Pressure Rollers

The pressure rollers hold the workpiece against the conveyor table for a smooth cut.

Tools Needed | Qty |

Hex Wrench 5mm | 1 |

Wrench/Socket 17mm | 2 |

Wrench 35mm | 1 |

To adjust the pressure rollers: |

|

1.Disconnect the resaw from power!

2.Loosen the jam nuts and hex bolts that secure the extension arm of the infeed pres- sure roller (see Figure 30).

Extension Arm

Adjustment Bolts

Figure 30. Infeed pressure roller.

3.Extend the pressure roller close to the blade and tighten the jam nuts and hex bolts. Make sure the extension arm can rotate without hitting the pressure roller on the blade.

NOTICE

The blade can move into the infeed pressure roller when the blade height is changed. Prevent damage by checking the pressure rollers each time the blade is adjusted.

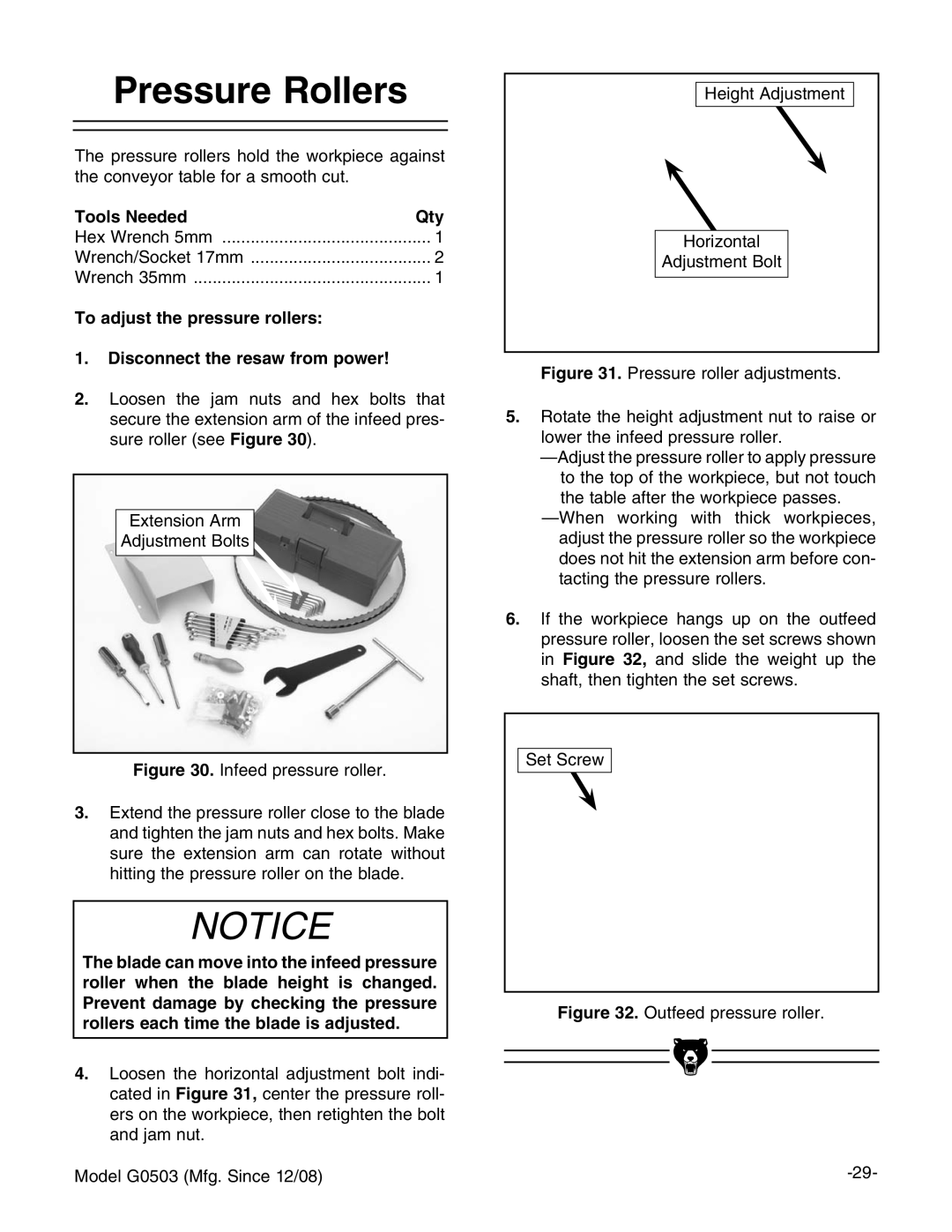

4.Loosen the horizontal adjustment bolt indi- cated in Figure 31, center the pressure roll- ers on the workpiece, then retighten the bolt and jam nut.

Model G0503 (Mfg. Since 12/08)

Height Adjustment

Horizontal

Adjustment Bolt

Figure 31. Pressure roller adjustments.

5.Rotate the height adjustment nut to raise or lower the infeed pressure roller.

6.If the workpiece hangs up on the outfeed pressure roller, loosen the set screws shown in Figure 32, and slide the weight up the shaft, then tighten the set screws.

Set Screw