OPERATION |

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

9.When no more welding is to be done, close valve on gas cylinder (if used), momentarily operate gun trigger to release gas pressure, and turn off POWER MIG® 215.

NOTE: When using Innershield electrode, the gas nozzle may be removed from the insulation on the end of the gun and replaced with the gas- less nozzle. This will give improved visibility and eliminate the possibility of the gas nozzle overheating.

AVOIDING WIRE FEEDING

PROBLEMS

Wire feeding problems can be avoided by observing the following gun handling procedures:

1.Do not kink or pull cable around sharp corners.

2.Keep the gun cable as straight as possible when welding or loading electrode through cable.

3.Do not allow dolly wheels or trucks to run over cables.

4.Keep cable clean by following maintenance instruc- tions.

5.Use only clean,

6.Replace contact tip when the arc starts to become unstable or the contact tip end is fused or deformed.

7.Keep wire reel spindle brake tension to minimum required to prevent excess reel

8.Use proper drive rolls and wire drive idle roll pres- sure for wire size and type being used.

FAN CONTROL

The fan is designed to come on when input power is applied to the POWER MIG® 215 and go off when power is removed.

INPUT LINE VOLTAGE VARIATIONS

High Line Voltage — Higher than rated input voltage will result in output voltages higher than normal for a given tap setting. If your input line is high, you may want to select a lower voltage tap than given on the recommended procedure chart.

Low Line Voltage — You may not be able to get max- imum output from the machine if the line voltage is less than rated input. The unit will continue to weld, but the output may be less than normal for a given tap setting. If your input line is low, you may want to select a high- er voltage tap than given on the recommended proce- dure chart.

WIRE FEED OVERLOAD

PROTECTION

The POWER MIG® has solid state overload protection of the wire drive motor. If the motor becomes over- loaded, the protection circuitry turns off the wire feed speed and gas solenoid. Check for proper size tip, liner, and drive rolls, for any obstructions or bends in the gun cable, and any other factors that would impede the wire feeding. to resume welding, simply pull the trigger. There is no circuit breaker to reset, as the pro- tection is done with reliable solid state electronics.

WELDING THERMAL OVERLOAD PROTECTION

The POWER MIG® 215 has

Return to Section TOC

Return to Master TOC

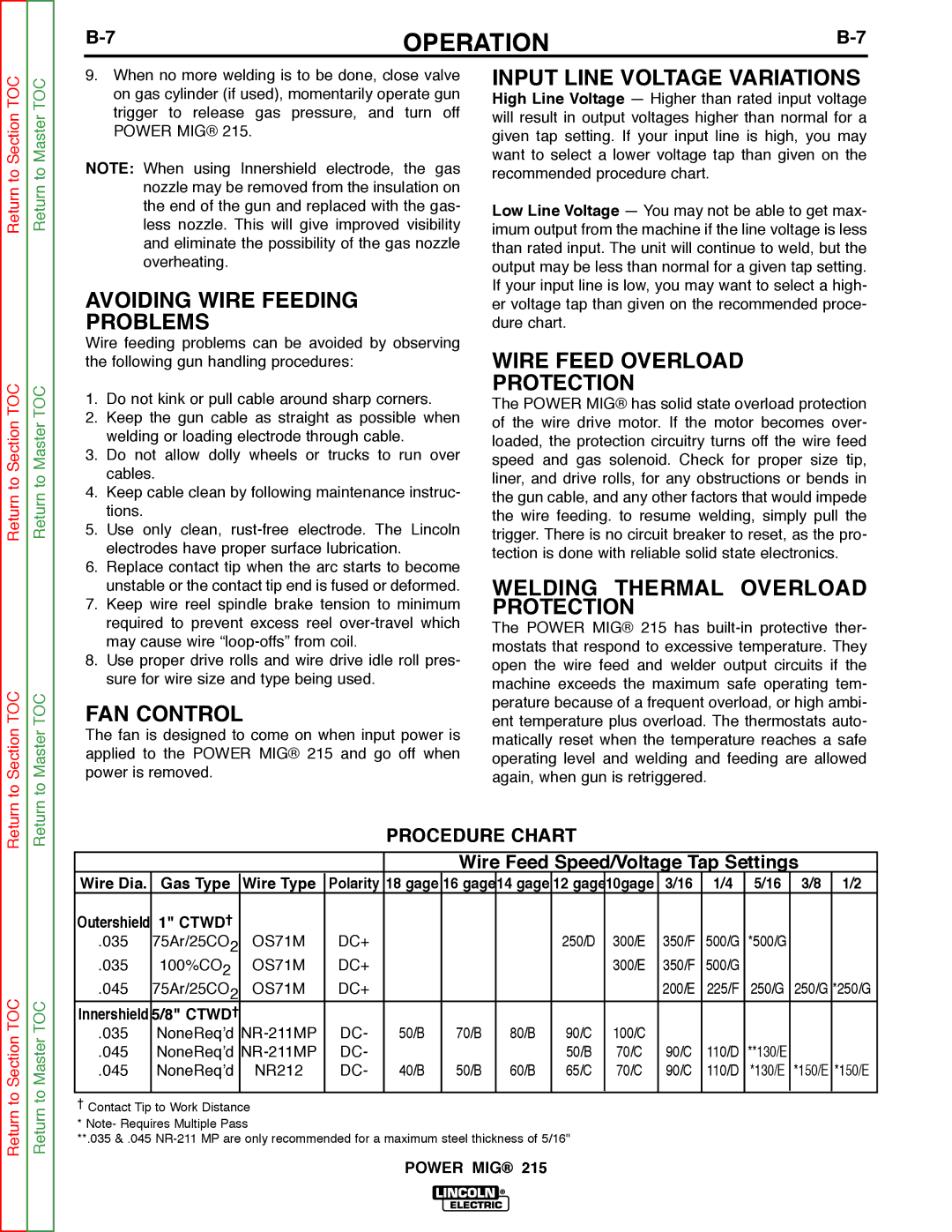

PROCEDURE CHART

|

|

|

|

| Wire Feed Speed/Voltage Tap Settings | ||||||||

Wire Dia. | Gas Type | Wire Type | Polarity | 18 gage | 16 gage14 gage | 12 gage10gage | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | ||

Outershield | 1" CTWD† |

|

|

|

|

|

|

|

|

|

|

|

|

.035 | 75Ar/25CO2 | OS71M | DC+ |

|

|

| 250/D | 300/E | 350/F | 500/G | *500/G |

|

|

.035 | 100%CO2 | OS71M | DC+ |

|

|

|

| 300/E | 350/F | 500/G |

|

|

|

.045 | 75Ar/25CO2 | OS71M | DC+ |

|

|

|

|

| 200/E | 225/F | 250/G | 250/G | *250/G |

Innershield | 5/8" CTWD† |

|

|

|

|

|

|

|

|

|

|

|

|

.035 | NoneReq’d | DC- | 50/B | 70/B | 80/B | 90/C | 100/C |

|

|

|

|

| |

.045 | NoneReq’d | DC- |

|

|

| 50/B | 70/C | 90/C | 110/D | **130/E |

|

| |

.045 | NoneReq’d | NR212 | DC- | 40/B | 50/B | 60/B | 65/C | 70/C | 90/C | 110/D | *130/E | *150/E | *150/E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

†Contact Tip to Work Distance * Note- Requires Multiple Pass

**.035 & .045