Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

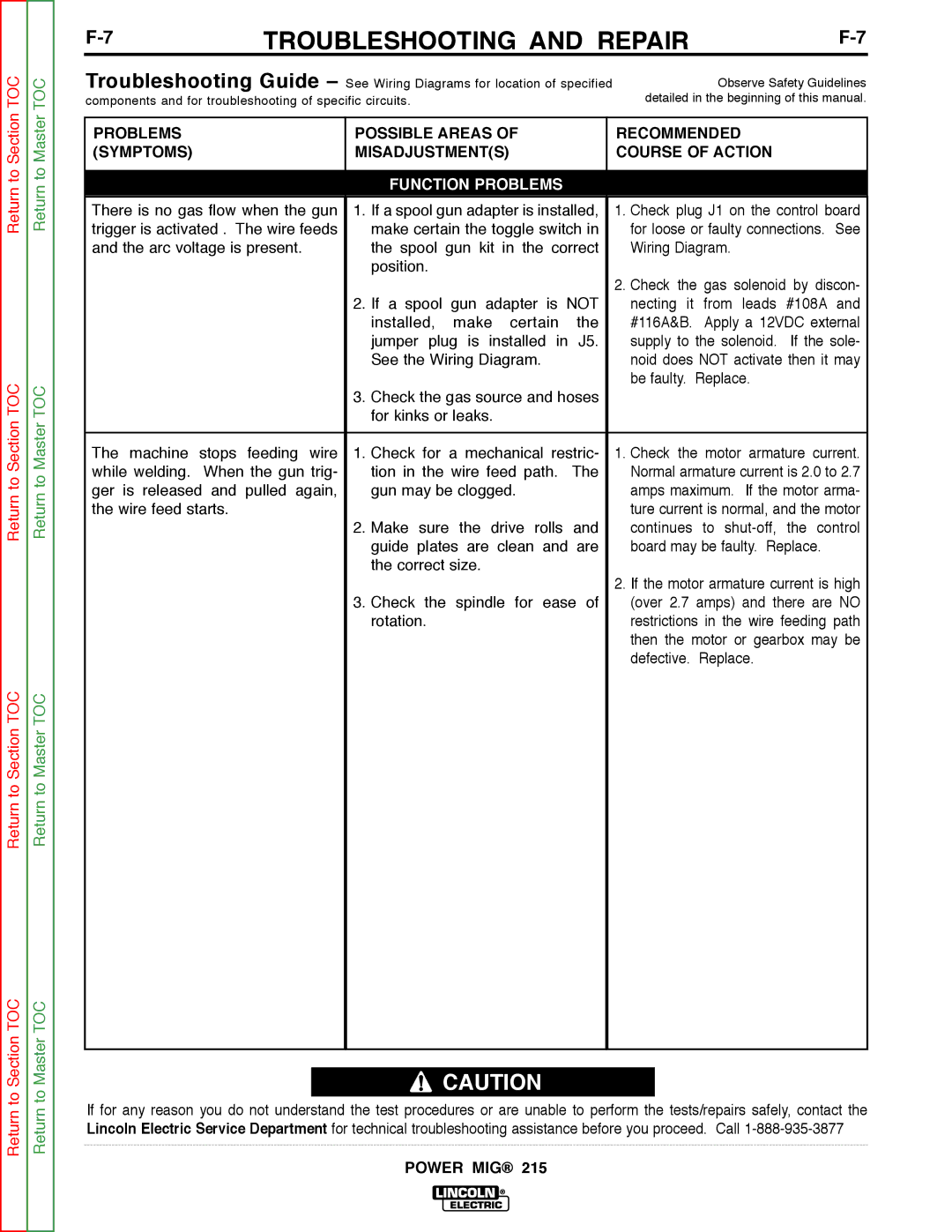

| TROUBLESHOOTING AND REPAIR | ||||||

|

|

|

|

|

|

|

|

Troubleshooting Guide – See Wiring Diagrams for location of specified | Observe Safety Guidelines | ||||||

components and for troubleshooting of specific circuits. |

|

| detailed in the beginning of this manual. | ||||

|

|

|

|

|

|

|

|

PROBLEMS |

| POSSIBLE AREAS OF |

|

| RECOMMENDED |

| |

(SYMPTOMS) |

| MISADJUSTMENT(S) |

|

| COURSE OF ACTION |

| |

|

|

|

|

|

|

|

|

|

|

| FUNCTION PROBLEMS |

|

|

|

|

|

|

|

|

| |||

There is no gas flow when the gun | 1. If a spool gun adapter is installed, |

| 1. Check plug J1 on the control board | ||||

trigger is activated . The wire feeds | make certain the toggle switch in |

| for loose or faulty connections. See | ||||

and the arc voltage is present. | the spool gun kit in the correct |

| Wiring Diagram. |

| |||

|

|

| position. |

|

|

|

|

|

|

|

|

|

| 2. Check the gas solenoid by discon- | |

|

|

| 2. If a spool gun adapter is NOT |

| necting it from leads #108A and | ||

|

|

| installed, make certain | the |

| #116A&B. Apply a 12VDC external | |

|

|

| jumper plug is installed in J5. |

| supply to the solenoid. | If the sole- | |

|

|

| See the Wiring Diagram. |

|

| noid does NOT activate then it may | |

|

|

|

|

|

| be faulty. Replace. |

|

|

|

| 3. Check the gas source and hoses |

|

|

| |

|

|

| for kinks or leaks. |

|

|

|

|

|

|

|

| ||||

The machine stops feeding wire | 1. Check for a mechanical restric- |

| 1. Check the motor armature current. | ||||

while welding. | When the gun trig- | tion in the wire feed path. | The |

| Normal armature current is 2.0 to 2.7 | ||

ger is released and pulled again, | gun may be clogged. |

|

| amps maximum. If the motor arma- | |||

the wire feed starts. |

|

|

| ture current is normal, and the motor | |||

|

|

| 2. Make sure the drive rolls and |

| continues to | ||

|

|

| guide plates are clean and are |

| board may be faulty. Replace. | ||

|

|

| the correct size. |

|

|

|

|

|

|

|

|

|

| 2. If the motor armature current is high | |

|

|

| 3. Check the spindle for ease of |

| (over 2.7 amps) and there are NO | ||

|

|

| rotation. |

|

| restrictions in the wire feeding path | |

|

|

|

|

|

| then the motor or gearbox may be | |

|

|

|

|

|

| defective. Replace. |

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call