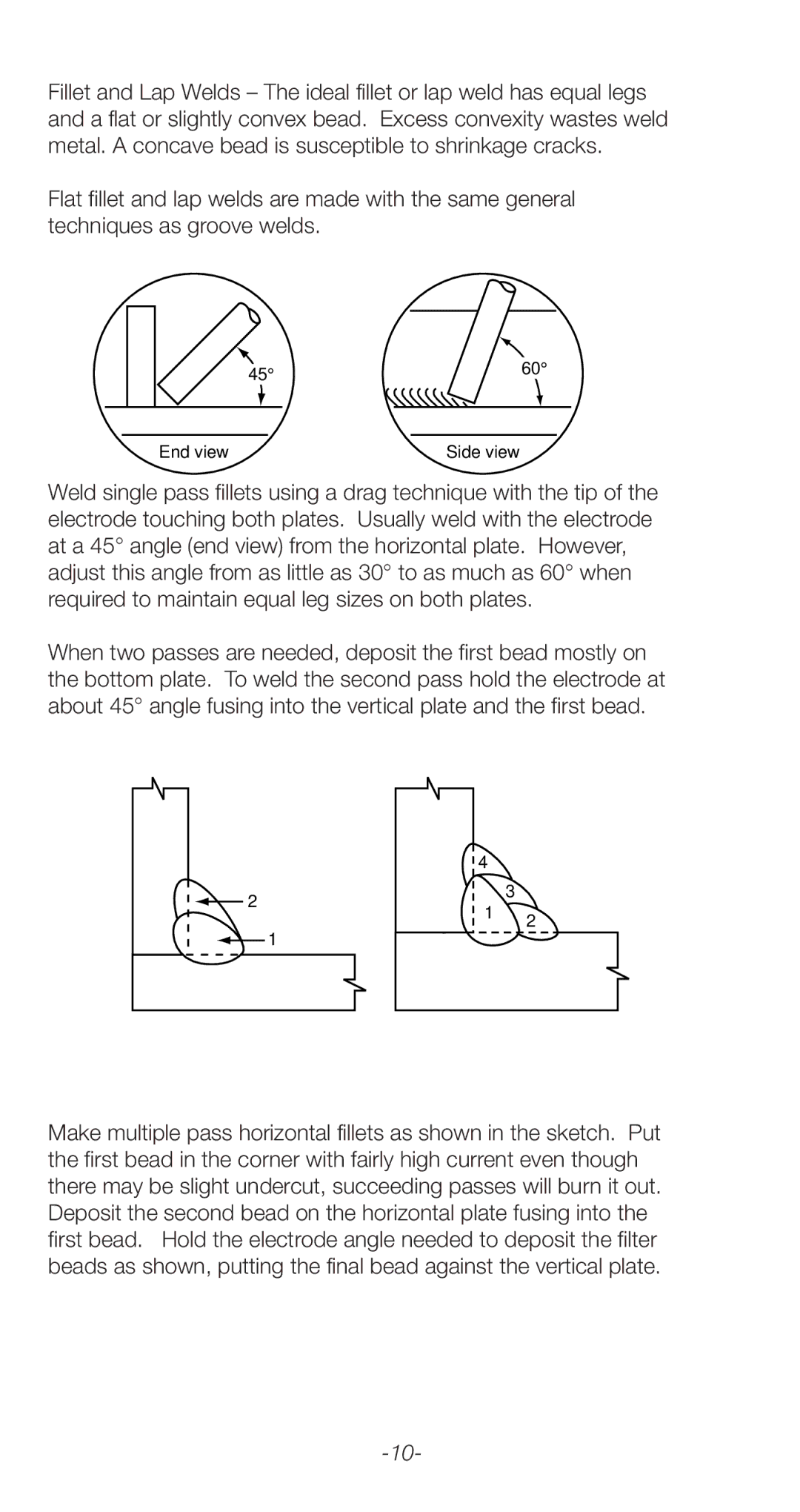

Fillet and Lap Welds – The ideal fillet or lap weld has equal legs and a flat or slightly convex bead. Excess convexity wastes weld metal. A concave bead is susceptible to shrinkage cracks.

Flat fillet and lap welds are made with the same general techniques as groove welds.

| 45° | 60° |

|

| |

End view |

| Side view |

Weld single pass fillets using a drag technique with the tip of the electrode touching both plates. Usually weld with the electrode at a 45° angle (end view) from the horizontal plate. However, adjust this angle from as little as 30° to as much as 60° when required to maintain equal leg sizes on both plates.

When two passes are needed, deposit the first bead mostly on the bottom plate. To weld the second pass hold the electrode at about 45° angle fusing into the vertical plate and the first bead.

| 4 |

| |

2 |

| 3 | |

1 | 2 | ||

| |||

| 1 | ||

|

|

Make multiple pass horizontal fillets as shown in the sketch. Put the first bead in the corner with fairly high current even though there may be slight undercut, succeeding passes will burn it out. Deposit the second bead on the horizontal plate fusing into the first bead. Hold the electrode angle needed to deposit the filter beads as shown, putting the final bead against the vertical plate.