Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

|

|

|

| ELECTRICAL DIAGRAMS |

|

|

| ||||||

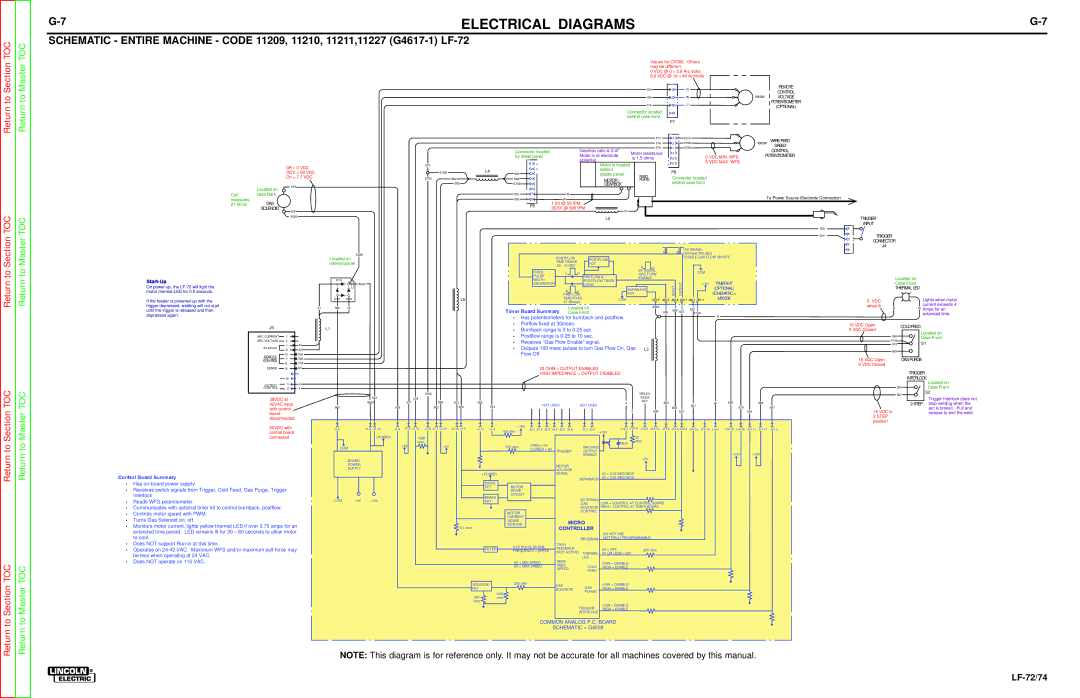

SCHEMATIC - ENTIRE MACHINE - CODE 11209, 11210, 11211,11227 |

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

| Values for CV300. Others |

|

| ||

|

|

|

|

|

|

|

|

| may be different. |

|

|

| |

|

|

|

|

|

|

|

|

| 0 VDC @ 0 = 5.8 Arc Volts |

|

| ||

|

|

|

|

|

|

|

|

| 6.6 VDC @ 10 = 40 ArcVolts |

|

| ||

|

|

|

|

|

|

|

|

| 75A | 1 | 75 |

| REMOTE |

|

|

|

|

|

|

|

|

|

| CONTROL | |||

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| 76A | 2 | 76 | 10K/2W | VOLTAGE |

|

|

|

|

|

|

|

|

| 77A | 3 | 77 |

| POTENTIOMETER |

|

|

|

|

|

|

|

|

|

| (OPTIONAL) | |||

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| Connector located | 4 |

|

|

|

|

|

|

|

|

|

|

|

| behind case front |

|

|

|

|

|

|

|

|

|

|

|

|

|

| P7 |

|

|

|

|

|

|

|

|

|

|

|

| 577 | 3 | 577A |

| WIRE FEED |

|

|

|

|

|

|

|

|

| 576 | 2 | 576A | 10K/2W | |

|

|

|

|

|

|

|

|

| 575 | 1 | 575A |

| SPEED |

|

|

|

|

|

| Connector located | Gearbox ratio is 2:47 |

| CONTROL | ||||

|

|

|

|

|

| Motor resistance | 4 |

|

| ||||

|

|

|

|

|

| by sheet panel | Motor is at electrode | 0 VDC MIN. WFS | POTENTIOMETER | ||||

|

|

|

|

|

| is 1.5 ohms | 5 | ||||||

|

|

|

|

|

| potential |

|

| |||||

|

|

|

|

|

|

| 1 |

| 6 | 5 VDC MAX. WFS |

|

| |

|

|

| 575 |

|

|

| Motor is located |

|

| ||||

|

|

|

|

|

|

|

|

| |||||

|

| Off = 0 VDC |

|

|

|

|

|

|

|

| |||

|

|

|

| L4 |

| 2 | behind |

| P8 |

|

|

| |

|

| OCV = 59 VDC |

| 575B | 563 | 3 | glastic panel |

|

|

|

| ||

|

|

|

| FEED |

|

|

| ||||||

|

| On = 7.7 VDC | 575C | 562 |

| 562 | 4 | MOTOR / | Connector located |

|

| ||

|

|

|

| 563 |

|

|

| PLATE | behind case front |

|

| ||

|

|

|

|

| 575B | 5 | GEARBOX |

|

|

| |||

|

| 553 |

|

|

|

|

|

|

|

| |||

| Located on |

|

|

|

| 6 |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| ||

Coil | case back |

|

|

|

| 551 | 7 | B |

|

|

|

| To Power Source Electrode Connection |

measures |

|

|

|

|

| 550 | 8 | W |

|

|

|

| |

21 ohms | GAS |

|

|

|

|

| P5 | 1.6V @ 50 IPM |

|

|

|

|

|

| SOLENOID |

|

|

|

|

| 30.6V @ 800 IPM |

|

|

|

|

| |

| 552 |

|

|

|

|

| 67 |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| 552B |

|

|

|

|

| L2 |

|

|

|

| TRIGGER |

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| INPUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 556 | A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 554 | B | TRIGGER |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| C |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CONNECTOR |

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| D |

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| J4 |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 15V SIGNAL |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| b |

|

|

|

|

|

|

| E |

|

|

|

| ||

|

|

|

|

|

| 552B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| D 100 msec PULSES |

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| POSTFLOW |

|

|

|

|

|

|

| TOGGLE GAS FLOW ON/OFF |

|

|

|

|

|

|

|

|

| |||||

|

|

|

| Located on |

|

|

|

|

|

|

|

|

|

|

|

|

| POSTFLOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

| internal panel |

|

|

|

|

|

|

|

|

|

|

|

| TIME RANGE | POT. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| .25 - 10 SEC |

|

| A | c |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| FIXED |

| c | D |

|

| 5V SIGNAL |

|

|

| COM |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| GAS FLOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PULSE |

|

|

| PREFLOW & |

| ENABLE |

|

|

|

|

|

|

|

|

|

|

|

| Located on |

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WIDTH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

| + | 552A |

|

|

|

|

|

|

|

|

| GENERATOR |

|

| POSTFLOW TIMER |

|

|

|

|

| OUTPUT | +15V | TIMER KIT |

|

|

|

|

|

| Case Front |

| ||||||

| On |

|

|

|

|

|

|

|

|

|

|

|

|

|

| LOGIC | POT |

|

|

|

| INPUT |

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PREFLOW |

|

|

|

|

| SCHEMATIC = |

|

|

|

|

|

| THERMAL LED |

| |||||||||

| motor thermal LED for 0.5 seconds. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| A | b | BURNBACK |

|

|

|

|

| (OPTIONAL) |

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

| - |

|

|

|

|

|

|

| L5 |

|

|

|

|

|

| TIME FIXED | COM |

|

|

| M20336 |

|

|

|

|

|

|

|

| Lights when motor | |||||||

| If the feeder is |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5 | VDC |

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| AT 30msec |

|

|

|

|

|

|

|

|

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| current exceeds 4 | ||||||

| trigger depressed, welding will not start |

| 41 | 580 | 42 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Located on |

|

|

| 606A |

|

|

|

|

|

|

|

|

|

| when lit | B |

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 601 |

|

|

|

|

|

| W Amps for an | |||||||||||

| until the trigger is released and then |

|

|

|

|

|

|

|

|

|

| Timer Board Summary |

|

|

|

|

| 608 |

|

|

|

|

|

|

|

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Case Front |

|

|

|

| 605 | 607 | 515A |

|

|

|

|

|

|

|

|

|

| extended time. | ||||||||

| depressed again. |

|

|

|

|

|

|

|

|

|

|

|

|

| • Has potentiometers for burnback and postflow. |

|

|

|

|

|

|

| B |

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

| J6 |

|

| L1 |

|

|

|

|

|

|

|

|

|

| • | Preflow fixed at 30msec. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 15 VDC Open | COLD FEED |

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

| • Burnback range is 0 to 0.25 sec. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 0 VDC Closed |

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Located on | |||||||||||

| ARC CURRENT | J |

|

|

|

|

|

|

|

|

|

|

|

| • Postflow range is 0.25 to 10 sec. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 558 | ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Case Front | |||||||||||

| ARC VOLTAGE | L |

|

|

|

|

|

|

|

|

|

|

|

| • Receives “Gas Flow Enable” signal. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 515A | S1 | |||||||

|

| I | 41 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 515 | |||||||||

| K | 42 |

|

|

|

|

|

|

|

|

|

|

| • Outputs 100 msec pulses to turn Gas Flow On, Gas | L3 |

|

|

|

|

|

|

|

|

|

|

|

|

| 559 |

|

| |||||||||

|

| G | 75A |

|

|

|

|

|

|

|

|

|

|

|

| Flow Off. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| REMOTE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

| VOLTAGE | F | 76A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 15 VDC Open | GAS PURGE |

| ||

| CONTROL | E | 77A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 0 VDC Closed |

|

|

| |||

| SENSE |

| 67 |

|

|

|

|

|

|

|

|

|

|

|

|

| 20 OHM = OUTPUT ENABLED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

| N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TRIGGER | ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HIGH IMPEDANCE = OUTPUT DISABLED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

| M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| INTERLOCK | |

| OUTPUT | C | 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Located on |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 589 |

| Case Front | |||

| CONTROL | D | 4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| 575C |

|

|

|

|

|

|

|

|

|

|

|

| MOLEX |

|

|

|

|

|

|

|

|

|

|

|

|

| 587 |

| S2 |

|

|

|

|

|

|

|

| 552 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| INDEX |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Trigger Interlock does not | |

| 38VDC at |

|

|

|

|

|

| 576 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

| 552A |

| 563 |

|

|

|

|

|

|

|

|

|

|

|

| KEY |

|

|

|

|

|

| 558 |

|

|

|

|

|

|

|

| |||||

| 42VAC input |

|

|

|

|

| 577 | 551 | 556 |

|

|

|

|

|

|

|

| 4 |

|

| 605 |

|

|

| W |

|

| 589 |

|

|

|

| stop welding when the | |||||||

|

|

|

|

|

|

|

|

| NOT USED |

| NOT USED |

|

|

|

|

| 601 |

|

|

|

|

|

| |||||||||||||||||

|

|

|

|

|

|

|

|

|

| 550 |

| 554 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

| with control |

| 580 |

|

|

|

| 553 |

| 562 |

|

|

|

|

|

|

|

| 2 |

|

| 606 |

| 608 | 607 |

|

|

| 515 | 559 |

| 587 |

| 15 VDC in |

| arc is broken. Pull and | ||||

| board |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| release to end the weld. | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

| disconnected. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2 STEP |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| position |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 60VDC with |

|

|

| +15V |

|

|

|

|

| ||||||||||||||||||||||||||||||

| control board |

|

|

|

|

|

|

|

|

|

|

|

| 750 ohm |

|

|

|

|

| +15V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| connected |

|

|

|

|

| +POWER |

| 100K |

|

|

|

|

|

|

|

|

|

|

| 20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| ohm |

|

|

|

|

|

| OPEN = 0V |

|

|

|

| MOV | ohm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| +5V | +5V |

|

|

| 750 ohm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

| COM |

|

|

|

|

|

|

|

|

|

|

| MACHINE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CLOSED = 8V | TRIGGER | OUTPUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| +15V | +15V |

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ENABLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

| BOARD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| +5V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| POWER |

|

|

|

|

|

|

|

|

|

|

|

| MOTOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| SUPPLY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| VOLTAGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Control Board Summary |

|

|

|

|

|

|

|

|

|

|

| + POWER |

|

|

| SENSE |

| 0V = 0.02 SECONDS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| BURNBACK | 5V = 0.25 SECONDS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

• Has |

|

|

|

|

|

|

|

|

|

|

|

| DRIVE | MOTOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

• Receives switch signals from Trigger, Cold Feed, Gas Purge, Trigger |

|

|

|

|

|

|

|

|

|

|

| FET |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| DRIVE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

| Interlock |

|

|

|

|

|

|

|

|

|

|

|

| BRAKE | CIRCUIT |

|

|

|

| EXTERNAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

• | Reads WFS potentiometer. |

|

| COM |

| +5V | +15V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| FET |

|

|

|

|

|

| LOW = CONTROL AT CONTROL BOARD |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| GAS |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

• Communicates with optional timer kit to control burnback, postflow. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SOLENOID HIGH = CONTROL AT TIMER BOARD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

• Controls motor speed with PWM. |

|

|

|

|

|

|

|

|

|

|

|

|

| MOTOR |

|

|

|

|

| CONTROL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

• Turns Gas Solenoid on, off. |

|

|

|

|

|

|

|

|

|

|

|

|

| CURRENT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| SENSE |

|

|

|

| MICRO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

• Monitors motor current, lights yellow thermal LED if over 3.75 amps for an |

|

|

|

|

|

|

|

|

|

|

|

| SCALING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

| 0.1 ohm |

|

|

|

|

|

| CONTROLLER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

| extended time period. LED remains lit for 30 – 60 seconds to allow motor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| DO NOT USE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| to cool. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PROGRAM | NOT FIELD PROGRAMMABLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

• Does NOT support |

|

|

|

|

|

|

|

|

|

|

|

|

|

| TACH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

• | Operates on |

|

|

|

|

|

|

|

|

|

|

| FILTER |

| FEEDBACK |

| 5V = OFF |

| 200 ohm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| FREQUENCY = SPEED |

| (NOT ACTIVE) THERMAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

| be less when operating at 24 VAC. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4V OR LESS = ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

• Does NOT operate on 115 VAC. |

|

|

|

|

|

|

|

|

|

|

|

|

| 0V = MIN SPEED |

|

|

| LOW = DISABLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| WIRE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5V = MAX SPEED |

| FEED |

| COLD | HIGH = ENABLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SPEED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| FEED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| SOLENOID | 200 ohm |

|

| GAS |

|

| LOW = DISABLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| FET |

|

|

|

|

|

| GAS | HIGH = ENABLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SOLENOID |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PURGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 0.25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| 10K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ohm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| ohm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TRIGGER | LOW = DISABLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HIGH = ENABLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| INTERLOCK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COMMON ANALOG P.C. BOARD

SCHEMATIC = G4559

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.