Lubrication

Lubricate the areas indicated below every 12 months.

Lubricate blade angling trunnions with 6 or 7 drops of light machine oil.

Lubricate the blade height trunnion with 6 or 7 drops of light machine oil.

Check all adjustments after lubricating.

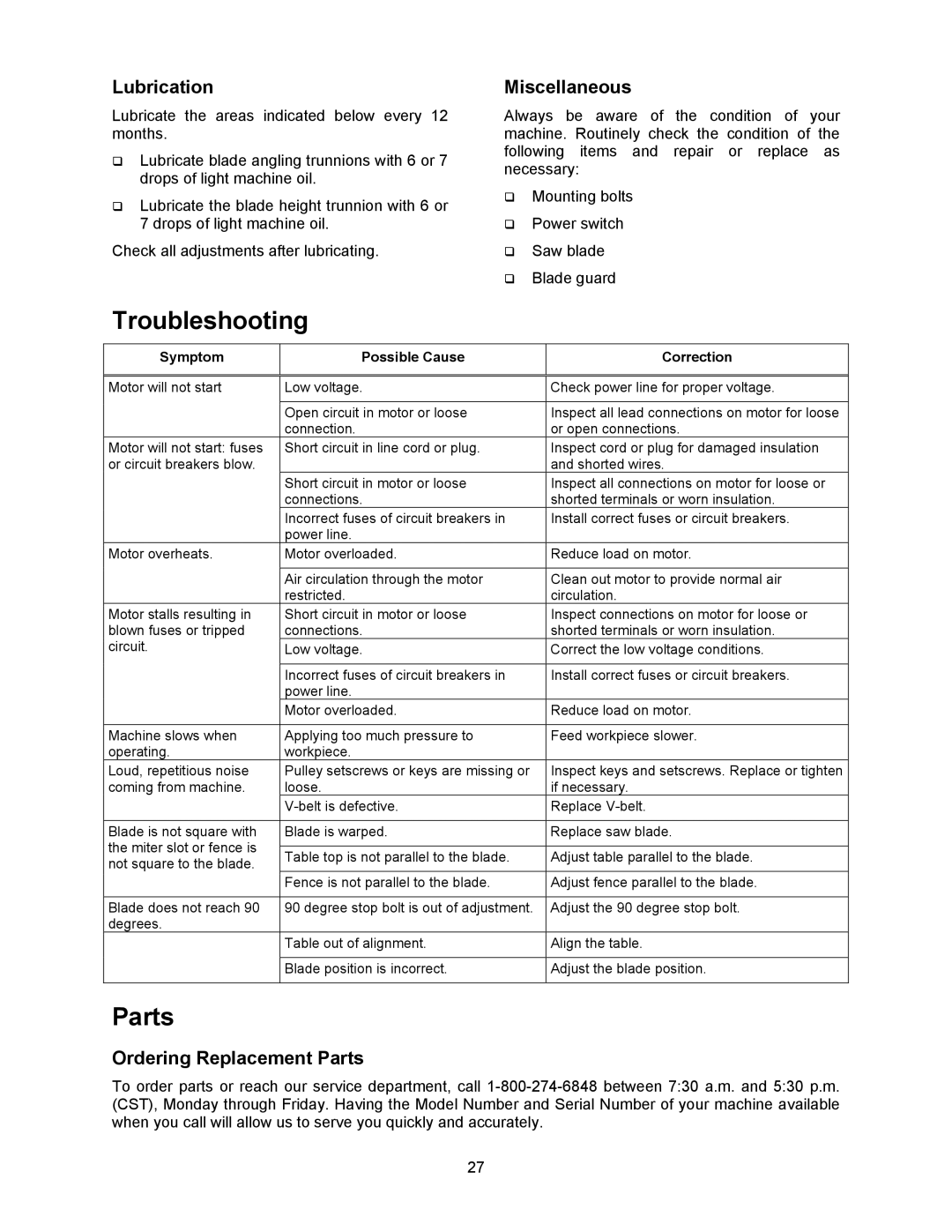

Troubleshooting

Miscellaneous

Always be aware of the condition of your machine. Routinely check the condition of the following items and repair or replace as necessary:

Mounting bolts

Power switch

Saw blade

Blade guard

Symptom | Possible Cause | Correction | |

|

|

| |

Motor will not start | Low voltage. | Check power line for proper voltage. | |

|

|

| |

| Open circuit in motor or loose | Inspect all lead connections on motor for loose | |

| connection. | or open connections. | |

Motor will not start: fuses | Short circuit in line cord or plug. | Inspect cord or plug for damaged insulation | |

or circuit breakers blow. |

| and shorted wires. | |

| Short circuit in motor or loose | Inspect all connections on motor for loose or | |

| connections. | shorted terminals or worn insulation. | |

| Incorrect fuses of circuit breakers in | Install correct fuses or circuit breakers. | |

| power line. |

| |

Motor overheats. | Motor overloaded. | Reduce load on motor. | |

|

|

| |

| Air circulation through the motor | Clean out motor to provide normal air | |

| restricted. | circulation. | |

Motor stalls resulting in | Short circuit in motor or loose | Inspect connections on motor for loose or | |

blown fuses or tripped | connections. | shorted terminals or worn insulation. | |

circuit. | Low voltage. | Correct the low voltage conditions. | |

|

|

| |

| Incorrect fuses of circuit breakers in | Install correct fuses or circuit breakers. | |

| power line. |

| |

| Motor overloaded. | Reduce load on motor. | |

|

|

| |

Machine slows when | Applying too much pressure to | Feed workpiece slower. | |

operating. | workpiece. |

| |

Loud, repetitious noise | Pulley setscrews or keys are missing or | Inspect keys and setscrews. Replace or tighten | |

coming from machine. | loose. | if necessary. | |

| Replace | ||

|

|

| |

Blade is not square with | Blade is warped. | Replace saw blade. | |

the miter slot or fence is |

|

| |

Table top is not parallel to the blade. | Adjust table parallel to the blade. | ||

not square to the blade. | |||

|

| ||

| Fence is not parallel to the blade. | Adjust fence parallel to the blade. | |

|

|

| |

Blade does not reach 90 | 90 degree stop bolt is out of adjustment. | Adjust the 90 degree stop bolt. | |

degrees. |

|

| |

| Table out of alignment. | Align the table. | |

|

|

| |

| Blade position is incorrect. | Adjust the blade position. | |

|

|

|

Parts

Ordering Replacement Parts

To order parts or reach our service department, call

27