•Make sure that any stock you process with the jointer is clean and free of any dirt, nails, staples, tiny rocks or any other foreign objects that may damage the jointer blades.

•Only process natural wood fiber through your jointer. Never joint MDF, particle board, ply- wood, laminates or other synthetically made materials.

•Make sure any stock you joint is properly dried. Wood with a moisture content over 20% will cause unnecessary wear on the knives and will produce undesirable results.

NOTICE

Occasionally, you will find woods that defy all rules. In those rare cases, it is best to feed the workpiece slowly and take several shallow cuts. A few extra passes will hurt much less than a ruined workpiece.

Squaring Stock

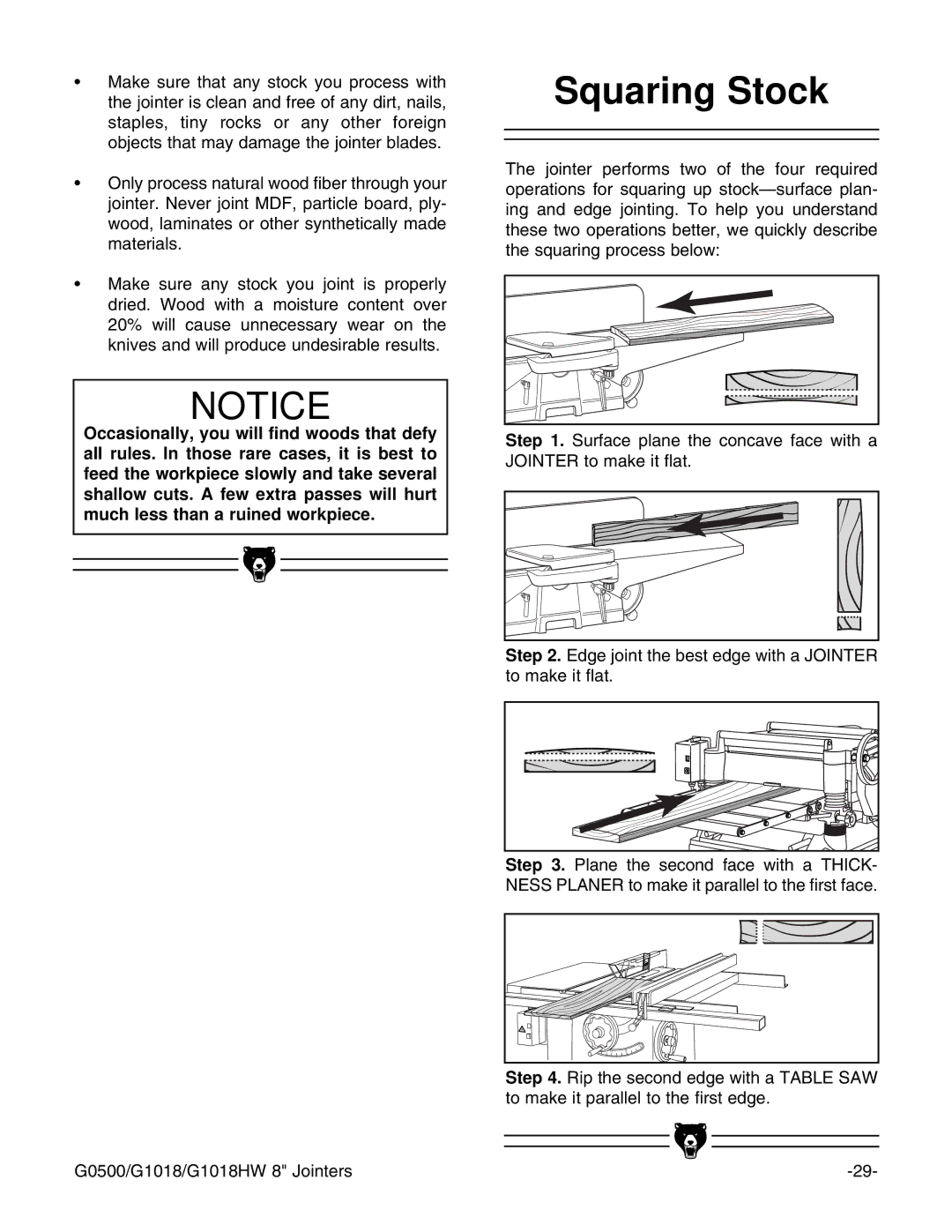

The jointer performs two of the four required operations for squaring up

Step 1. Surface plane the concave face with a JOINTER to make it flat.

Step 2. Edge joint the best edge with a JOINTER to make it flat.

Step 3. Plane the second face with a THICK- NESS PLANER to make it parallel to the first face.

| 45 |

15 | 30 |

Step 4. Rip the second edge with a TABLE SAW to make it parallel to the first edge.

|

|

|

|

|

|

|

|

|

|

|

|

G0500/G1018/G1018HW 8" Jointers | |||