Figure 39

Safety Devices

Feather Board

The feather board (Figure 40) should be made of straight grain hardwood approximately 1" thick and 4" to 8" wide depending on the size of the machine. The length is developed in accordance with intended use. Feather boards can be fastened to the table or rip fence by use of

Figure 40

Push Stick

A push stick is provided with this saw and should be used as an added level of safety for the operator.

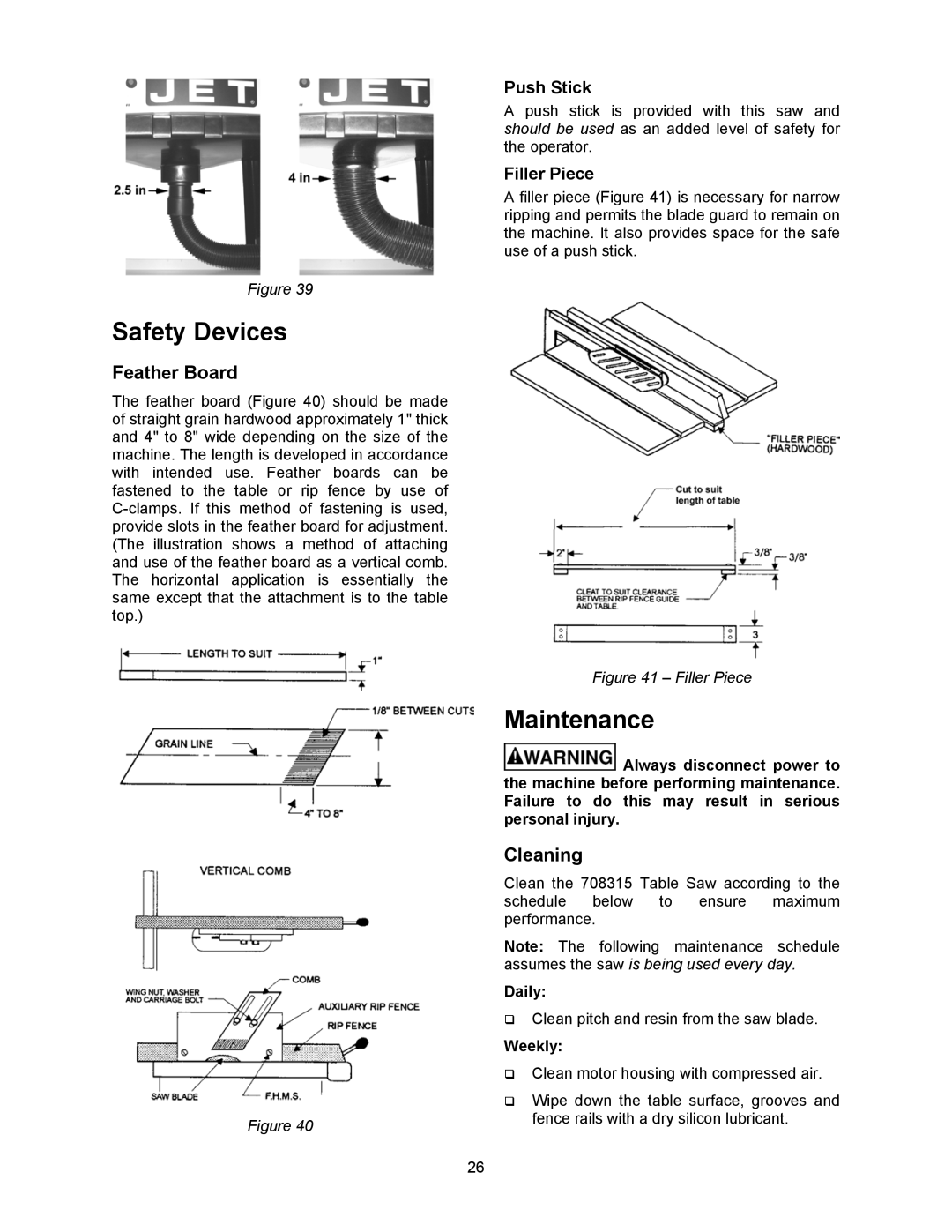

Filler Piece

A filler piece (Figure 41) is necessary for narrow ripping and permits the blade guard to remain on the machine. It also provides space for the safe use of a push stick.

Figure 41 – Filler Piece

Maintenance

![]() Always disconnect power to the machine before performing maintenance. Failure to do this may result in serious personal injury.

Always disconnect power to the machine before performing maintenance. Failure to do this may result in serious personal injury.

Cleaning

Clean the 708315 Table Saw according to the schedule below to ensure maximum performance.

Note: The following maintenance schedule assumes the saw is being used every day.

Daily:

Clean pitch and resin from the saw blade.

Weekly:

Clean motor housing with compressed air.

Wipe down the table surface, grooves and fence rails with a dry silicon lubricant.

26