English

ASSEMBLY PROCEDURES

![]() WARNING: To avoid an accident or personal injury, always confirm that the switch is turned OFF and the power plug has been disconnected from the receptacle before assembly of this tool.

WARNING: To avoid an accident or personal injury, always confirm that the switch is turned OFF and the power plug has been disconnected from the receptacle before assembly of this tool.

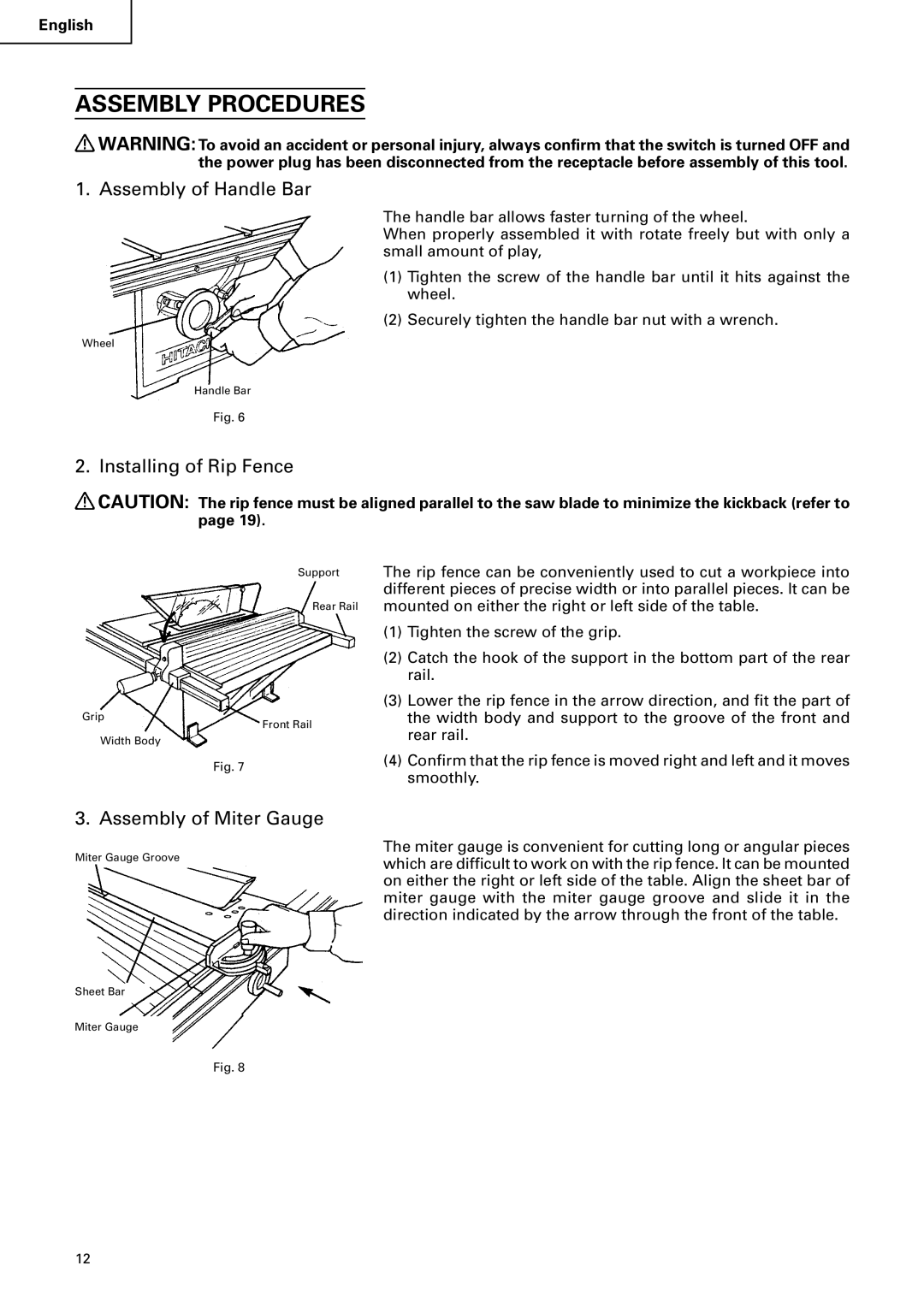

1. Assembly of Handle Bar

The handle bar allows faster turning of the wheel.

When properly assembled it with rotate freely but with only a small amount of play,

(1)Tighten the screw of the handle bar until it hits against the wheel.

(2)Securely tighten the handle bar nut with a wrench.

Wheel

Handle Bar

Fig. 6

2. Installing of Rip Fence

![]() CAUTION: The rip fence must be aligned parallel to the saw blade to minimize the kickback (refer to page 19).

CAUTION: The rip fence must be aligned parallel to the saw blade to minimize the kickback (refer to page 19).

Grip

Support

Rear Rail

Front Rail

The rip fence can be conveniently used to cut a workpiece into different pieces of precise width or into parallel pieces. It can be mounted on either the right or left side of the table.

(1) | Tighten the screw of the grip. |

(2) | Catch the hook of the support in the bottom part of the rear |

| rail. |

(3) | Lower the rip fence in the arrow direction, and fit the part of |

| the width body and support to the groove of the front and |

| rear rail. |

Width Body

Fig. 7

(4) Confirm that the rip fence is moved right and left and it moves |

smoothly. |

3. Assembly of Miter Gauge

Miter Gauge Groove

Sheet Bar

Miter Gauge

The miter gauge is convenient for cutting long or angular pieces which are difficult to work on with the rip fence. It can be mounted on either the right or left side of the table. Align the sheet bar of miter gauge with the miter gauge groove and slide it in the direction indicated by the arrow through the front of the table.

Fig. 8

12