5.Place the straightedge on the outfeed table so it hangs over the cutterhead, and lower the outfeed table until the straightedge is 0.062" (1⁄16") above the cutterhead body, as deter- mined by using the feeler gauge or combina- tion of feeler gauges (see Figure 57).

��������������

������������

�������������

������������

Figure 57. Using feeler gauge to set outfeed

table height.

6.Tighten the outfeed table lock located at the front of the machine, and tighten the positive stop bolts and jam nuts located at the back of the machine (see Figure 51).

7.Set the knife heights to the new outfeed table height.

G0604 6" X 56" Jointer

Setting Infeed Table

The infeed table on the Model G0604 has positive stop bolts that, when properly set up, allow the operator to quickly adjust the infeed table between finish/final cuts and shaping/heavy cuts.

We recommend setting the minimum depth of cut to 1⁄32" and the maximum depth of cut to 1⁄8" for most operations. DO NOT exceed 1⁄8" cut per pass on this machine or kickback and serious injury may occur!

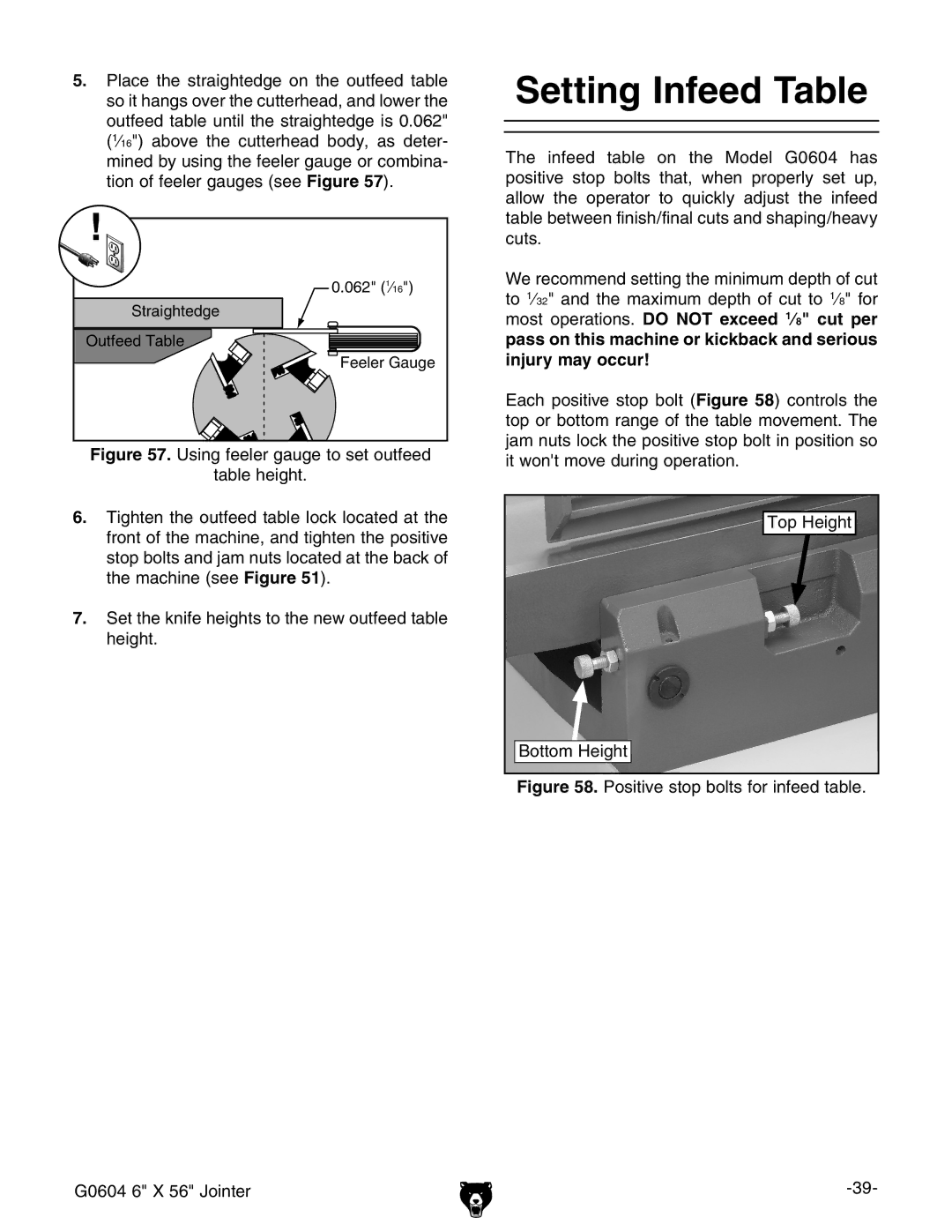

Each positive stop bolt (Figure 58) controls the top or bottom range of the table movement. The jam nuts lock the positive stop bolt in position so it won't move during operation.

Top Height

Bottom Height