6.Remove and clean the gibs and clean inside the cutterhead slot to remove all pitch or saw- dust. Coat the knives and gibs with a metal protectant (Page 28), then fit the gibs back in the cutterhead with the new knives.

7.Adjusting the knife heights:

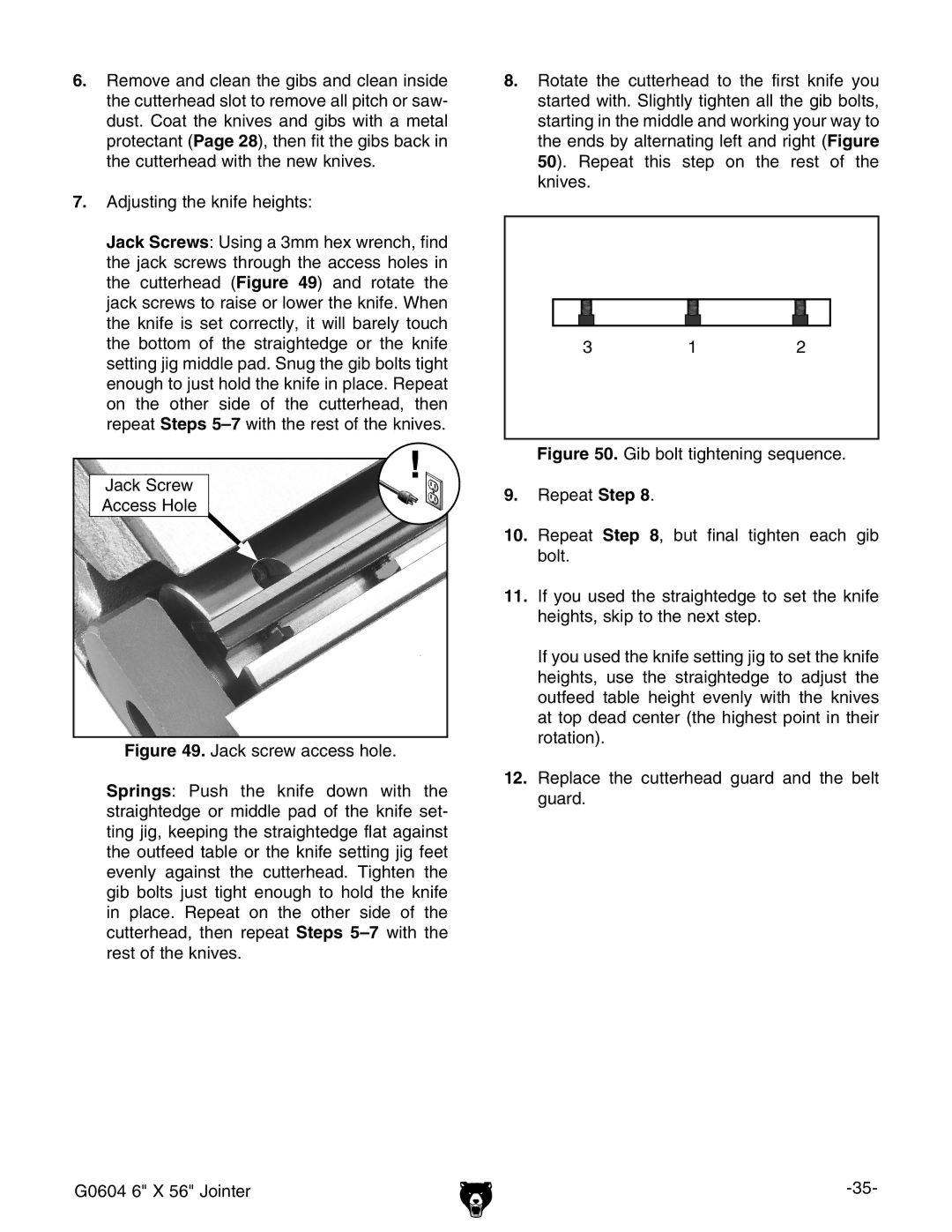

Jack Screws: Using a 3mm hex wrench, find the jack screws through the access holes in the cutterhead (Figure 49) and rotate the jack screws to raise or lower the knife. When the knife is set correctly, it will barely touch the bottom of the straightedge or the knife setting jig middle pad. Snug the gib bolts tight enough to just hold the knife in place. Repeat on the other side of the cutterhead, then repeat Steps

Jack Screw

Access Hole