Fence Movement: The fence has a lock that keeps it in position (Figure 23). To move the fence, loosen the lock and slide the fence where needed.

Fence![]()

Lock

Figure 23. Fence lock location.

Fence Tilting: The tilt lock (Figure 24) secures the fence at any position in the available range. The plunger locks into an indexing ring to eas- ily set the fence tilt to 90° after moving it. Two positive stops stop the fence at 45° inward and 45° outward (135°) for common 45° bevel cuts. Even when the fence is resting against the posi- tive stops, the tilt lock must be tightened before cutting.

Positive Stop |

|

| ||

Tilt | ||||

|

|

|

| Lock |

|

|

|

|

|

| Plunger |

|

|

|

Positive Stop

Figure 24. Tilt lock and plunger locations.

Stock Inspection and Requirements

Here are some rules to follow when choos- ing and jointing stock:

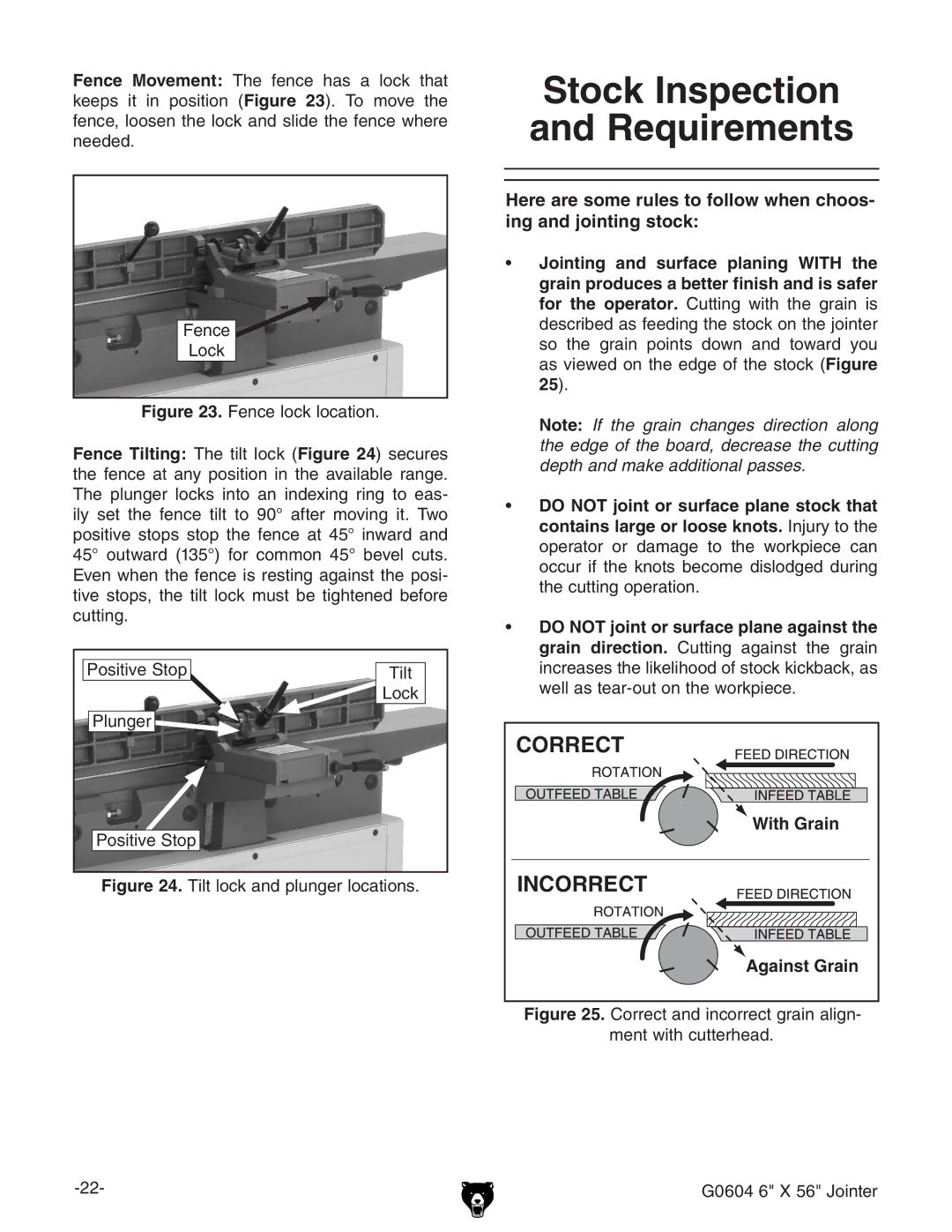

•Jointing and surface planing WITH the grain produces a better finish and is safer for the operator. Cutting with the grain is described as feeding the stock on the jointer so the grain points down and toward you as viewed on the edge of the stock (Figure 25).

Note: If the grain changes direction along the edge of the board, decrease the cutting depth and make additional passes.

•DO NOT joint or surface plane stock that contains large or loose knots. Injury to the operator or damage to the workpiece can occur if the knots become dislodged during the cutting operation.

•DO NOT joint or surface plane against the grain direction. Cutting against the grain increases the likelihood of stock kickback, as well as

�������

����������

���������

�������������

Figure 25. Correct and incorrect grain align-

ment with cutterhead.

G0604 6" X 56" Jointer |