Knife Inspection

The knives were set to their proper height at the factory, but we recommend that you inspect them to ensure proper operation and table setup.

To inspect the knife height:

1.Make sure that the power has not been con- nected to the machine at this point in the setup process!

2.Remove the belt guard shown in Figure 27.

Figure 27. Removing belt guard.

3.Using the cutterhead pulley, rotate the cut- terhead to make one of the knives accessible to the knife jig. Lower the tables if it is nec- essary to make more room.

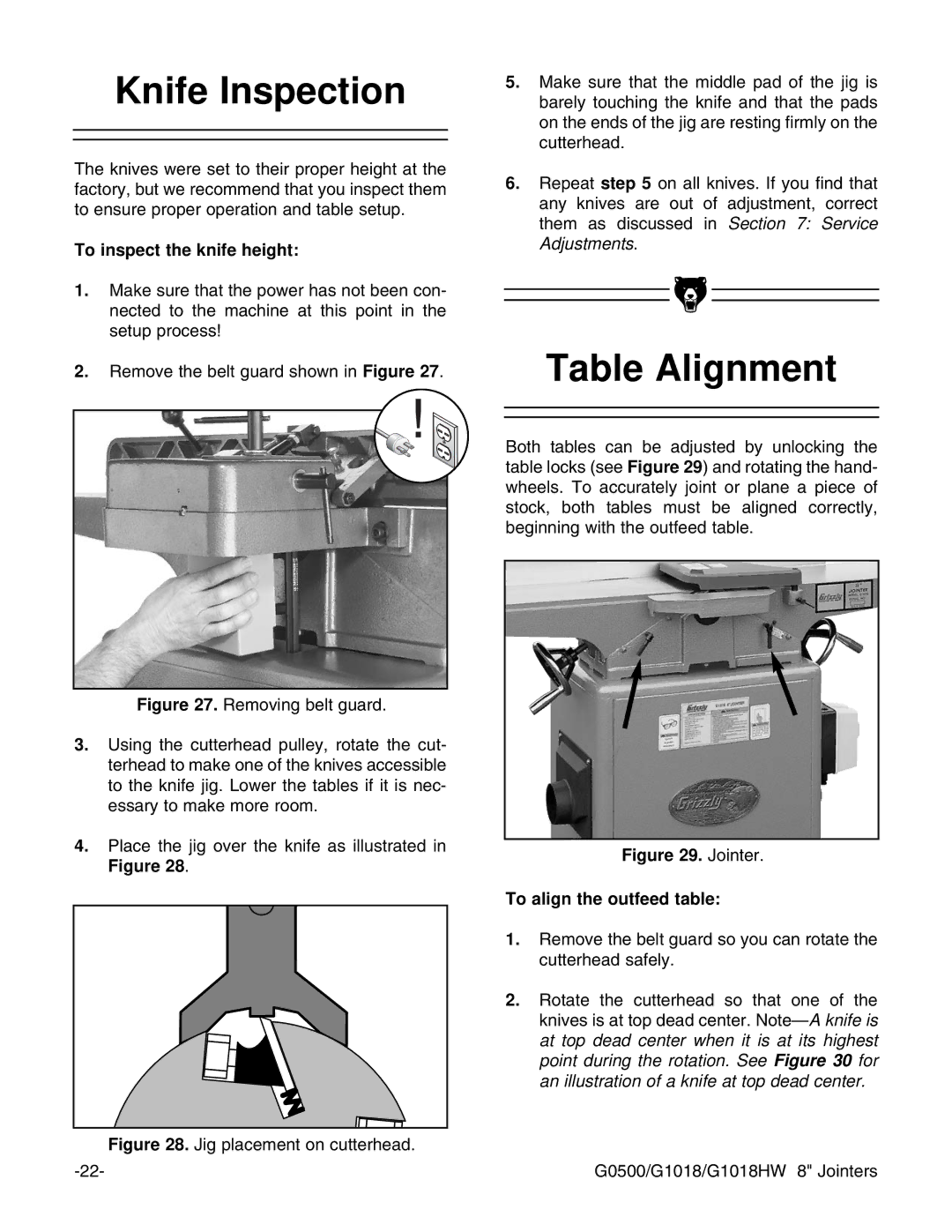

4.Place the jig over the knife as illustrated in Figure 28.

Figure 28. Jig placement on cutterhead.

5.Make sure that the middle pad of the jig is barely touching the knife and that the pads on the ends of the jig are resting firmly on the cutterhead.

6.Repeat step 5 on all knives. If you find that any knives are out of adjustment, correct them as discussed in Section 7: Service Adjustments.

Table Alignment

Both tables can be adjusted by unlocking the table locks (see Figure 29) and rotating the hand- wheels. To accurately joint or plane a piece of stock, both tables must be aligned correctly, beginning with the outfeed table.

Figure 29. Jointer.

To align the outfeed table:

1.Remove the belt guard so you can rotate the cutterhead safely.

2.Rotate the cutterhead so that one of the knives is at top dead center.

G0500/G1018/G1018HW 8" Jointers