Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

ROTOR VOLTAGE TEST (continued)

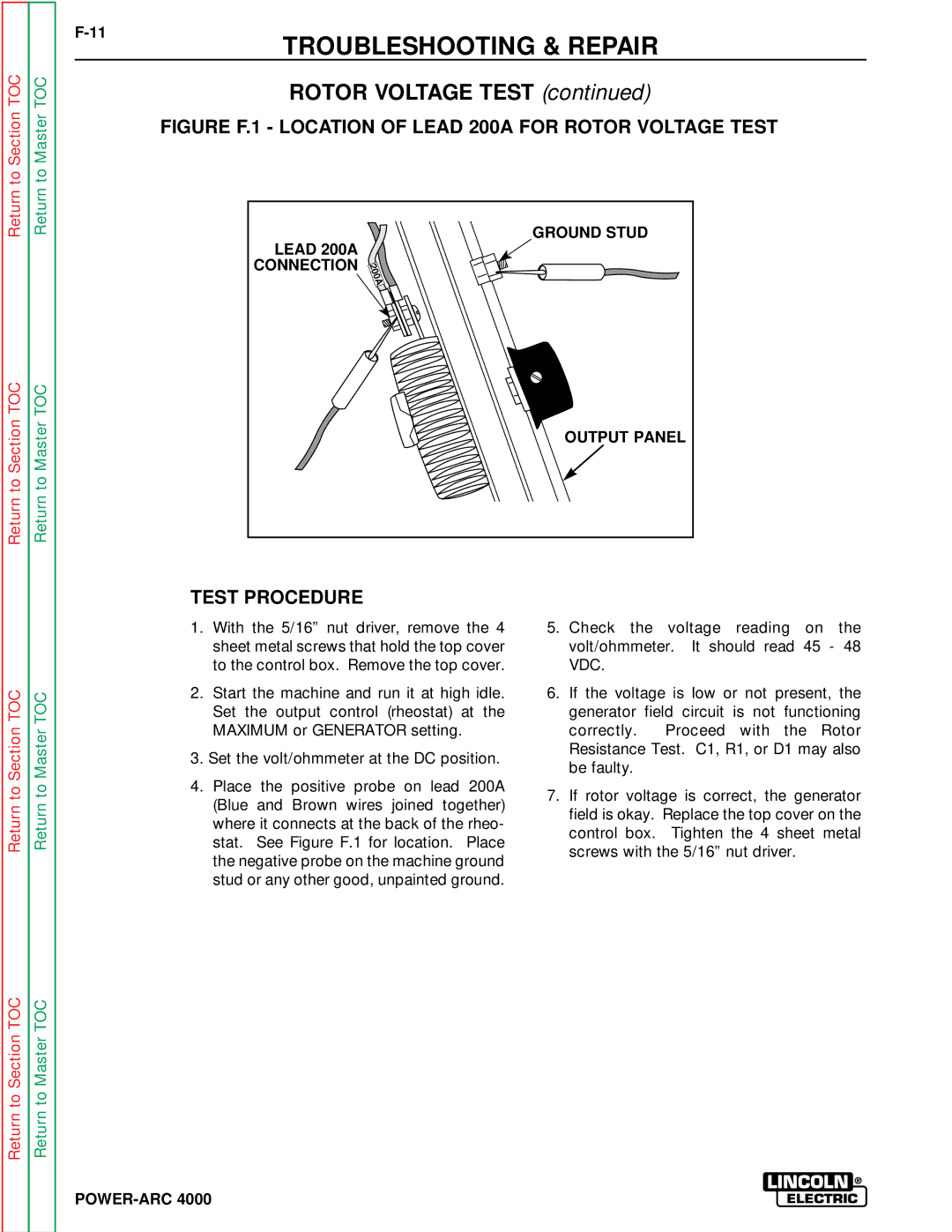

FIGURE F.1 - LOCATION OF LEAD 200A FOR ROTOR VOLTAGE TEST

GROUND STUD

LEAD 200A

CONNECTION

OUTPUT PANEL

TEST PROCEDURE

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

1.With the 5/16” nut driver, remove the 4 sheet metal screws that hold the top cover to the control box. Remove the top cover.

2.Start the machine and run it at high idle. Set the output control (rheostat) at the MAXIMUM or GENERATOR setting.

3.Set the volt/ohmmeter at the DC position.

4.Place the positive probe on lead 200A (Blue and Brown wires joined together) where it connects at the back of the rheo- stat. See Figure F.1 for location. Place the negative probe on the machine ground stud or any other good, unpainted ground.

5.Check the voltage reading on the volt/ohmmeter. It should read 45 - 48 VDC.

6.If the voltage is low or not present, the generator field circuit is not functioning correctly. Proceed with the Rotor Resistance Test. C1, R1, or D1 may also be faulty.

7.If rotor voltage is correct, the generator field is okay. Replace the top cover on the control box. Tighten the 4 sheet metal screws with the 5/16” nut driver.