Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

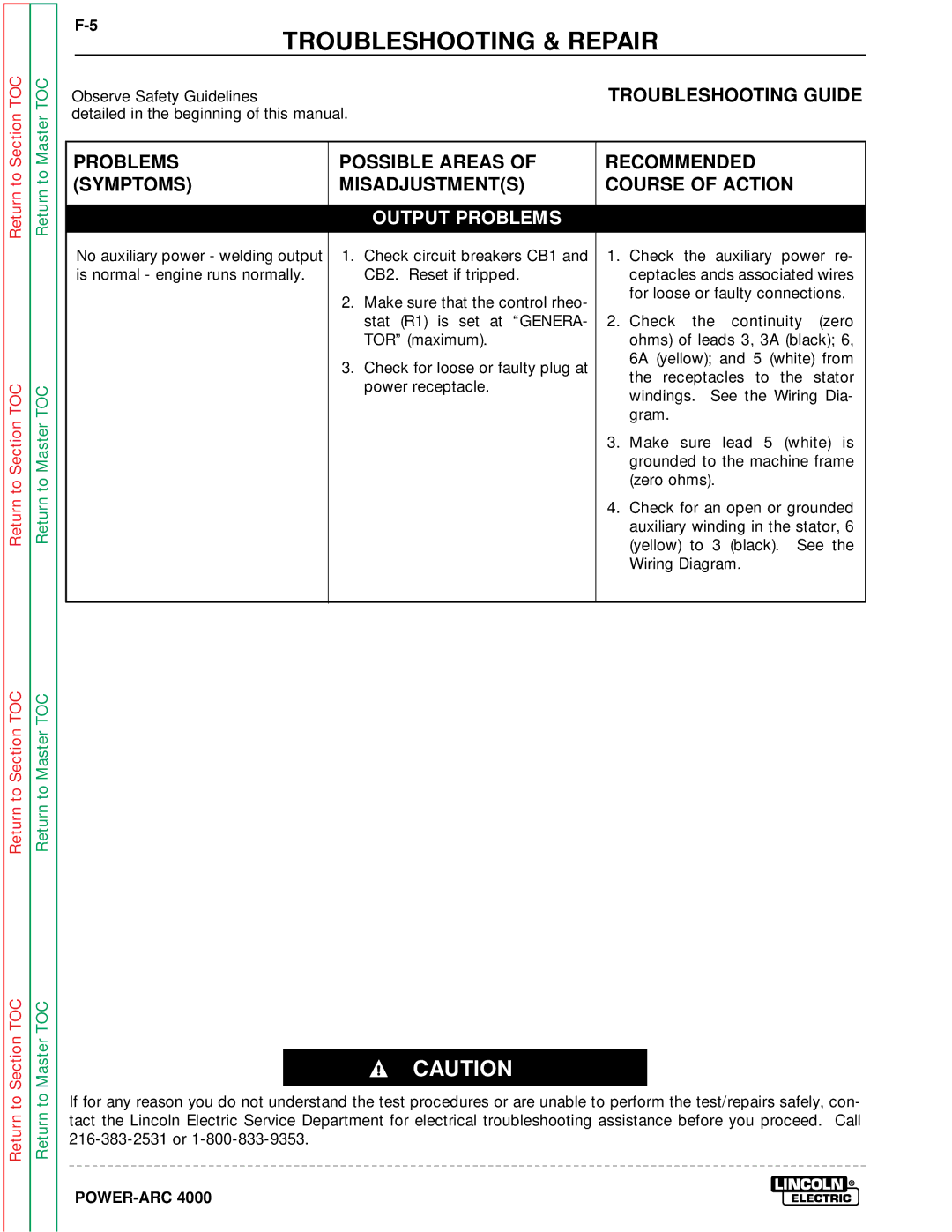

TROUBLESHOOTING & REPAIR

Observe Safety Guidelines |

| TROUBLESHOOTING GUIDE |

detailed in the beginning of this manual. |

| |

|

|

|

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION |

|

|

|

| OUTPUT PROBLEMS |

|

No auxiliary power - welding output | 1. Check circuit breakers CB1 and | 1. Check the auxiliary power re- |

is normal - engine runs normally. | CB2. Reset if tripped. | ceptacles ands associated wires |

| 2. Make sure that the control rheo- | for loose or faulty connections. |

|

| |

| stat (R1) is set at “GENERA- | 2. Check the continuity (zero |

| TOR” (maximum). | ohms) of leads 3, 3A (black); 6, |

| 3. Check for loose or faulty plug at | 6A (yellow); and 5 (white) from |

| the receptacles to the stator | |

| power receptacle. | |

| windings. See the Wiring Dia- | |

|

| |

|

| gram. |

|

| 3. Make sure lead 5 (white) is |

|

| grounded to the machine frame |

|

| (zero ohms). |

|

| 4. Check for an open or grounded |

|

| auxiliary winding in the stator, 6 |

|

| (yellow) to 3 (black). See the |

|

| Wiring Diagram. |

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call