OG-30X, OE-30X specifications

The Henny Penny OG-30X and OE-30X are advanced commercial cooking equipment designed to elevate food preparation in the fast-paced restaurant environment. These units, popular among professional chefs and culinary experts, feature innovative technologies that enhance cooking performance while ensuring consistency and quality.One of the standout characteristics of both the OG-30X and OE-30X models is their versatility. Designed to handle a wide variety of food items, these equipment types allow users to fry, grill, and roast without compromising on flavor. The OG-30X utilizes a unique open fryer design, allowing for easy access and maintenance, while the OE-30X features a more traditional, enclosed design for efficient cooking and heat retention.

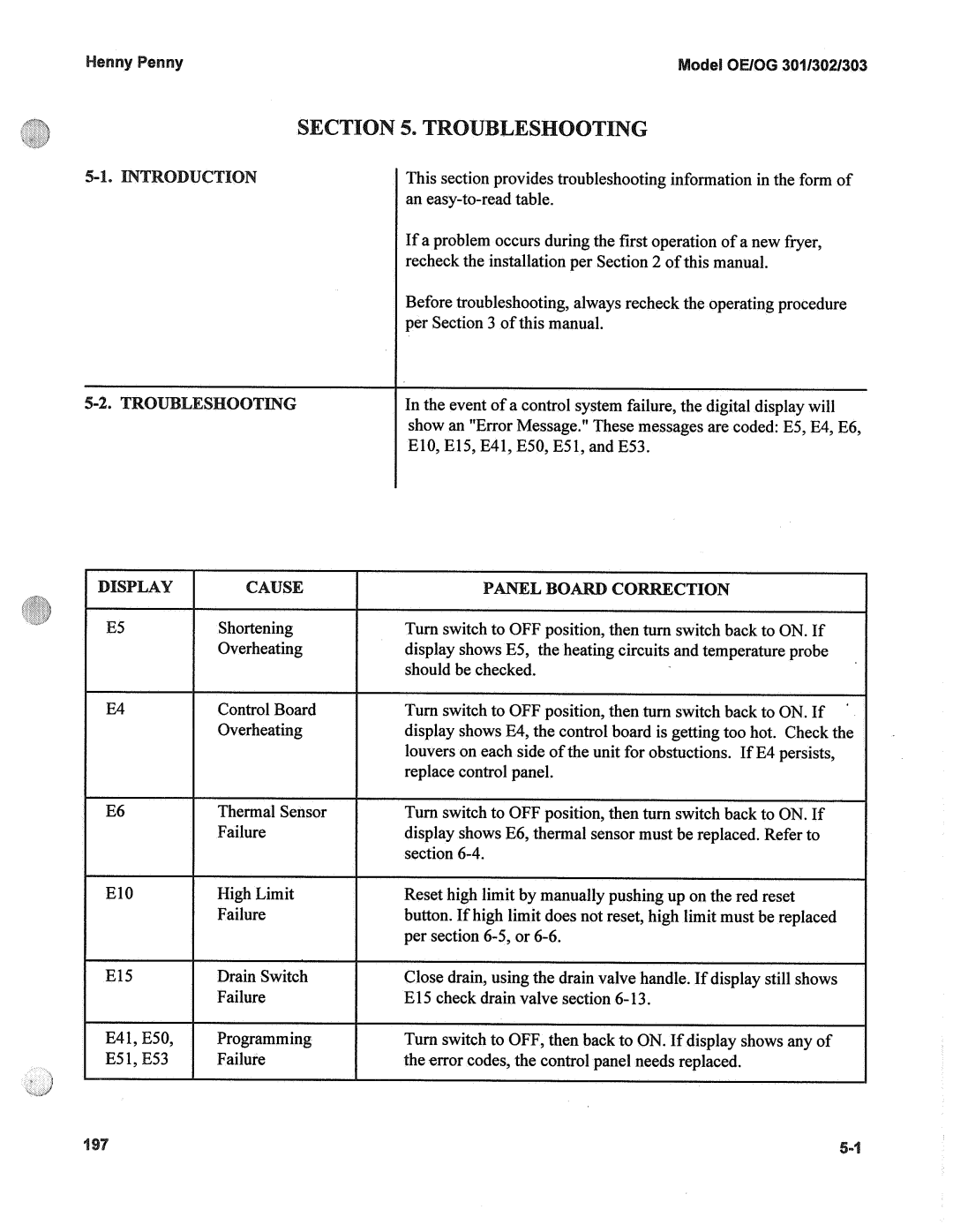

Both models come equipped with advanced digital controls that provide precise temperature management and timed cooking cycles. This user-friendly interface minimizes the learning curve for staff, enhancing productivity and ensuring that every meal is cooked to perfection. Moreover, the digital display simplifies the monitoring of cooking processes, which is vital in a busy restaurant environment.

In terms of energy efficiency, the Henny Penny OG-30X and OE-30X employ state-of-the-art heating technologies that reduce energy consumption without sacrificing performance. This results in lower operational costs and a smaller environmental footprint—a significant advantage for establishments aiming for sustainability.

The durability and build quality of these units are also noteworthy. Constructed from high-grade stainless steel, they are designed to stand up to the rigors of daily use in commercial kitchens. Additionally, the easy-to-clean design facilitates maintenance and promotes hygiene, which is crucial in any food service operation.

Safety features are paramount in the design of both models. They incorporate thermostatic controls to prevent overheating and emergency shut-off mechanisms that ensure operator safety. The Henny Penny OG-30X and OE-30X are built with the chef's welfare in mind, allowing them to focus on creativity and quality without worrying about potential hazards.

In conclusion, the Henny Penny OG-30X and OE-30X are equipped with an impressive range of features and technologies tailored for commercial kitchens. With their versatility, efficiency, and safety measures, these cooking units stand as reliable assets for any food service operation looking to enhance productivity and food quality.