Blade Tension

The only way to accurately tension the blade on this machine is with a blade tensioner such as the Model H5408 on page 33. This method is for rough blade tensioning only.

Tools Needed | Qty |

Hex Wrench 4mm | 1 |

Wrench/Socket 17mm | 2 |

To adjust the tension: |

|

1.Disconnect the resaw from power!

2.Remove the upper plate shown in Figure 25.

Blade Guide

Upper Plate

Figure 25. Blade guide upper plate.

3.Loosen the vertical adjustment bolts shown in Figure 26 and lower the guide block.

Adjustment Bolts

Figure 26. Vertical adjustment bolts. One

adjustment bolt is not visible.

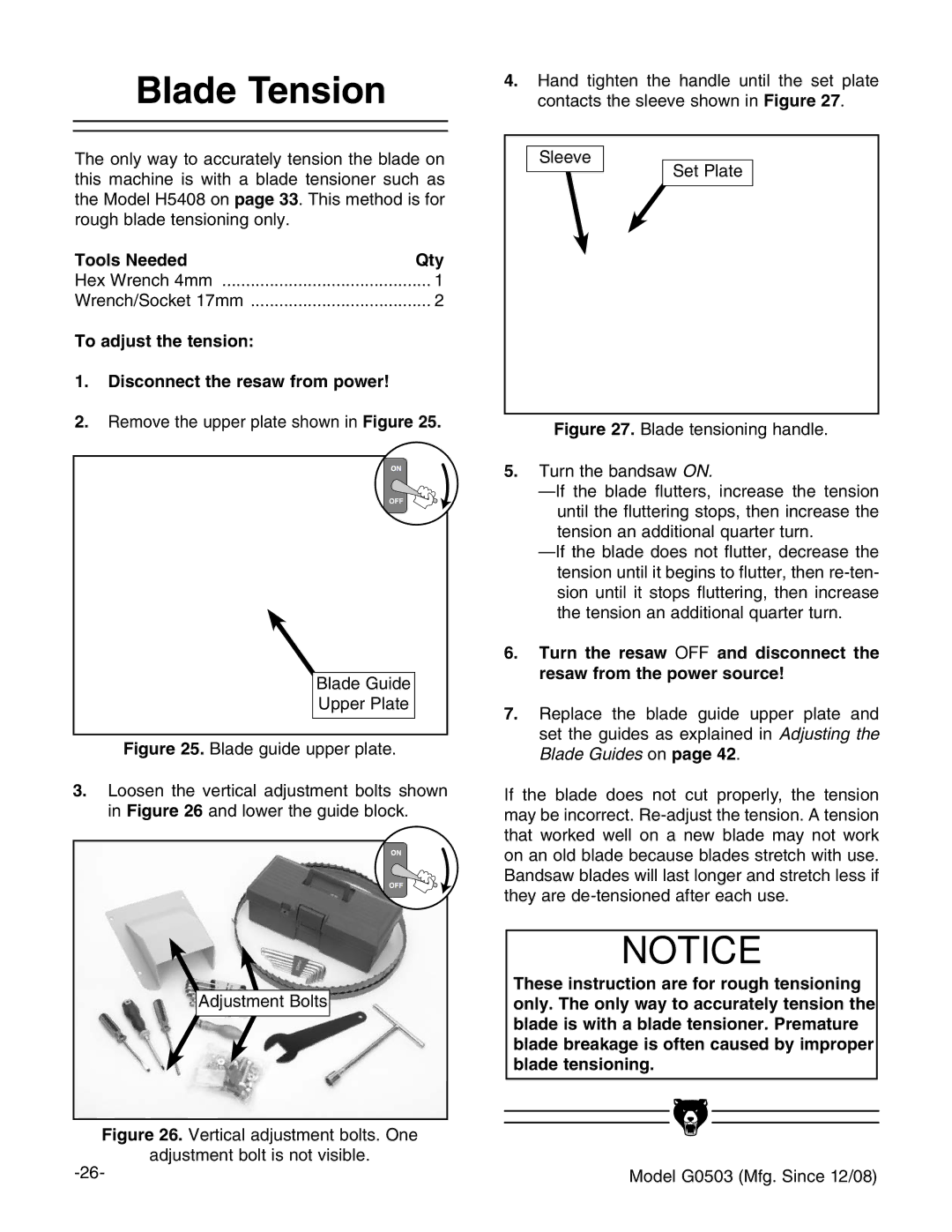

4.Hand tighten the handle until the set plate contacts the sleeve shown in Figure 27.

Sleeve

Set Plate

Figure 27. Blade tensioning handle.

5.Turn the bandsaw ON.

—If the blade flutters, increase the tension until the fluttering stops, then increase the tension an additional quarter turn.

—If the blade does not flutter, decrease the tension until it begins to flutter, then re-ten- sion until it stops fluttering, then increase the tension an additional quarter turn.

6.Turn the resaw OFF and disconnect the resaw from the power source!

7.Replace the blade guide upper plate and set the guides as explained in Adjusting the Blade Guides on page 42.

If the blade does not cut properly, the tension may be incorrect.

NOTICE

These instruction are for rough tensioning only. The only way to accurately tension the blade is with a blade tensioner. Premature blade breakage is often caused by improper blade tensioning.

Model G0503 (Mfg. Since 12/08)