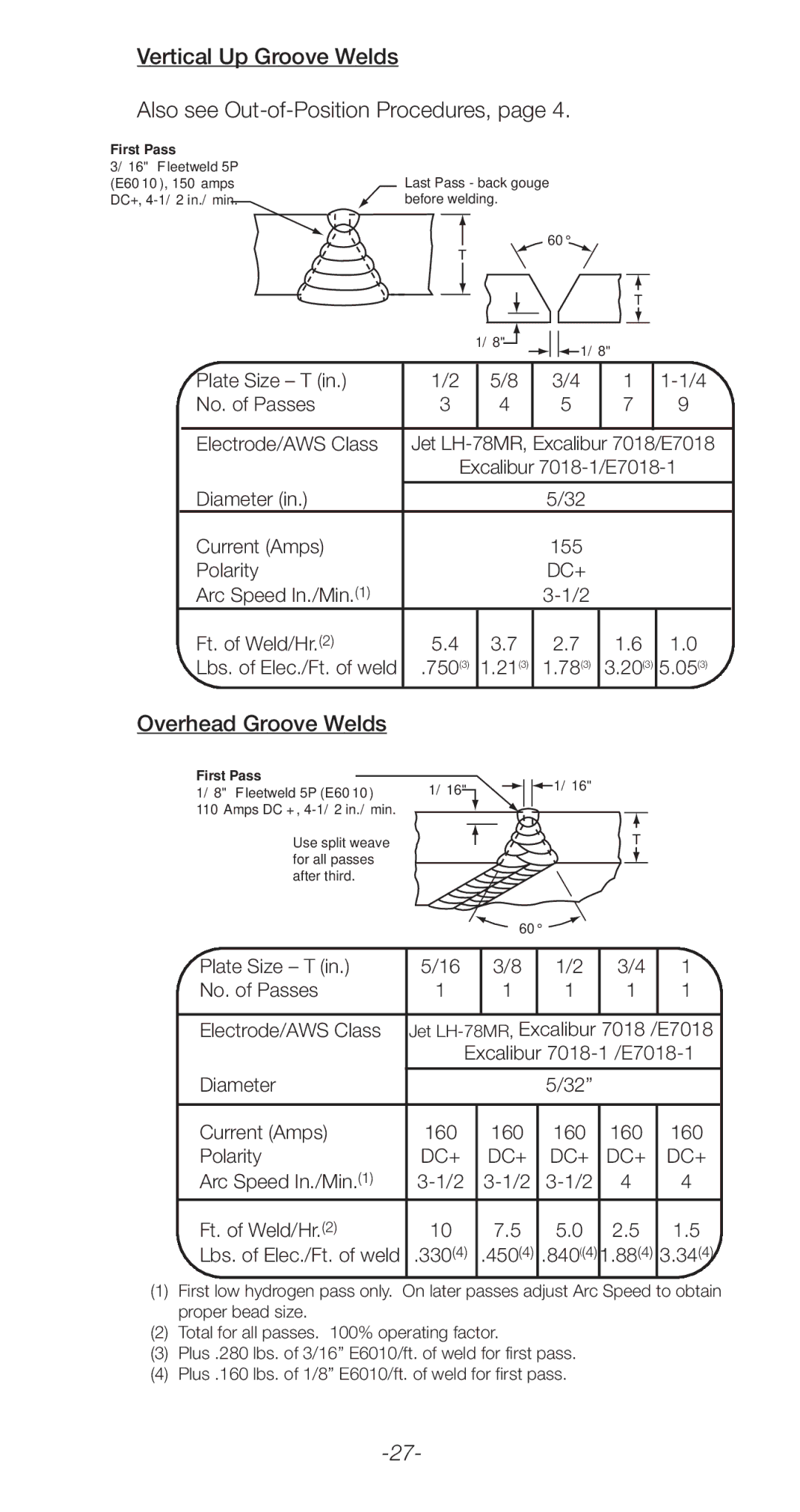

Vertical Up Groove Welds

Also see

First Pass

3/16" Fleetweld 5P (E6010), 150 amps DC+,

Last Pass - back gouge before welding.

T

1/8"

60°

T

![]()

![]() 1/8"

1/8"

| Plate Size – T (in.) | 1/2 | 5/8 | 3/4 | 1 |

| |

| No. of Passes | 3 | 4 | 5 | 7 | 9 |

|

|

|

|

|

|

|

|

|

| Electrode/AWS Class | Jet | |||||

|

| Excalibur | |||||

|

|

|

|

|

|

|

|

| Diameter (in.) |

|

| 5/32 |

|

|

|

| Current (Amps) |

|

| 155 |

|

|

|

| Polarity |

|

| DC+ |

|

|

|

| Arc Speed In./Min.(1) |

|

|

|

|

| |

| Ft. of Weld/Hr.(2) | 5.4 | 3.7 | 2.7 | 1.6 | 1.0 |

|

| Lbs. of Elec./Ft. of weld | .750(3) | 1.21(3) | 1.78(3) | 3.20(3) | 5.05(3) |

|

|

|

|

|

|

|

|

|

Overhead Groove Welds

First Pass | 1/16" |

1/8" Fleetweld 5P (E6010) |

110 Amps DC +,

Use split weave for all passes after third.

![]()

![]()

![]() 1/16"

1/16"

T

60°

Plate Size – T (in.) | 5/16 | 3/8 | 1/2 | 3/4 | 1 |

No. of Passes | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

|

Electrode/AWS Class | Jet | ||||

| Excalibur | ||||

|

|

|

|

|

|

Diameter |

|

| 5/32” |

|

|

|

|

|

|

|

|

Current (Amps) | 160 | 160 | 160 | 160 | 160 |

Polarity | DC+ | DC+ | DC+ | DC+ | DC+ |

Arc Speed In./Min.(1) | 4 | 4 | |||

Ft. of Weld/Hr.(2) | 10 | 7.5 | 5.0 | 2.5 | 1.5 |

Lbs. of Elec./Ft. of weld | .330(4) | .450(4) | .840((4) | 1.88(4) | 3.34(4) |

(1)First low hydrogen pass only. On later passes adjust Arc Speed to obtain proper bead size.

(2)Total for all passes. 100% operating factor.

(3)Plus .280 lbs. of 3/16” E6010/ft. of weld for first pass.

(4)Plus .160 lbs. of 1/8” E6010/ft. of weld for first pass.