Adjusting the

Support Wheel

The support wheel is positioned behind the blade to brace it from pushing backwards during a cut. Check the support wheel spacing each time a new blade is installed.

Tools Needed | Qty |

Wrench/Socket 17mm . | ..................................... 1 |

To adjust the support wheel:

1.Loosen the lock bolt shown in Figure 58.

Lock Bolt |

Adjustment Shaft |

Figure 58. Support wheel components.

2.Rotate the adjustment shaft until the support wheel is approximately 0.016" behind the back of the blade. Check with a feeler gauge or four thicknesses of a dollar bill.

3.Tighten the lock bolt.

4.Spin the wheels clockwise by hand. If the support wheels turn, increase the spacing between the blade and the bearing (the bearings should only turn when cutting).

Blade Elevation |

|

Gauge |

|

Tools Needed | Qty |

Wrench/Socket 17mm | 1 |

Calipers | 1 |

To adjust the blade elevation gauge: |

|

1.Adjust the blade height until the blade eleva- tion gauge reads 1⁄2".

2.Run a test piece through the resaw and measure the thickness of the test piece with calipers.

3.Disconnect the resaw from power!

4.Loosen the bolt holding the blade elevation pointer and adjust the pointer until it is set at the same thickness as the test piece.

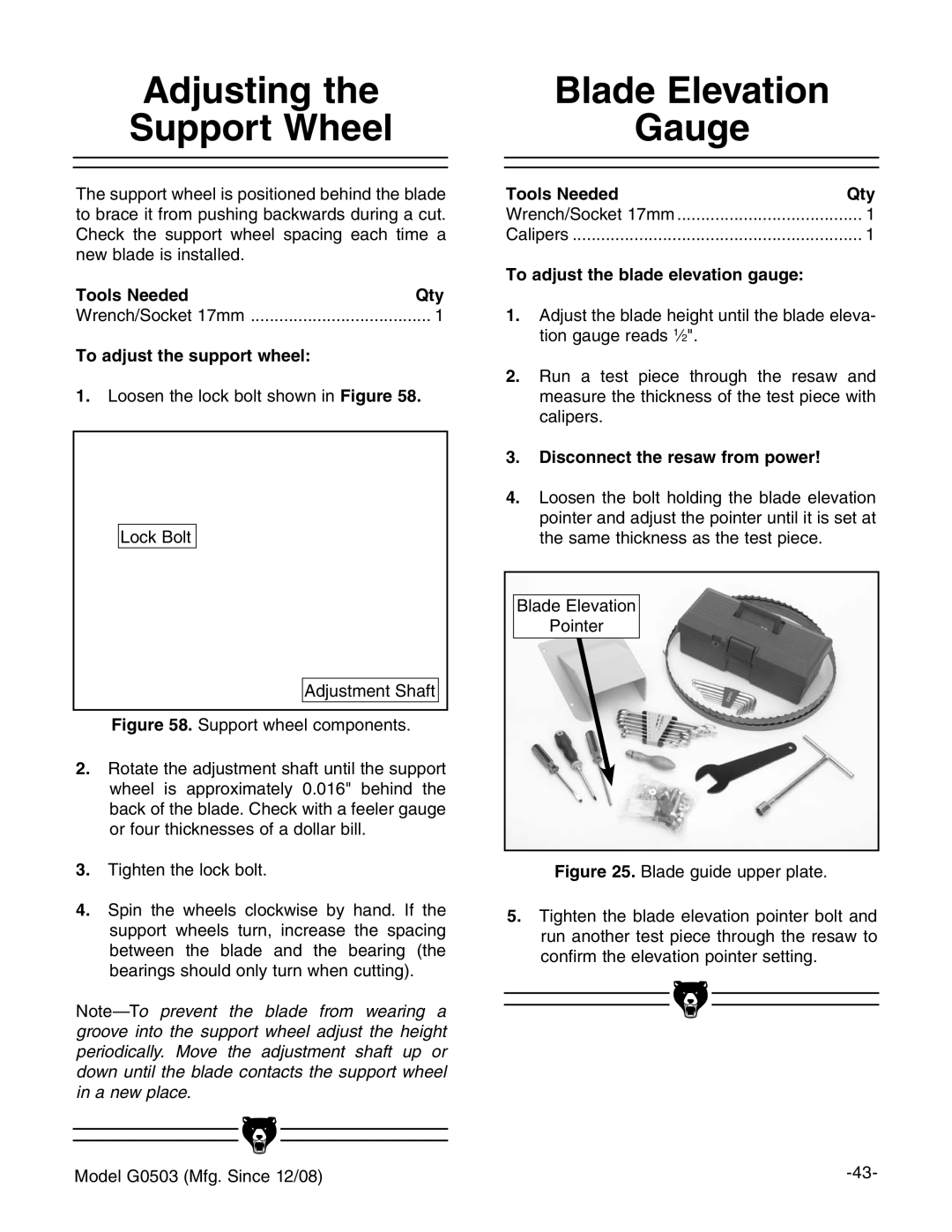

Blade Elevation

Pointer

Figure 25. Blade guide upper plate.

5.Tighten the blade elevation pointer bolt and run another test piece through the resaw to confirm the elevation pointer setting.

Model G0503 (Mfg. Since 12/08) |