Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

| TROUBLESHOOTING AND REPAIR |

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

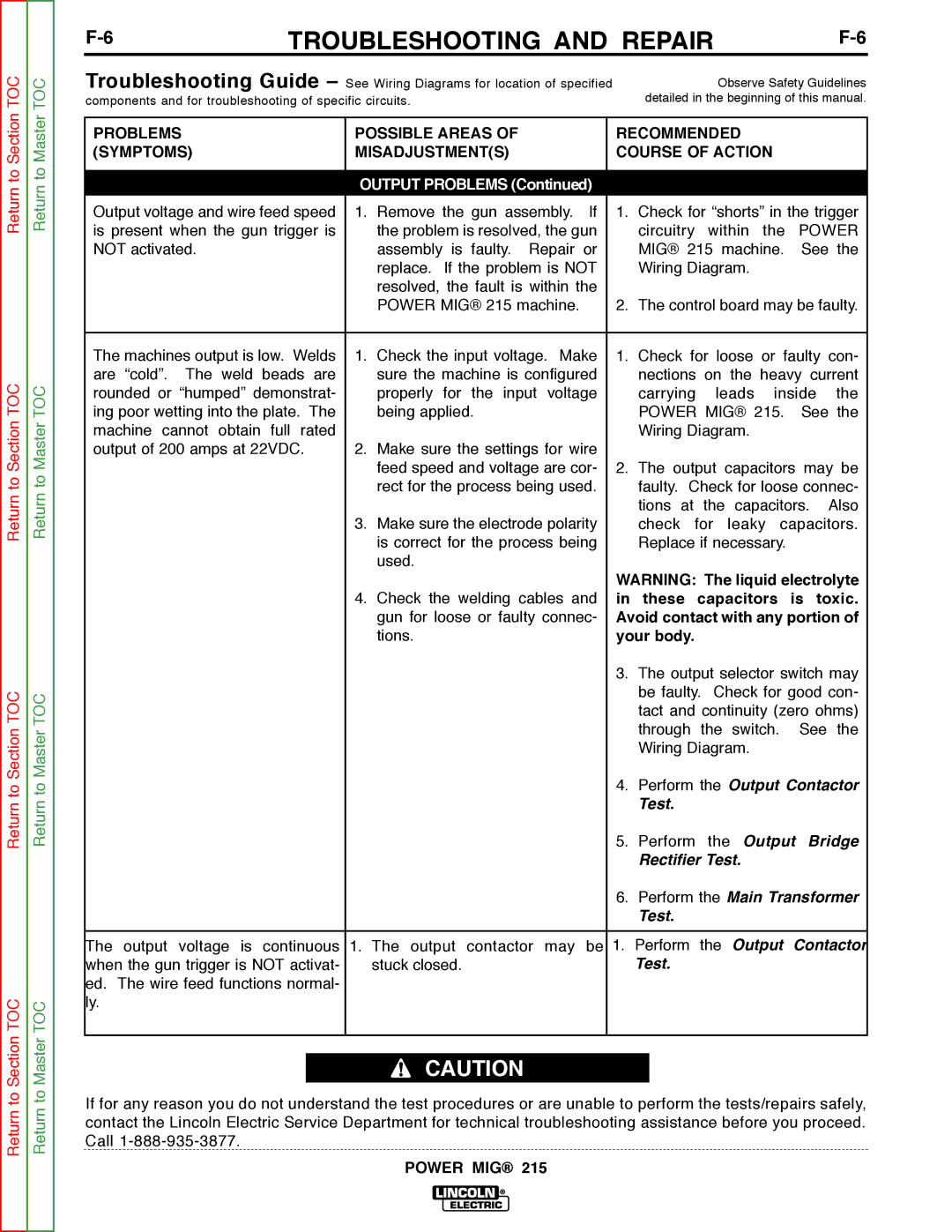

Troubleshooting Guide – See Wiring Diagrams for location of specified |

| Observe Safety Guidelines | |||||||||

components and for troubleshooting of specific circuits. |

|

|

| detailed in the beginning of this manual. | |||||||

|

|

|

|

|

|

|

|

| |||

PROBLEMS |

| POSSIBLE AREAS OF |

|

| RECOMMENDED |

|

| ||||

(SYMPTOMS) |

| MISADJUSTMENT(S) |

|

| COURSE OF ACTION |

|

| ||||

|

|

|

|

|

|

|

|

| |||

|

|

| OUTPUT PROBLEMS (Continued) |

|

|

|

|

| |||

Output voltage and wire feed speed | 1. | Remove the gun assembly. | If |

| 1. Check for “shorts” in the trigger | ||||||

is present when the gun trigger is |

| the problem is resolved, the gun |

| circuitry within the | POWER | ||||||

NOT activated. |

|

| assembly | is faulty. Repair | or |

| MIG® 215 machine. | See the | |||

|

|

|

| replace. | If the problem is NOT |

| Wiring Diagram. |

|

| ||

|

|

|

| resolved, the fault is within the |

|

|

|

|

| ||

|

|

|

| POWER MIG® 215 machine. |

|

| 2. The control board may be faulty. | ||||

|

|

|

|

| |||||||

The machines output is low. Welds | 1. | Check the input voltage. Make |

| 1. Check for loose or faulty con- | |||||||

are “cold”. The | weld beads are |

| sure the machine is configured |

| nections on the heavy current | ||||||

rounded or “humped” demonstrat- |

| properly for the input voltage |

| carrying | leads | inside the | |||||

ing poor wetting into the plate. The |

| being applied. |

|

| POWER MIG® 215. | See the | |||||

machine cannot obtain full rated |

|

|

|

|

| Wiring Diagram. |

|

| |||

output of 200 amps at 22VDC. | 2. | Make sure the settings for wire |

|

|

|

|

| ||||

|

|

|

| feed speed and voltage are cor- |

| 2. The output capacitors may be | |||||

|

|

|

| rect for the process being used. |

| faulty. Check for loose connec- | |||||

|

|

|

|

|

|

|

| tions at the capacitors. Also | |||

|

|

| 3. Make sure the electrode polarity |

| check for | leaky | capacitors. | ||||

|

|

|

| is correct for the process being |

| Replace if necessary. |

| ||||

|

|

|

| used. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WARNING: The liquid electrolyte | |||

|

|

| 4. Check the welding cables and |

| in these capacitors is toxic. | ||||||

|

|

|

| gun for loose or faulty connec- |

| Avoid contact with any portion of | |||||

|

|

|

| tions. |

|

|

| your body. |

|

|

|

|

|

|

|

|

|

|

| 3. The output selector switch may | |||

|

|

|

|

|

|

|

| be faulty. Check for good con- | |||

|

|

|

|

|

|

|

| tact and continuity (zero ohms) | |||

|

|

|

|

|

|

|

| through the switch. See the | |||

|

|

|

|

|

|

|

| Wiring Diagram. |

|

| |

|

|

|

|

|

|

|

| 4. Perform the Output Contactor | |||

|

|

|

|

|

|

|

| Test. |

|

|

|

|

|

|

|

|

|

|

| 5. Perform the Output Bridge | |||

|

|

|

|

|

|

|

| Rectifier Test. |

|

| |

|

|

|

|

|

|

|

| 6. Perform the Main Transformer | |||

|

|

|

|

|

|

|

| Test. |

|

|

|

|

|

| |||||||||

The output voltage is continuous | 1. The output contactor may be | 1. Perform the Output Contactor | |||||||||

when the gun trigger is NOT activat- |

| stuck closed. |

|

| Test. |

|

|

| |||

ed. The wire feed functions normal- |

|

|

|

|

|

|

|

|

| ||

ly. |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call