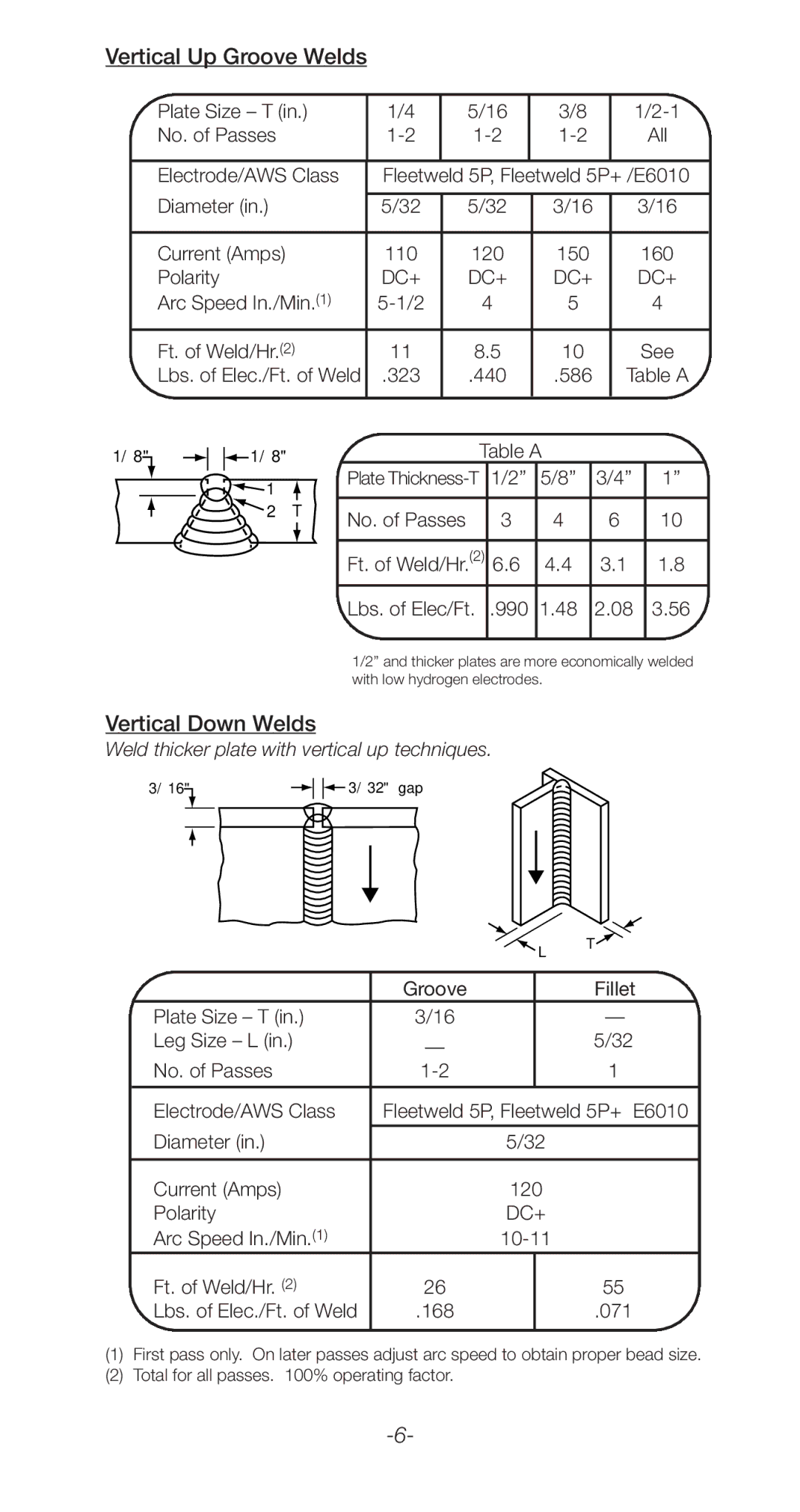

Vertical Up Groove Welds

Plate Size – T (in.) No. of Passes

1/4

5/16

3/8

All

Electrode/AWS Class | Fleetweld 5P, Fleetweld 5P+ /E6010 | |||

Diameter (in.) |

|

|

|

|

5/32 | 5/32 | 3/16 | 3/16 | |

|

|

|

|

|

Current (Amps) | 110 | 120 | 150 | 160 |

Polarity | DC+ | DC+ | DC+ | DC+ |

Arc Speed In./Min.(1) | 4 | 5 | 4 | |

|

|

|

|

|

Ft. of Weld/Hr.(2) | 11 | 8.5 | 10 | See |

Lbs. of Elec./Ft. of Weld | .323 | .440 | .586 | Table A |

|

|

|

|

|

1/8"

1/8" |

|

|

|

| Table A |

|

|

| |

1 |

|

|

| Plate | 1/2” | 5/8” | 3/4” | 1” |

|

2 | T | No. of Passes | 3 | 4 | 6 | 10 |

| ||

|

|

|

|

| |||||

|

|

|

| Ft. of Weld/Hr.(2) 6.6 | 4.4 | 3.1 | 1.8 |

| |

Lbs. of Elec/Ft.

.990 1.48

2.08

3.56

1/2” and thicker plates are more economically welded with low hydrogen electrodes.

Vertical Down Welds

Weld thicker plate with vertical up techniques.

3/16" |

|

|

|

|

|

|

|

| 3/32" gap |

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| L | T |

|

|

|

|

|

|

| |

|

| Groove |

|

| Fillet |

|

|

|

|

|

| ||

| Plate Size – T (in.) | 3/16 |

|

| — |

|

| Leg Size – L (in.) | — |

|

| 5/32 |

|

|

|

|

|

|

| |

| No. of Passes |

|

| 1 |

| |

|

|

|

|

| ||

| Electrode/AWS Class | Fleetweld 5P, Fleetweld 5P+ E6010 |

| |||

|

|

|

|

|

| |

| Diameter (in.) |

| 5/32 |

|

| |

|

|

|

|

|

|

|

| Current (Amps) |

| 120 |

|

| |

| Polarity |

| DC+ |

|

| |

| Arc Speed In./Min.(1) |

|

|

| ||

| Ft. of Weld/Hr. (2) | 26 |

|

| 55 |

|

| Lbs. of Elec./Ft. of Weld | .168 |

|

| .071 |

|

|

|

|

|

|

|

|

(1)First pass only. On later passes adjust arc speed to obtain proper bead size.

(2)Total for all passes. 100% operating factor.