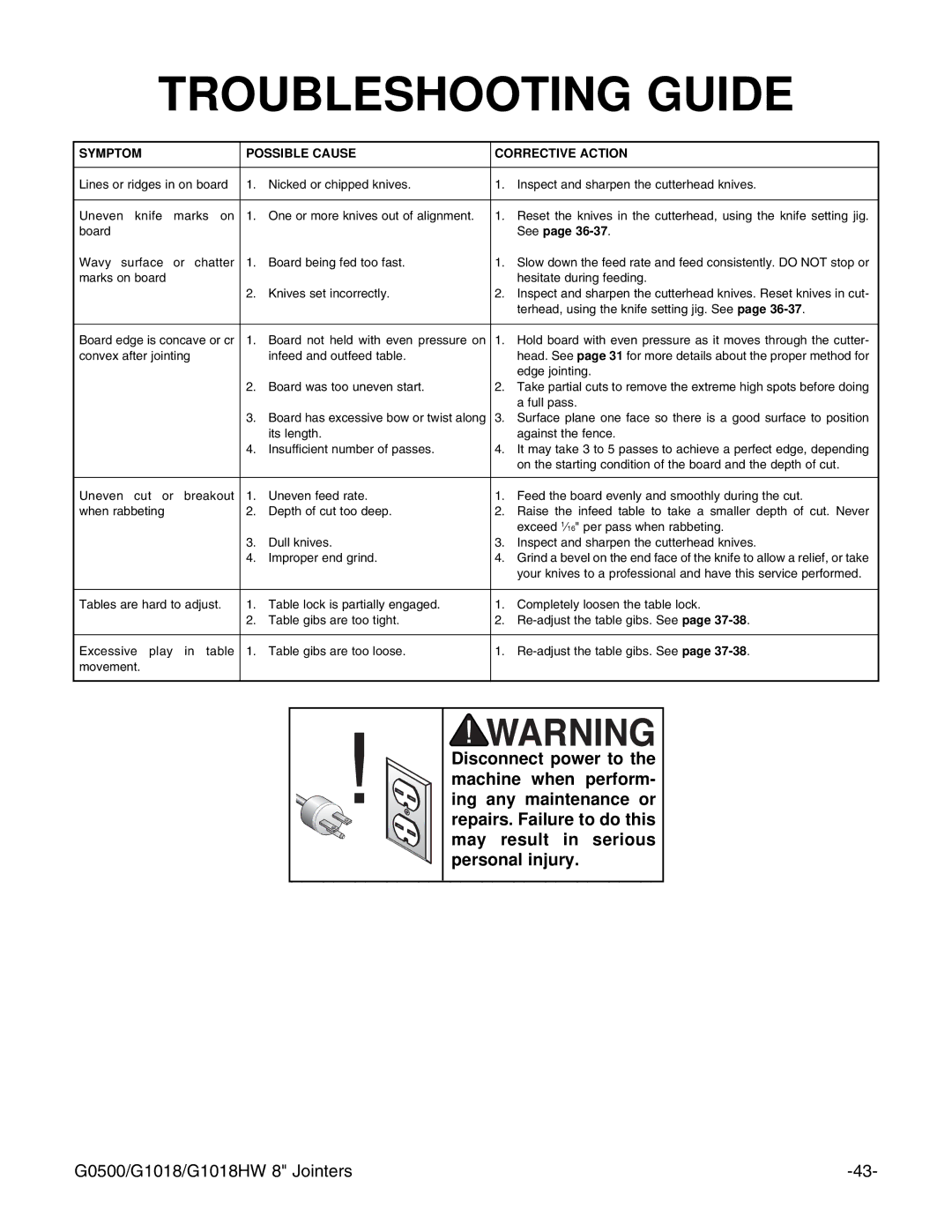

TROUBLESHOOTING GUIDE

SYMPTOM |

|

| POSSIBLE CAUSE | CORRECTIVE ACTION | ||

|

|

|

|

| ||

Lines or ridges in on board | 1. | Nicked or chipped knives. | 1. | Inspect and sharpen the cutterhead knives. | ||

|

|

|

|

|

| |

Uneven knife | marks on | 1. | One or more knives out of alignment. | 1. | Reset the knives in the cutterhead, using the knife setting jig. | |

board |

|

|

|

|

| See page |

Wavy surface | or | chatter | 1. | Board being fed too fast. | 1. | Slow down the feed rate and feed consistently. DO NOT stop or |

marks on board |

|

|

|

|

| hesitate during feeding. |

|

|

| 2. | Knives set incorrectly. | 2. | Inspect and sharpen the cutterhead knives. Reset knives in cut- |

|

|

|

|

|

| terhead, using the knife setting jig. See page |

|

|

|

|

| ||

Board edge is concave or cr | 1. | Board not held with even pressure on | 1. | Hold board with even pressure as it moves through the cutter- | ||

convex after jointing |

|

| infeed and outfeed table. |

| head. See page 31 for more details about the proper method for | |

|

|

|

|

|

| edge jointing. |

|

|

| 2. | Board was too uneven start. | 2. | Take partial cuts to remove the extreme high spots before doing |

|

|

|

|

|

| a full pass. |

|

|

| 3. | Board has excessive bow or twist along | 3. | Surface plane one face so there is a good surface to position |

|

|

|

| its length. |

| against the fence. |

|

|

| 4. | Insufficient number of passes. | 4. | It may take 3 to 5 passes to achieve a perfect edge, depending |

|

|

|

|

|

| on the starting condition of the board and the depth of cut. |

|

|

|

|

|

| |

Uneven cut or | breakout | 1. | Uneven feed rate. | 1. | Feed the board evenly and smoothly during the cut. | |

when rabbeting |

|

| 2. | Depth of cut too deep. | 2. | Raise the infeed table to take a smaller depth of cut. Never |

|

|

|

|

|

| exceed 1⁄16" per pass when rabbeting. |

|

|

| 3. | Dull knives. | 3. | Inspect and sharpen the cutterhead knives. |

|

|

| 4. | Improper end grind. | 4. | Grind a bevel on the end face of the knife to allow a relief, or take |

|

|

|

|

|

| your knives to a professional and have this service performed. |

|

|

|

|

| ||

Tables are hard to adjust. | 1. | Table lock is partially engaged. | 1. | Completely loosen the table lock. | ||

|

|

| 2. | Table gibs are too tight. | 2. | |

|

|

|

|

|

|

|

Excessive play | in | table | 1. | Table gibs are too loose. | 1. | |

movement. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Disconnect power to the machine when perform- ing any maintenance or repairs. Failure to do this may result in serious personal injury.

G0500/G1018/G1018HW 8" Jointers |