Section TOC

Master TOC

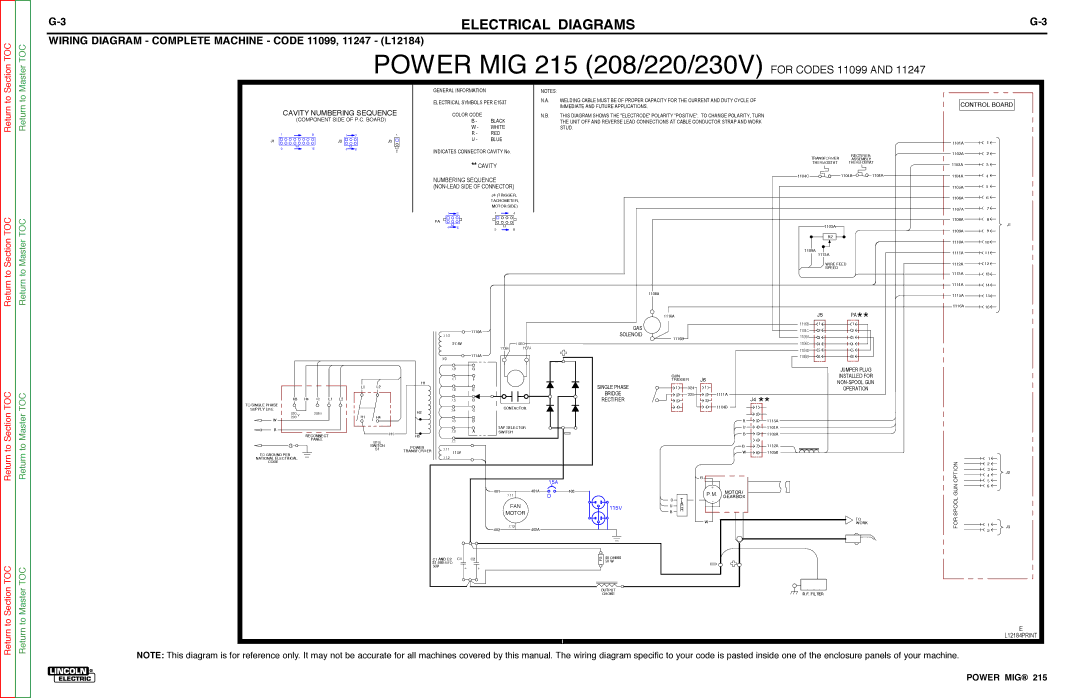

ElEcTrical DiaGramS | ||

WiriNG DiaGram - cOmplETE machiNE - cODE 11099, 11247 - (l12184) |

|

|

POWER MIG 215 (208/220/230V) FOR CODES 11099 AND 11247

Return to

Return to

CAVITY NUMBERING SEQUENCE

(COMPONENT SIDE OF P.C. BOARD)

1 | 8 | 1 | 3 | 1 |

J1 |

| J2 |

| J3 |

9 | 16 | 4 | 6 | 2 |

|

|

|

|

GENERAL INFORMATION

ELECTRICAL SYMBOLS PER E1537

COLOR CODE |

|

B - | BLACK |

W - | WHITE |

R - | RED |

U - | BLUE |

INDICATES CONNECTOR CAVITY No.

**CAVITY

NUMBERING SEQUENCE

(NON-LEAD SIDE OF CONNECTOR)

J4 (TRIGGER,

TACHOMETER,

MOTOR SIDE)

1 | 3 | 1 | 4 |

NOTES: |

|

N.A. | WELDING CABLE MUST BE OF PROPER CAPACITY FOR THE CURRENT AND DUTY CYCLE OF |

| IMMEDIATE AND FUTURE APPLICATIONS. |

N.B. | THIS DIAGRAM SHOWS THE "ELECTRODE" POLARITY “POSITIVE”. TO CHANGE POLARITY, TURN |

| THE UNIT OFF AND REVERSE LEAD CONNECTIONS AT CABLE CONDUCTOR STRAP AND WORK |

| STUD. |

RECTIFIER

TRANSFORMER ASSEMBLY

THERMOSTAT THERMOSTAT

1104C ![]()

![]()

![]() 1104B

1104B![]()

![]()

![]() 1104A

1104A

CONTROL BOARD

1101A ![]() 1

1 ![]()

1102A ![]() 2

2 ![]()

1103A ![]() 3

3 ![]()

1104A ![]() 4

4 ![]()

1105A ![]() 5

5 ![]()

1106A ![]() 6

6 ![]()

1107A ![]() 7

7 ![]()

Return to Master TOC

Return to Master TOC

TOC

PA

4 | 6 | 5 | 8 |

|

|

1110A |

|

X10 |

|

27.8V | 1106C |

1106A | 1107A |

|

|

|

|

|

|

| X9 | 1114A |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| X8 | G |

|

|

|

|

|

|

| H1 | X7 | F |

|

|

|

|

| L1 | L2 |

|

|

| |

|

|

|

|

| X6 | E |

| ||

|

|

|

|

|

|

|

| ||

H3 | H4 | H2 | L1 | L2 |

|

| X5 | D |

|

TO SINGLE PHASE |

|

|

|

|

|

|

|

| CONTACTOR |

SUPPLY LINE |

|

|

|

|

| H2 | X4 | C | |

230220 V |

| 208V |

| H1 | H4 | X3 | B |

| |

W |

|

|

|

|

|

|

| ||

B |

|

|

|

|

|

| X2 | A | TAP SELECTOR |

|

|

|

| H1 |

| SWITCH | |||

| RECONNECT |

|

| H3 | |||||

|

|

|

|

|

| ||||

G |

| PANEL |

|

| LINE |

| X1 |

|

|

|

|

|

| SWITCH | POWER | X11 |

|

| |

|

|

|

|

| S1 | TRANSFORMER |

|

| |

TO GROUND PER |

|

|

|

|

| 115V |

|

| |

|

|

|

|

|

|

|

| ||

NATIONAL ELECTRICAL |

|

|

|

|

|

| X12 |

|

|

CODE |

|

|

|

|

|

|

|

|

|

401 |

|

| 401A |

X11 |

| ||

|

|

|

| FAN |

| MOTOR |

402 | X12 |

402A |

C1 AND C2 C1 |

|

| C2 |

| ||||

31,000 MFD |

|

|

|

|

|

|

|

|

50V |

| + |

|

|

|

| + | |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1103A |

|

|

|

|

|

|

|

|

|

| R2 |

|

|

|

|

|

|

|

| 1109A | 1113A | |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| WIRE FEED |

|

|

|

|

|

|

|

|

|

| SPEED |

|

| 1108A |

|

|

|

|

|

|

|

|

|

| 1116A |

|

|

|

|

|

| J5 | PA |

| GAS |

|

|

|

|

|

| 1116B | 1 | 1 ** |

| SOLENOID |

|

|

|

|

|

| 1104C | 2 | 2 |

| 1116B |

|

|

|

| 1105A | 3 | 3 | ||

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

| 1106C | 4 | 4 |

|

|

|

|

|

|

|

| 1104D | 5 | 5 |

|

|

|

|

|

|

|

| 1105B | 6 | 6 |

|

|

|

|

|

|

|

|

|

| JUMPER PLUG |

|

| GUN |

| J6 |

|

|

|

|

| INSTALLED FOR |

|

| TRIGGER |

|

|

|

|

| |||

SINGLE PHASE |

|

|

|

|

|

|

| |||

1 | 324 | 1 |

|

|

|

|

| OPERATION | ||

| BRIDGE | 2 | 325 | 2 | 1111A | 1 ** |

|

| ||

RECTIFIER | 4 |

| 4 | 1104D |

|

| ||||

3 |

| 3 |

|

| J4 |

|

|

| ||

|

|

|

|

|

|

| 2 |

|

|

|

|

|

|

|

|

| R | 3 | 1115A |

|

|

|

|

|

|

|

| U | 4 | 1101A |

|

|

|

|

|

|

|

| B | 5 | 1102A |

|

|

|

|

|

|

|

|

| 6 | 1112A |

|

|

|

|

|

|

|

| B | 7 |

|

| |

|

|

|

|

|

| W | 8 | 1105B |

|

|

15A |

|

|

| B |

|

|

|

|

|

|

|

|

|

| + |

|

|

|

|

| |

403 |

|

|

|

| MOTOR/ |

|

|

|

| |

|

|

| P.M. |

|

|

|

| |||

D |

| D | T | GEARBOX |

|

|

|

| ||

|

|

| - |

|

|

|

|

| ||

|

| U | A |

|

|

|

|

|

|

|

| 115V | C |

|

|

|

|

|

|

| |

|

| B | H |

|

|

|

|

|

|

|

|

|

|

| W |

|

|

|

|

| TO |

|

|

|

|

|

|

|

|

| WORK | |

R1 | 40 OHMS |

|

|

|

|

|

|

|

|

|

| 50 W |

|

|

|

|

|

|

|

|

|

1108A ![]() 8

8 ![]()

J1

1109A ![]() 9

9 ![]()

1110A ![]() 10

10 ![]()

1111A ![]() 11

11 ![]()

1112A ![]() 12

12 ![]()

1113A ![]() 13

13 ![]()

1114A ![]() 14

14 ![]()

1115A ![]() 15

15 ![]()

1116A ![]() 16

16 ![]()

OPTION | 1 |

|

5 |

| |

| 2 |

|

| 3 | J2 |

| 4 | |

|

| |

FOR SPOOL GUN | 6 |

|

1 | J3 | |

| 2 |

|

Return to Section

Return to Master

OUTPUT

CHOKE | R.F. FILTER |

E

L12184PRINT

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The wiring diagram specific to your code is pasted inside one of the enclosure panels of your machine.