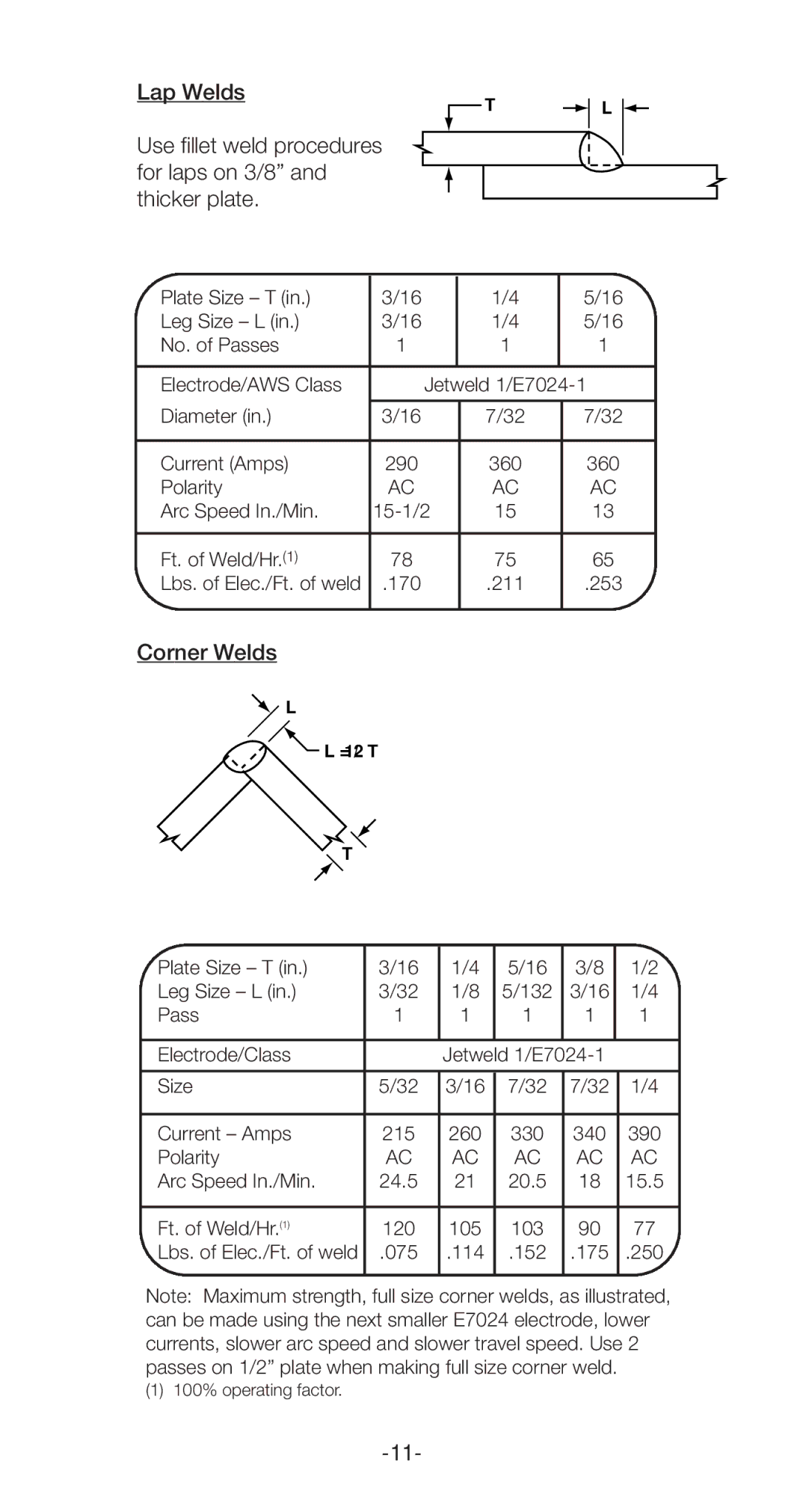

Lap Welds

T

Use fillet weld procedures for laps on 3/8” and thicker plate.

L ![]()

Plate Size – T (in.) | 3/16 | 1/4 | 5/16 | ||

Leg Size – L (in.) | 3/16 | 1/4 | 5/16 | ||

No. of Passes | 1 | 1 | 1 | ||

|

|

|

|

|

|

Electrode/AWS Class | Jetweld | ||||

|

|

|

|

|

|

Diameter (in.) | 3/16 |

| 7/32 |

| 7/32 |

|

|

|

|

|

|

Current (Amps) | 290 |

| 360 |

| 360 |

Polarity | AC |

| AC |

| AC |

Arc Speed In./Min. |

| 15 |

| 13 | |

|

|

|

|

|

|

Ft. of Weld/Hr.(1) | 78 |

| 75 |

| 65 |

Lbs. of Elec./Ft. of weld | .170 |

| .211 |

| .253 |

|

|

|

|

|

|

Corner Welds

L

![]() L = 1/2 T

L = 1/2 T

T

Plate Size – T (in.) | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 |

Leg Size – L (in.) | 3/32 | 1/8 | 5/132 | 3/16 | 1/4 |

Pass | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

|

Electrode/Class |

| Jetweld |

| ||

|

|

|

|

|

|

Size | 5/32 | 3/16 | 7/32 | 7/32 | 1/4 |

|

|

|

|

|

|

Current – Amps | 215 | 260 | 330 | 340 | 390 |

Polarity | AC | AC | AC | AC | AC |

Arc Speed In./Min. | 24.5 | 21 | 20.5 | 18 | 15.5 |

|

|

|

|

|

|

Ft. of Weld/Hr.(1) | 120 | 105 | 103 | 90 | 77 |

Lbs. of Elec./Ft. of weld | .075 | .114 | .152 | .175 | .250 |

|

|

|

|

|

|

Note: Maximum strength, full size corner welds, as illustrated, can be made using the next smaller E7024 electrode, lower currents, slower arc speed and slower travel speed. Use 2 passes on 1/2” plate when making full size corner weld.

(1) 100% operating factor.